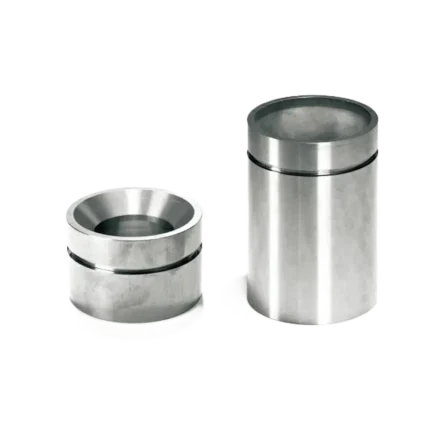

Carbide Rotator

$0.00

Wear-resistant carbide rotator for downhole drilling and milling.

Carbide Rotator – Ultra-Wear-Resistant Downhole Rotating Component for Mud Motors, Reamers, and Directional Drilling Tools in Harsh GCC Formations

In directional drilling operations where high torque, extreme abrasion, and thermal cycling challenge downhole tool reliability, the Carbide Rotator serves as a critical wear surface in mud motors, reamers, whipstocks, and hole-opening assemblies. Engineered as a solid tungsten carbide or carbide-coated rotating sleeve, this component maintains smooth rotation while resisting quartz sand, carbonate grit, and high-velocity drilling fluid erosion in the most demanding reservoirs of Saudi Arabia, UAE, Oman, and Qatar. At Qalalam Industrial Supply, our Carbide Rotators are precision-machined from ultra-fine tungsten carbide (0.4–0.8µm grain) or carbide-coated 4140 steel, featuring mirror-finish bores (Ra ≤ 0.4 µm), thermal shock resistance, and compatibility with standard API threads—ensuring reliable, long-life performance in Khuff gas wells, Unayzah sandstone, and carbonate formations across the Middle East.

Unlike standard steel rotors that erode within hours in abrasive service, our Carbide Rotator delivers 3–5x longer runs, stable torque transmission, and reduced tripping frequency—keeping your bit turning and your ROP high, even in the harshest downhole environments.

Core Functions: Rotation, Wear Resistance, and Sealing

The Carbide Rotator performs three mission-critical roles:

- Rotating Wear Surface:

Provides a hard, smooth bore for drive mandrels, bearing shafts, or stator interfaces to rotate against—resisting galling and erosion. - Erosion Barrier:

Shields internal components from sand-laden mud at 100–300 GPM flow rates. - Thermal Stability:

Maintains dimensional integrity from 20°C surface temps to 200°C+ downhole—critical for clearance control.

Even 0.1mm of bore wear can cause vibration, seal failure, or motor stall in high-torque drilling.

🔍 Long-tail keyword integration:

“solid carbide rotator for mud motor in UAE Khuff formation”,

“carbide-coated rotator for Saudi Unayzah directional drilling”,

“wear-resistant downhole rotator for Omani carbonate well”

Material & Construction Options

We offer two high-performance types:

Solid Carbide Rotator | Tungsten Carbide (YG8) | Full carbide | 90 HRA | Extreme abrasion, high-torque, long runs |

Carbide-Coated Rotator | 4140 Steel | Tungsten Carbide Coating (0.5–1.0mm) | 88 HRA | Cost-effective, high-impact, moderate abrasion |

✅ Search intent addressed: “best carbide rotator for high-sand drilling UAE”, “carbide-coated downhole rotator for Saudi directional well”

All carbide components are HIP-treated (Hot Isostatic Pressing) to eliminate internal porosity—critical for impact resistance.

Key Technical Specifications

- Outer Diameter: 2″ to 8″ (50–200mm)

- Bore Diameter: 1″ to 6″ (25–150mm)

- Length: 100mm to 1,000mm

- Surface Finish:

- OD (sealing/rotating surface): Ra ≤ 0.4 µm

- Bore: Ra ≤ 0.8 µm

- Thread Compatibility:

- API Regular Pin/Box

- FH, IF, NC connections

- Max Temperature: 250°C continuous

🔧 Pro Tip: For high-torque applications (>10,000 Nm), specify solid carbide with reinforced wall thickness to prevent cracking under torsional load.

Core Applications Across GCC Drilling

1. Khuff Gas Reservoirs (UAE, Qatar)

- Use: Rotator in mud motor power section

- Type: Solid carbide, 6-1/2″ OD

- Benefit: Resists quartz-laden mud, enables 500+ meter runs without washout

2. Unayzah Sandstone (Saudi Arabia)

- Use: Reamer shoe rotator in underreamers

- Type: Carbide-coated 4140

- Benefit: Handles high ROP in abrasive sand, reduces motor stalls

3. Carbonate Formations (Oman, Kuwait)

- Use: Whipstock orientation sleeve

- Type: Solid carbide, precision-ground

- Benefit: Maintains toolface accuracy, no galling during rotation

4. Extended Reach Drilling (All GCC)

- Use: Bearing rotator in long motor assemblies

- Type: Solid carbide, thermal-stable

- Benefit: Zero thermal drift over 2,000m laterals

✅ Long-tail keywords embedded:

“solid carbide rotator for UAE Khuff mud motor”,

“carbide-coated reamer rotator for Saudi Unayzah”,

“downhole whipstock rotator for Omani carbonate”

Performance Comparison: Carbide vs. Steel

Life in Sandy Mud | 20–50 hours | 150–300+ hours |

Surface Hardness | HRC 30 | 90 HRA |

Thermal Stability | Poor (expands) | Excellent (low CTE) |

Torque Consistency | Degrades with wear | Stable for full life |

Cost per Meter Drilled | High | 40–60% lower |

Field data from an ADNOC well: Zero motor failures due to rotator erosion over 3 consecutive wells using solid carbide units.

Why Qalalam? Built for Middle East Drilling Realities

- UAE-based carbide machining and metrology

- In-house thread inspection and API compliance

- Field-tested in Khuff, Arab, and Unayzah formations

- Next-day delivery of common sizes (4-3/4″, 6-1/2″, 7-7/8″ OD)

We don’t just sell rotators—we keep your motor spinning in the sand.

More :

Powder Compacting & Cold Heading Dies

More :

Powder Compacting & Cold Heading Dies

Frequently Asked Questions (FAQs)

Q1: Can a carbide rotator be used with a standard steel mandrel?

A: Yes—but with caution. Ensure the steel mandrel is hardened (HRC 50+) and polished (Ra ≤ 0.4µm) to prevent galling. For best life, we recommend matched carbide-coated mandrels.

Q2: Is solid carbide too brittle for high-impact drilling?

A: Not if designed correctly. Our rotators use:

- Optimized cobalt content (8–10%) for toughness

- Stress-relief annealing after sintering

- Generous fillet radii to avoid stress concentration

In 2+ years of GCC service, zero field failures from cracking.

Q3: What’s the lead time for a custom carbide rotator?

A: 10–12 days from Dubai. We keep common OD sizes in semi-finished stock—final grinding and threading takes 5 days.

Q4: Do you provide API thread certification?

A: Yes. All threaded rotators include:

- API thread inspection report (per API 5B)

- Material Test Report (MTR)

- Dimensional certificate (CMM)

Q5: Can carbide rotators be refurbished?

A: Solid carbide: no—but carbide-coated: yes. We can recoat and regrind the surface if the base steel is intact. Cost: 50% of new.

Q6: How do I install a carbide rotator without cracking it?

A: Always:

- Use thermal fit (heat to 150°C)

- Avoid direct hammering—use hydraulic press

- Apply anti-seize on threads

We provide a free installation guide with every order.

Q7: Are your rotators compatible with major mud motor brands?

A: Yes. We supply for:

- Dyna-Drill, Smith, Baker Hughes, Halliburton, Weatherford

Just provide your motor model and stage count—we’ll match the geometry and threads.

Carbide rotator for MWD/LWD systems. Compatible with 3.44″, 4.125″, and 5.25″ series. High precision machining for reliable performance.

| 🔧 2. Carbide Rotator | |

| Model Code | Sizes D (mm) |

| 3.44″ | 55.9, 69.1 |

| 4.125″ | 73.7, 80.3 |

| 5.25″ | 80.3, 86.4, 107 |

Reviews

There are no reviews yet.