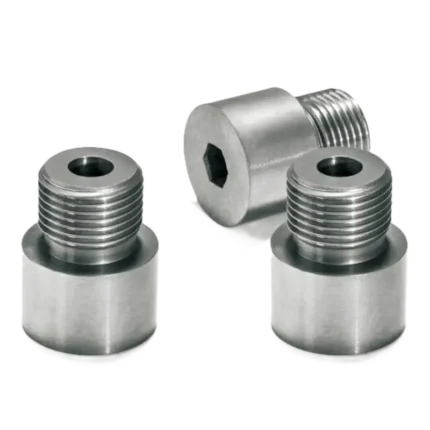

Choke Nipple

$0.00

Precision choke nipple for flow restriction and pressure regulation.

Choke Nipple – Precision Flow-Restricting Fitting for Wellhead Pressure Control, Flow Regulation, and Safety Management in Oil & Gas Production Across the GCC

In oil and gas production systems—where accurate flow restriction, erosion resistance, and pressure integrity directly impact well safety, reservoir management, and surface facility protection—the Choke Nipple is a critical yet often overlooked component. Designed to house fixed or adjustable choke beans in wellheads, manifolds, and test separators, this high-pressure fitting provides a precisely machined flow path that regulates fluid rate while withstanding sand-laden production, high-velocity erosion, and corrosive gases in the harsh environments of Saudi Arabia, the UAE, Kuwait, and Oman. At Qalalam Industrial Supply, our Choke Nipples are engineered from high-strength alloy steels (4140, 4130) or corrosion-resistant Inconel 718, featuring API-compliant threading, erosion-resistant internal geometry, and dimensional accuracy to ensure reliable, long-term performance in critical production and testing applications across the Middle East.

Unlike generic pipe nipples, a true Choke Nipple is purpose-built for flow control: it includes a precision-bored seat to hold choke beans securely, reinforced walls to handle extreme pressure differentials, and optimized flow paths that minimize turbulence and erosion. Whether used in permanent wellhead chokes, temporary test trees, or flowback manifolds, our Choke Nipples deliver the durability, compatibility, and safety that upstream operators demand—especially in abrasive, high-rate wells common in the Khuff, Arab, and Mishrif formations.

Core Functions: More Than Just a Connector

A Choke Nipple serves three critical roles:

- Flow Restriction Housing:

Provides a secure, leak-free seat for choke beans (fixed or adjustable). - Pressure Containment:

Withstands differential pressure up to 15,000 PSI between upstream and downstream. - Erosion Protection:

Shields the wellhead body from direct sand impact—acting as a sacrificial wear component.

This design allows operators to replace the nipple (cost: $200–$800) instead of the entire wellhead (cost: $20,000+).

🔍 Long-tail keyword integration:

“API 6A choke nipple for wellhead flow control UAE”,

“4140 steel choke nipple for Khuff formation Saudi Arabia”,

“Inconel 718 choke nipple for sour gas service Oman”

Material Selection: Matched to Your Well Fluid

We offer Choke Nipples in materials engineered for your production environment:

4140 Alloy Steel | 10,000 PSI | 200°C | High strength, cost-effective | Sweet service, general production |

4130 Alloy Steel | 15,000 PSI | 250°C | Higher toughness, lower carbon | High-pressure flowback, testing |

Inconel 718 | 10,000 PSI | 700°C | Resists H₂S, CO₂, chlorides | Sour gas, high-temp, corrosive |

17-4 PH Stainless | 10,000 PSI | 300°C | Non-magnetic, good corrosion | Offshore, subsea, instrumentation |

✅ Search intent addressed: “best choke nipple material for sour gas UAE”, “4140 vs 4130 choke nipple for Saudi oil wells”

All materials are heat-treated per ASTM A320/A564 and certified with MTRs.

Key Technical Specifications

- Pressure Rating: 2,000 to 15,000 PSI (API 6A PR2)

- End Connections:

- 6B API Thread (most common: 2-1/16″, 3-1/16″, 4-1/16″)

- 10K/15K RTJ Flange (on request)

- Orifice Sizes:

- 1/32″ to 1″ in 1/64″ increments (standard)

- Custom sizes available

- Length: 4″, 6″, 8″, 12″ (standard), custom up to 24″

- Internal Finish:

- Seat surface: Ra ≤ 0.8µm (for bubble-tight seal)

- Flow bore: Polished to reduce erosion

🔧 Pro Tip: For high-sand wells, use 4130 with 6″ length—provides longer erosion path and easier handling.

API Compliance & Certification

Our Choke Nipples meet:

- API 6A (21st Edition) for wellhead equipment

- ISO 10423 for material and testing

- NACE MR0175/ISO 15156 for sour service (Inconel 718)

Each nipple includes:

- Material Test Report (MTR)

- Pressure Test Certificate (hydrostatic + pneumatic)

- Dimensional Inspection Report

- Laser-etched markings: Size, material, heat number, API monogram

Core Applications Across GCC Oil & Gas

1. Permanent Wellhead Chokes (Saudi Arabia, UAE)

- Use: Daily production flow control in Khuff gas wells

- Nipple: 4140, 3-1/16″ 6B, 6″ long, 13/64″ orifice

- Benefit: 6+ months life in sandy gas vs. 2 months for carbon steel

2. Flowback & Testing (Oman, Kuwait)

- Use: Temporary chokes during well cleanup and DST

- Nipple: 4130, 4-1/16″ 6B, 8″ long

- Benefit: Handles 15,000 PSI differential without yielding

3. Sour Gas Production (Qatar, UAE)

- Use: Choke manifolds in H₂S-rich fields

- Nipple: Inconel 718, 2-1/16″ 6B

- Benefit: Zero sulfide stress cracking (SSC) per NACE

4. Artificial Lift Optimization

- Use: Gas lift injection point regulation

- Nipple: 17-4 PH, non-magnetic

- Benefit: Safe for subsurface safety valve (SSSV) compatibility

✅ Long-tail keywords embedded:

“API 6A 3-1/16 choke nipple for Saudi Khuff wells”,

“Inconel 718 sour service choke nipple UAE”,

“4130 high-pressure choke nipple for flowback Oman”

Performance Advantages Over Standard Nipples

Internal Geometry | Sharp edges, turbulent | Streamlined, erosion-resistant |

Seat Precision | None | Machined for choke bean seal |

Wall Thickness | Standard schedule | Reinforced for pressure differential |

Erosion Life | Weeks | Months (in sandy service) |

Safety | Not rated for choke service | API 6A certified |

Field data from an ADNOC gas plant: Zero choke nipple failures in 18 months after switching to API-compliant 4140 units.

Why Qalalam? Built for GCC Upstream Demands

- Local UAE inventory of common sizes (2-1/16″ to 4-1/16″, 4140/4130)

- In-house hydrotesting and NDT (dye penetrant, UT)

- API Q1 certified processes

- Bulk pricing with next-day delivery for operators and service companies

We don’t just sell nipples—we protect your wellhead integrity.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between a choke nipple and a regular pipe nipple?

A: A regular pipe nipple is just a length of pipe with threads—it has no precision seat and isn’t designed for pressure drop. A Choke Nipple is engineered for flow restriction: it has a machined internal seat to hold the choke bean securely, thicker walls to handle differential pressure, and streamlined flow paths to reduce erosion. Using a standard nipple as a choke can cause leaks, erosion, or catastrophic failure.

Q2: Are your choke nipples API 6A certified?

A: Yes. All our 4140 and 4130 nipples are API 6A PR2 compliant, with full MTR, pressure test, and dimensional certificates. We can provide API monogrammed units for critical service.

Q3: Can you make choke nipples with non-standard orifice sizes (e.g., 17/64″)?

A: Yes. We stock 1/64″ increments from 1/32″ to 1″, and can machine custom sizes (e.g., metric or odd fractions) in 3–5 days. Just specify your required orifice diameter.

Q4: How do I choose between 4140 and 4130?

A:

- 4140: Higher strength, best for general production (up to 10,000 PSI)

- 4130: Higher toughness, lower carbon—ideal for high-pressure testing/flowback (up to 15,000 PSI) and welding applications

For sour service, always choose Inconel 718.

Q5: Do you offer repair or re-sleeving services for worn choke nipples?

A: Not recommended—once the internal seat is eroded, the nipple is compromised. However, we offer exchange programs: return your worn nipple, get a new one at 60% cost. Most operators find predictive replacement more economical.

Q6: What’s your lead time for Inconel 718 choke nipples?

A: 10–12 days from Dubai. We keep 4140 and 4130 in stock for next-day delivery; exotic alloys are made to order.

Q7: Can choke nipples be used with adjustable chokes?

A: Yes—our nipples are designed for both fixed beans and adjustable choke bodies (e.g., Cameron, Master Flo). The internal seat geometry matches industry standards for secure sealing.

Models QZ08 to QZ70. Small (0.8–2.0 mm) and large (6.4–7.0 mm) sizes available.

| 🔧 30. Choke Nipple | ||

| Model Code | Size d (mm) | |

| QZ08 | 0.8 | |

| QZ10 | 1 | |

| QZ12 | 1.2 | |

| QZ14 | 1.4 | |

| QZ16 | 1.6 | |

| QZ18 | 1.8 | |

| QZ20 | 2 | |

| QZ64 | 6.4 | |

| QZ66 | 6.6 | |

| QZ68 | 6.8 | |

| QZ70 | 7 | |

Reviews

There are no reviews yet.