Flow Limitation Sleeve

$0.00

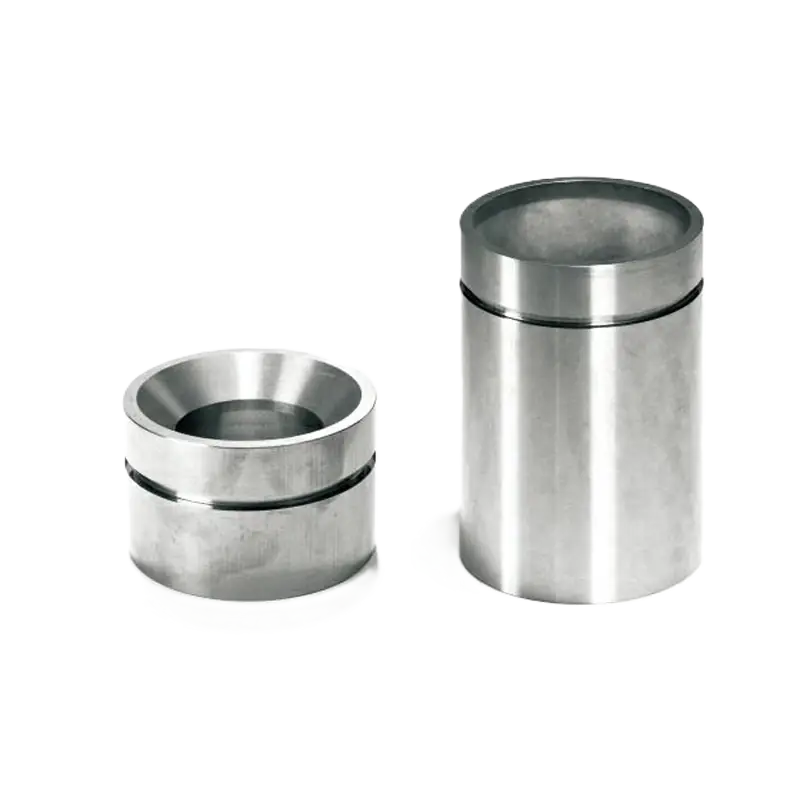

Sleeve-based flow limiter for integration into manifolds and blocks.

Flow Limitation Sleeve – Precision Passive Flow Restrictor for Hydraulic Manifolds, Cartridge Valves, and Integrated Circuits in Industrial Machinery Across the GCC

In compact hydraulic and fluid power systems—where space is limited but precise flow control, overload protection, and energy efficiency are critical—the Flow Limitation Sleeve delivers a simple, reliable, and maintenance-free solution. Designed as a drop-in insert for manifold cavities or cartridge valve bodies, this passive flow restrictor uses a fixed, calibrated orifice to cap maximum fluid flow, protecting downstream components like actuators, motors, and sensors from damage due to excessive speed or pressure surges. From mobile hydraulic systems in UAE construction equipment and industrial presses in Saudi Arabia to injection molding machines in Qatar and material handling systems in Oman, Qalalam Industrial Supply’s Flow Limitation Sleeves are precision-manufactured from stainless steel 316, carbon steel, or brass, featuring laser-drilled orifices (±0.01mm tolerance), leak-tight sealing lands, and standard cavity compatibility—ensuring dependable performance in the most demanding Middle Eastern industrial environments.

Unlike electronic flow controls or complex valves, the Flow Limitation Sleeve is inherently fail-safe: it has no moving parts, no electronics, and no drift—making it ideal for harsh, remote, or hazardous applications where reliability and simplicity are paramount. Whether used for cylinder speed control, pump protection, circuit balancing, or safety compliance, this sleeve provides consistent, tamper-proof flow limitation for years with zero maintenance.

Core Function: Passive Flow Control in Minimal Space

The Flow Limitation Sleeve performs one critical task with maximum efficiency:

- Fixed Orifice Flow Restriction:

Limits flow to a predetermined rate—regardless of pressure fluctuations—by forcing fluid through a precision-drilled orifice. - Integrated Design:

Fits directly into SAE, ISO 4401, or CETOP manifold cavities—no extra plumbing or external valves needed. - Thermal & Pressure Stability:

Maintains performance from –20°C to 120°C and up to 350 bar.

Because it’s monolithic and passive, it cannot fail, jam, or require recalibration.

🔍 Long-tail keyword integration:

“flow limitation sleeve for hydraulic manifold UAE”,

“cartridge flow restrictor sleeve for Saudi industrial press”,

“CETOP-compatible flow limiter sleeve for Qatar injection molding”

Material Selection: Matched to System Fluid and Pressure

We offer Flow Limitation Sleeves in materials engineered for your hydraulic or process fluid:

Brass | 210 bar | 120°C | General industrial, cost-sensitive, water-glycol |

Carbon Steel | 350 bar | 120°C | Mobile hydraulics, high-pressure oil systems |

SS 316/316L | 350 bar | 150°C | Food-grade, seawater, corrosive environments, washdown |

✅ Search intent addressed: “best flow limitation sleeve material for seawater hydraulic system”, “carbon steel cartridge flow restrictor for UAE excavator”

All orifices are laser-drilled—not EDM or mechanical—to ensure smooth, burr-free flow paths and exact Cv values.

Key Technical Specifications

- Orifice Diameter: 0.3mm to 5.0mm (standard), custom up to 8mm

- Orifice Tolerance: ±0.01mm (laser-measured)

- Cavity Compatibility:

- CETOP 03, 05, 07 (ISO 4401)

- SAE 8, 10, 12

- Custom manifolds (provide drawing)

- Sealing Lands:

- O-ring grooves (AS568 standard)

- Metal-to-metal seats (for high-temp)

- Pressure Rating: Up to 350 bar (5,000 PSI)

🔧 Pro Tip: For high-viscosity fluids, use orifices ≥1.5mm. For fine speed control, specify ±0.005mm tolerance—we provide Cv calibration reports on request.

Core Applications Across GCC Industries

1. Mobile Hydraulics (UAE, Oman)

- Use: Limiting boom extension speed on excavators and cranes

- Sleeve: Carbon steel, CETOP 05, 1.2mm orifice

- Benefit: Prevents load drop accidents, meets safety regulations

2. Industrial Presses (Saudi Arabia, Kuwait)

- Use: Controlling ram descent speed in stamping presses

- Sleeve: Carbon steel, SAE 10, 2.0mm orifice

- Benefit: Ensures repeatable cycle times, protects dies

3. Injection Molding (Qatar, Bahrain)

- Use: Balancing flow to multiple mold cavities

- Sleeve: SS 316, CETOP 03, 0.8mm orifice

- Benefit: Improves part consistency, reduces scrap

4. Food & Beverage (Dubai, Abu Dhabi)

- Use: Washdown system flow control

- Sleeve: Electropolished SS 316L

- Benefit: Meets 3-A and FDA 21 CFR standards

✅ Long-tail keywords embedded:

“CETOP 05 flow limitation sleeve for UAE excavator hydraulic”,

“carbon steel cartridge flow restrictor for Saudi stamping press”,

“SS 316 flow limiter sleeve for Qatar injection molding machine”

Advantages Over External Flow Controls

Space Required | High (plumbing, mounting) | Medium | None (inside manifold) |

Leak Points | 2–4 | 2 | 0 (integrated) |

Tamper-Proof | No | No | Yes |

Maintenance | Required | Medium | Zero |

Cost per Function | High | Medium | Low |

Field feedback from a Dubai equipment OEM: “Reduced manifold size by 30% and eliminated 2 leak points per circuit.”

Why Qalalam? Compact Control, Local Support

- UAE inventory of common CETOP/SAE sizes (CETOP 03–07, SAE 8–12)

- In-house laser drilling and flow testing

- Custom orifice calibration (Cv curve provided)

- Next-day delivery across GCC

We don’t just sell sleeves—we integrate safety and efficiency into your manifold.

Frequently Asked Questions (FAQs)

Q1: Can I clean a flow limitation sleeve if it gets clogged?

A: Yes—easily. Because it’s a straight-through orifice, you can:

- Ultrasonic clean in 10 minutes

- Blow through with air

- Rod with soft wire (no metal!)

No disassembly needed—just remove from the manifold.

Q2: How do I choose the right orifice size for my application?

A: Provide:

- Desired flow rate (L/min)

- Fluid type and viscosity

- Max pressure drop available (bar)

We’ll calculate the exact orifice and provide a flow performance chart.

Q3: Are your sleeves compatible with all manifold manufacturers?

A: Yes—for standard cavities. We match:

- Parker, Bosch Rexroth, Danfoss, HydraForce, Sun Hydraulics

Just specify your manifold model or cavity standard.

Q4: Can you make sleeves with multiple orifices?

A: Yes. We produce:

- Dual-orifice sleeves (for bi-directional circuits)

- Series orifices (for high ΔP, low noise)

- Custom porting (send your drawing)

Q5: Do flow limitation sleeves create heat in the system?

A: Yes—but controlled. Like all flow restrictions, they convert pressure to heat. To minimize:

- Use the largest orifice that meets your speed requirement

- Ensure adequate reservoir cooling

We can help size your system for thermal balance.

Q6: What’s your lead time for custom orifice sleeves?

A: 3–5 days from Dubai. Laser drilling is fast—we can produce any size from 0.3mm with full calibration.

Q7: Can these sleeves be used in water-glycol or HFDU fluids?

A: Yes. For water-based fluids, we recommend:

- Stainless steel 316 (resists corrosion)

- Electropolished surface (prevents particle adhesion)

Avoid carbon steel in water-glycol—it will rust.

Internal dimension: 227724c±0.5. Used in MWD flow regulation systems.

| 🔧 13. Lower Stator | ||||

| Model Code | H (mm) | D (mm) | D1 (mm) | R (mm) |

| XLT35 | 53 | 50 | 35 | 5 |

| XLT46 | 67 | 68 | 43 | 5 |

| XLT70 | 140 | 99 | 66 | 15 |

Reviews

There are no reviews yet.