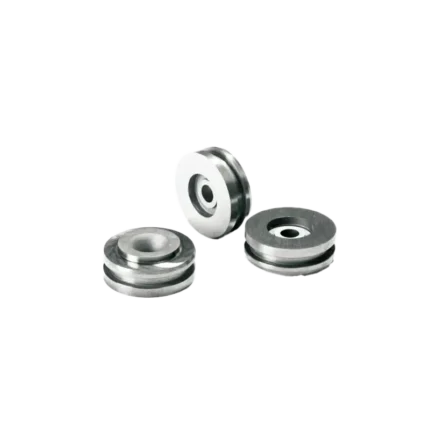

Flow Seat Spacer Sleeve

$0.00

Integrated sleeve for flow seat alignment and spacing in control valves.

Flow Seat Spacer Sleeve – Precision Engineered Sleeve for Critical Clearance Control and Flow Path Alignment in Control Valves, Manifolds, and Hydraulic Systems Across GCC Oil, Gas, and Process Industries

In high-performance fluid control systems—where micron-level clearances, leak-tight sealing, and stable flow characteristics directly impact process efficiency, safety, and emissions compliance—the Flow Seat Spacer Sleeve is a mission-critical component that ensures exact positioning between valve seats, flow restrictors, and sealing elements. Designed for use in multi-port control valves, instrument manifolds, choke assemblies, and safety shutdown systems, this precision sleeve maintains critical axial gaps that govern flow rate, pressure drop, and valve responsiveness in the demanding environments of UAE refineries, Saudi gas processing plants, Qatari LNG facilities, and Omani petrochemical complexes. At Qalalam Industrial Supply, our Flow Seat Spacer Sleeves are manufactured from stainless steel 316/316L, Inconel 625, or Duplex 2205, featuring tight length tolerances (±0.01mm), mirror-finish sealing surfaces, and thermal expansion-matched geometry—ensuring reliable, drift-free performance even under high-pressure, high-temperature, and corrosive service conditions.

Unlike generic spacers, the Flow Seat Spacer Sleeve is engineered as an integral part of the flow control system, where even 0.05mm of excess length can cause valve binding, seat leakage, or unstable flow modulation. Whether used in Fisher, Masoneilan, Crane, or Flowserve control valves, our sleeves provide the dimensional stability, corrosion resistance, and repeatability that process engineers and maintenance teams depend on for safe, efficient operation.

Core Functions: Precision Spacing in Critical Flow Paths

The Flow Seat Spacer Sleeve performs three essential roles:

- Axial Clearance Control:

Maintains exact distance between valve seat and flow restrictor or poppet and seat—critical for Cv accuracy and low hysteresis. - Thermal Isolation:

Minimizes heat transfer between hot process fluid and sensitive actuator components. - Sealing Surface Support:

Provides a flat, parallel reference for soft or metal seats to achieve bubble-tight shut-off.

In control valves, this sleeve is often the difference between Class IV and Class VI leakage performance.

🔍 Long-tail keyword integration:

“flow seat spacer sleeve for Fisher control valve UAE”,

“Inconel 625 spacer sleeve for Saudi gas processing manifold”,

“precision flow restrictor sleeve for Qatar LNG choke valve”

Material Selection: Matched to Fluid and Temperature

We offer Flow Seat Spacer Sleeves in materials engineered for your process:

SS 316/316L | 500°C | Excellent corrosion resistance | General process, water, mild chemicals |

Duplex 2205 | 300°C | High strength + chloride resistance | Seawater, desalination, offshore |

Inconel 625 | 800°C | Resists H₂S, CO₂, oxidation | Sour gas, high-temp refining, LNG |

Hastelloy C276 | 1,000°C | Resists acids, chlorides, pitting | Chemical injection, acid service |

✅ Search intent addressed: “best spacer sleeve material for sour gas control valve”, “Inconel 625 flow seat sleeve for UAE LNG”

All sleeves are solution-annealed and stress-relieved to prevent distortion in service.

Precision Manufacturing: Tolerances That Ensure Valve Performance

Our production process ensures valve-grade accuracy:

- Length Tolerance: ±0.01mm (standard), ±0.005mm (high-precision)

- Flatness: ≤ 0.005mm per face

- Parallelism: ≤ 0.01mm

- Surface Finish:

- Sealing faces: Ra ≤ 0.2µm (lapping standard)

- OD/ID: Ra ≤ 0.8µm

- Edge Break: 0.05mm radius (prevents seal hang-up)

🔧 Why it matters: In a Class VI control valve, a 0.02mm warp causes measurable leakage—failing tightness tests and increasing fugitive emissions.

Core Applications Across GCC Industries

1. Oil & Gas Refining (UAE, Saudi)

- Use: Spacer sleeves in Fisher EVD and FIELDVUE control valves

- Sleeve: SS 316L, ±0.01mm tolerance

- Benefit: Ensures precise Cv control for distillation column pressure regulation

2. LNG & Gas Processing (Qatar, Oman)

- Use: Inconel sleeves in cryogenic and high-pressure letdown valves

- Sleeve: Inconel 625, Ra 0.2µm

- Benefit: Resists thermal cycling from -160°C to 200°C without drift

3. Petrochemical (Kuwait, Bahrain)

- Use: Manifold spacer sleeves for reactor pressure control

- Sleeve: Hastelloy C276

- Benefit: Withstands acidic catalyst streams without corrosion

4. Power & Desalination (Dubai, Abu Dhabi)

- Use: Feedwater control valve spacers

- Sleeve: SS 316L, lapped faces

- Benefit: Prevents leakage in 1,000 PSI, 250°C service

✅ Long-tail keywords embedded:

“SS 316 flow seat spacer for Fisher valve UAE”,

“Inconel 625 control valve sleeve for Qatar LNG”,

“Hastelloy C276 spacer sleeve for Kuwait petrochemical manifold”

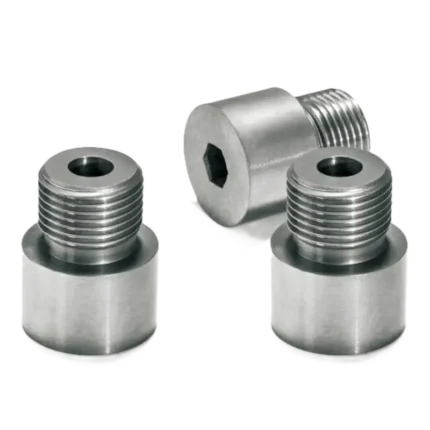

OEM Compatibility & Replacement

We maintain cross-references for major valve brands:

- Fisher: EVD, FIELDVUE, 8580

- Masoneilan: 1000, 2000 series

- Crane: SA, SAB

- Flowserve: Valtek, Kämmer

Just provide:

- Valve model and size

- Service conditions (fluid, T, P)

- Old sleeve dimensions (or part number)

We deliver a direct-fit, certified replacement—often with upgraded material for longer life.

Why Qalalam? Precision Fluid Control, Local Support

- UAE-based metrology lab (CMM, flatness tester, profilometer)

- Full material traceability (MTR with every order)

- Valve engineer support for critical applications

- Next-day delivery of common sizes (10–50mm length)

We don’t just sell sleeves—we ensure your valves control precisely.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between a flow seat spacer and a standard spacer sleeve?

A: A standard spacer only maintains distance. A Flow Seat Spacer Sleeve is a precision flow-critical component: it has lapped faces (Ra ≤ 0.2µm), ±0.01mm length tolerance, and parallelism ≤0.01mm—required for Class V/VI shut-off and stable Cv. Using a standard sleeve in a control valve causes leakage, hysteresis, or instability.

Q2: Can I reuse a flow seat spacer during valve overhaul?

A: Only if undamaged. Inspect for:

- Warping (use optical flat)

- Scratches on sealing faces

- Corrosion or erosion

If in doubt, replace it—a $50 sleeve prevents a $10,000 process upset.

Q3: Do your sleeves come with certification for API 6D or ISO 5208?

A: Yes. We provide:

- Material Test Report (MTR)

- Dimensional Inspection Certificate

- Surface Finish Report

All traceable to ISO 17025—accepted for API 6D, ISO 5208, and NORSOK audits.

Q4: Can you make sleeves with internal O-ring grooves?

A: Yes. We machine:

- Standard O-ring grooves (AS568, ISO 3601)

- Custom seal pockets for metal C-rings

Specify groove dimensions—we’ll hold ±0.02mm.

Q5: How do I choose between SS 316 and Inconel 625?

A:

- SS 316: For temperatures <500°C, non-sour service

- Inconel 625: For sour gas (H₂S), cryogenic, or >500°C service

When in doubt, send your process data sheet—we’ll recommend.

Q6: What’s your lead time for Inconel sleeves?

A: 7–10 days from Dubai. We keep SS 316 in stock for next-day delivery; exotic alloys are fast-tracked.

Q7: Are your sleeves compatible with soft (PTFE) and metal seats?

A: Yes. Our Ra ≤ 0.2µm finish works with:

- PTFE, graphite, PCTFE (soft seats)

- Stellite, carbide, Inconel (metal seats)

No hang-up, no leakage.

Reviews

There are no reviews yet.