Nose Cap

$0.00

Protective cap for drill bits, nozzles, and sensor tips.

Nose Cap – Protective End Cap for Drill Bits, Sensors, and Tooling Tips in Harsh Industrial and Oilfield Environments Across the GCC

In industrial handling, storage, and transportation—where precision tips, fragile edges, and calibrated surfaces are vulnerable to impact damage, contamination, and corrosion—the Nose Cap serves as a simple yet critical protective barrier. Designed to shield the cutting edges of drill bits, sensing tips of probes, nozzle orifices, and carbide inserts during non-operational periods, this small but essential component prevents costly damage that can compromise performance, accuracy, or safety. From PDC drill bits in Saudi oilfield logistics and CMM probe tips in UAE aerospace QA labs to waterjet nozzles in Qatari fabrication shops and carbide scrapers in Omani maintenance kits, Qalalam Industrial Supply delivers high-durability Nose Caps in impact-resistant polymers (UHMW-PE, PEEK), aluminum, or stainless steel 316, featuring custom-fit geometries, secure retention, and ESD-safe options—ensuring your high-value tooling arrives and remains in perfect condition across the demanding industrial landscape of the Middle East.

Unlike generic caps or makeshift covers, our Nose Caps are engineered to match your exact tool profile, providing snug, non-marring protection without risk of loss, slippage, or internal abrasion—making them indispensable for field service teams, warehouse operations, and precision manufacturing facilities across the GCC.

Core Functions: Protection, Preservation, and Professionalism

The Nose Cap performs three essential roles:

- Impact Protection:

Shields fragile tips from drops, knocks, and handling damage during transport or storage. - Contamination Prevention:

Seals out dust, moisture, oil, and chemicals that can degrade performance or cause corrosion. - Retention & Identification:

Features secure fit (snap, thread, or friction) and color-coding/laser marking for easy inventory management.

A single $5 Nose Cap can prevent $500 in tool replacement or hours of recalibration.

🔍 Long-tail keyword integration:

“protective nose cap for PDC drill bit UAE”,

“ESD-safe sensor tip cap for Saudi aerospace”,

“carbide nozzle protector for Qatar waterjet shop”

Material Selection: Matched to Tool and Environment

We offer Nose Caps in materials engineered for your protection needs:

UHMW-PE | High impact strength, chemical-resistant, non-marring | General industrial, drill bits, nozzles |

PEEK | High-temp (250°C), ESD-safe, ultra-clean | Aerospace, semiconductor, medical |

Aluminum | Lightweight, rigid, reusable | Field tooling, reusable protection |

SS 316 | Corrosion-proof, rugged, high-temp | Offshore, chemical, washdown environments |

✅ Search intent addressed: “best nose cap for carbide drill bit storage UAE”, “ESD-safe probe tip cap for Saudi QA lab”

All caps are non-sparking and compatible with sensitive surfaces.

Key Design Features

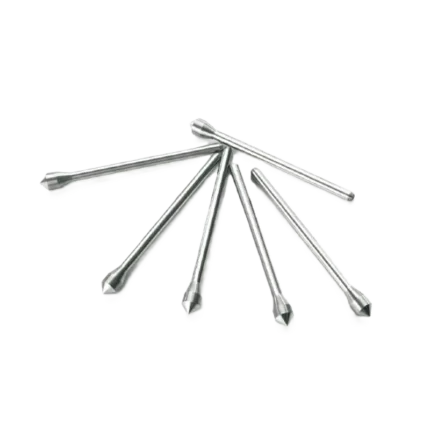

- Custom Tip Geometry:

- Conical (for drill bits)

- Spherical (for ball probes)

- Flat or recessed (for nozzles, scrapers)

- Retention Method:

- Friction-fit (for quick use)

- Snap-on (for secure hold)

- Threaded (for high-vibration environments)

- Surface Finish:

- Internal: Smooth, non-abrasive (Ra ≤ 1.6µm)

- External: Matte or textured for grip

- Identification:

- Color-coding by size

- Laser-etched part number or tool ID

🔧 Pro Tip: For carbide or diamond-coated tips, always use polymer caps—metal caps can cause micro-chipping on contact.

Core Applications Across GCC Industries

1. Oil & Gas (Saudi Arabia, UAE)

- Use: Protecting PDC and tricone drill bit cutters during transport

- Cap: UHMW-PE, conical, snap-on

- Benefit: Prevents carbide tip chipping, ensures first-run performance

2. Aerospace & Metrology (Qatar, Bahrain)

- Use: Shielding CMM and laser probe tips in QA labs

- Cap: ESD-safe PEEK, spherical

- Benefit: Meets AS9100 handling standards, prevents calibration drift

3. Manufacturing (Oman, Kuwait)

- Use: Nozzle and scraper tip protection in maintenance kits

- Cap: UHMW-PE, color-coded by size

- Benefit: Reduces tool damage in field use, improves inventory control

4. Semiconductor (Dubai, Abu Dhabi)

- Use: Sensor and wafer handler tip protection

- Cap: Cleanroom-grade PEEK, particle-free

- Benefit: Complies with SEMI F57, prevents contamination

✅ Long-tail keywords embedded:

“UHMW-PE nose cap for Saudi PDC drill bit”,

“ESD-safe probe cap for UAE aerospace QA”,

“color-coded nozzle protector for Qatar maintenance kit”

Customization: Built for Your Tool

We specialize in custom Nose Caps:

- Reverse-engineered from your tool tip

- 3D-scanned for perfect fit

- Material-matched to your environment

- Bulk packs with storage trays (optional)

💡 Design tip: For high-value tools, we recommend threaded SS 316 caps with O-ring seals—ideal for offshore or desert storage.

Why Qalalam? Protection You Can Trust

- UAE-based design and manufacturing

- In-house 3D scanning and prototyping

- ESD and cleanroom-certified options

- Next-day delivery of standard sizes

We don’t just sell caps—we protect your precision investment.

Frequently Asked Questions (FAQs)

Q1: Can I use a metal cap on a carbide drill bit?

A: Not recommended. Metal-on-carbide contact can cause micro-chipping. Use UHMW-PE or PEEK—they absorb impact without damaging the tip.

Q2: Do your caps meet ESD standards for electronics?

A: Yes. Our PEEK caps are available with surface resistivity 10⁴–10⁶ ohms/sq—compliant with ANSI/ESD S20.20 for semiconductor and aerospace use.

Q3: How do I choose between snap-on and friction-fit?

A:

- Friction-fit: For frequent use (e.g., daily tool changes)

- Snap-on: For transport and storage (won’t fall off)

- Threaded: For high-vibration or hazardous environments

Q4: Can you make caps for irregular or custom tool shapes?

A: Yes. Send us:

- Old cap

- Tool tip photo

- Or 3D scan

We’ll produce a perfect-fit cap in 5 days.

Q5: Are your caps reusable?

A: Yes—all materials are designed for 50+ uses. UHMW-PE and aluminum caps last years in field service.

Q6: What’s your lead time for custom nose caps?

A: 5–7 days from Dubai. We keep standard drill bit and nozzle caps in stock for next-day delivery.

Q7: Do you offer bulk packaging with organization trays?

A: Yes. We supply:

- Color-coded sets (e.g., 10 sizes in one case)

- Foam-lined storage trays

- Wall-mounted dispensers for workshops

Reviews

There are no reviews yet.