Blog

O-Ring Selection Guide: Material, Design

The Ultimate O-Ring Selection Guide: Insights from the Dichtomatik Handbook

O-rings are among the most versatile and widely used sealing components in industrial, automotive, aerospace, and hydraulic applications. Selecting the right O-ring is critical to ensuring leak-free performance, longevity, and system reliability. Drawing on principles from the Dichtomatik O-Ring Handbook by All Seals Inc., this guide provides engineers and maintenance professionals with actionable insights for optimal O-ring selection and application.

Why O-Ring Material Matters

The performance of an O-ring largely depends on its material compatibility with the operating environment. Common elastomers include:

- Nitrile (NBR): Ideal for oils and fuels; cost-effective for general-purpose use.

- FKM (Viton®): Excellent resistance to high temperatures and aggressive chemicals.

- EPDM: Best for steam, water, and brake fluids—but not for petroleum-based fluids.

- Silicone: Flexible at low temperatures; used in food, medical, and high-temp applications.

- PTFE (Teflon®): Chemically inert and suitable for extreme purity or corrosive environments.

Pro Tip: Always cross-reference your fluid type, temperature range, and pressure conditions with an elastomer compatibility chart—like those in the Dichtomatik Handbook—to avoid premature seal failure.

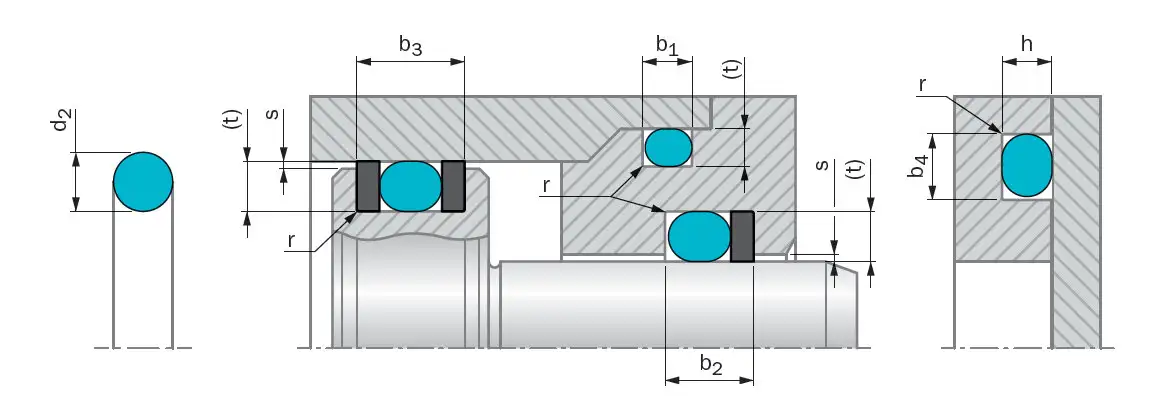

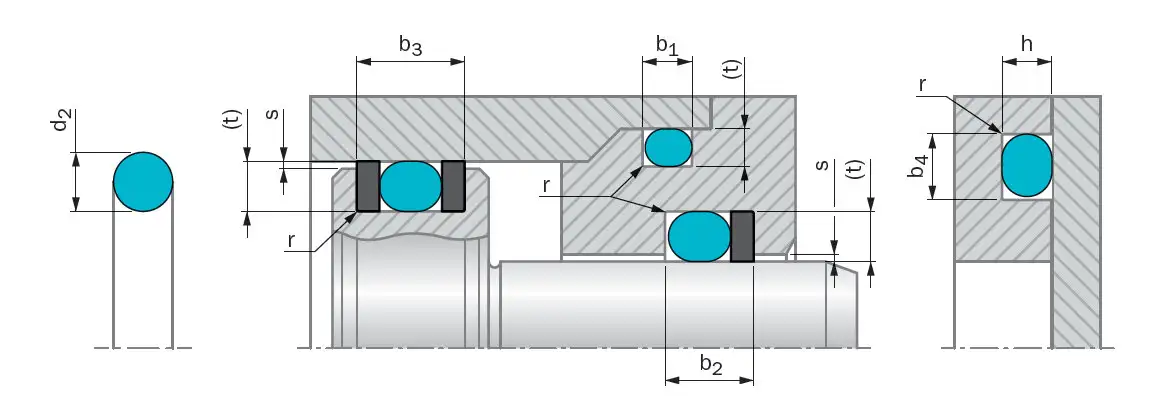

Correct O-Ring Sizing and Tolerances

An improperly sized O-ring can lead to extrusion, leakage, or excessive friction. Key dimensions include:

- Inside Diameter (ID)

- Cross-Section (CS)

- Groove dimensions (width and depth)

The Dichtomatik Handbook emphasizes proper gland design to ensure:

- Adequate compression (typically 15–30% for static seals, 10–20% for dynamic)

- Sufficient space to prevent over-compression

- Clearance to avoid extrusion under pressure

Use standardized sizing (e.g., AS568, ISO 3601) and consult tolerance tables to match hardware specifications.

Installation Best Practices

Even the highest-quality O-ring can fail if installed incorrectly. Follow these guidelines:

Read More :

Advanced Mechanical Seals Boosting Efficiency in Oil & Gas

Read More :

Advanced Mechanical Seals Boosting Efficiency in Oil & Gas

- Lubricate the O-ring and mating surfaces with a compatible lubricant.

- Avoid sharp edges on glands or shafts that could nick or tear the seal.

- Stretch minimally during installation—excessive stretching causes permanent set.

- Use installation tools for small or tight-tolerance applications to prevent twisting.

The Dichtomatik Handbook includes detailed diagrams and torque recommendations to support safe handling.

Common Failure Modes & How to Prevent Them

Understanding O-ring failure is key to improving system reliability. Typical issues include:

- Extrusion/Nibbling: Caused by high pressure and insufficient gland support. Use backup rings or harder durometer materials.

- Compression Set: Results from prolonged exposure to high temps. Switch to high-temp elastomers like FKM or FFKM.

- Chemical Degradation: Swelling, cracking, or hardening due to fluid incompatibility. Re-evaluate material choice.

- Abrasion: Common in dynamic seals. Ensure proper lubrication and surface finish (Ra < 0.4 µm recommended).

O-rings are fundamental components in countless mechanical systems, providing reliable and efficient sealing solutions. Among the various standards, the Inch Series O-rings, often defined by standards like AS568 (Aerospace Standard) and SAE J2077, hold significant importance, particularly in North American and other industries adhering to imperial measurements.

What Are Inch Series O-Rings?

Inch Series O-rings are standardized elastomeric seals characterized by their cross-sectional diameter (thickness) and inside diameter (ID), both measured in inches (or fractions thereof). Unlike metric O-rings which use millimeters, the dimensions of Inch Series O-rings follow specific charts established by standards organizations. This standardization ensures interchangeability and simplifies the selection process for engineers and maintenance professionals.

What Defines Metric Series O-Rings?

Unlike their inch-based counterparts, Metric Series O-rings are specified using the metric system for both their Inside Diameter (ID) and Cross-Sectional Diameter (CS). This straightforward metric sizing makes them incredibly intuitive for engineers and technicians working within the metric framework. You’ll often find them simply designated by their dimensions, for example, “O-Ring 10 x 2” (ID 10mm, CS 2mm).

Key Features & Benefits:

Standardization: Adherence to standards like AS568 guarantees precise dimensions, ensuring proper fit and effective sealing in grooves designed for specific cross-sections and IDs.

Wide Availability: Due to their widespread use, especially in aerospace, automotive, and general industrial sectors in the US, Inch Series O-rings are readily available from numerous suppliers globally.

Material Versatility: These O-rings are manufactured from a vast array of materials, including Nitrile (Buna-N), Viton® (FKM), EPDM, Silicone, Neoprene, and many others. This allows them to perform reliably across diverse temperature ranges and when exposed to various chemicals, oils, and fuels.

Reliable Sealing: The simple, effective design of the O-ring, combined with the precise dimensions of the Inch Series, makes them excellent for static and dynamic sealing applications, preventing leaks under pressure.

Cost-Effective: Their standardization and mass production make Inch Series O-rings a cost-effective sealing solution for a broad range of applications.

Common Applications:

Inch Series O-rings are found wherever reliable sealing is crucial. Typical applications include:

Hydraulic & Pneumatic Systems: Sealing cylinders, valves, pumps, and fittings.

Automotive: Fuel systems, power steering, engine components, transmissions.

Aerospace: Critical sealing applications where high performance and reliability are essential.

Plumbing & Fittings: Creating leak-proof joints in pipes and connectors.

Industrial Machinery: Sealing rotating shafts, static flanges, and housing covers.

Choosing the Right Inch Series O-Ring:

Selecting the correct O-ring involves understanding the specific requirements of your application:

Dimensions: Determine the required Inside Diameter (ID) and Cross-Section (CS) based on your groove dimensions. Referencing the AS568 chart is common for inch sizes.

Material: Choose the appropriate elastomer based on the operating temperature, pressure, and the media (fluids, gases) it will contact.

Operating Conditions: Consider factors like pressure cycling, abrasion, and whether the application is static or dynamic (involve movement).

Whether you’re designing a new system or replacing a seal, understanding the role and specifications of Inch Series O-rings is vital for achieving optimal performance and longevity. Their proven track record, standardization, and material diversity make them indispensable elements in achieving reliable sealing across numerous industries.

| Size Ref. | Inside Diameter | Tolerance +/- | Cross Section | Tolerance +/- | I.D. MM | Section MM | Volume Cu. Inch | Nominal I.D. | Nominal O.D. | Nominal Width |

|---|---|---|---|---|---|---|---|---|---|---|

| -001 | 0.029 | 0.006 | 0.040 | 0.003 | 0,74 | 1,02 | 0.0003 | 1/32 | 3/32 | 1/32 |

| -002 | 0.042 | 0.006 | 0.050 | 0.003 | 1,07 | 1,27 | 0.0006 | 3/64 | 9/64 | 3/64 |

| -003 | 0.056 | 0.006 | 0.060 | 0.003 | 1,42 | 1,53 | 0.0010 | 1/16 | 3/16 | 1/16 |

| -004 | 0.070 | 0.006 | 0.070 | 0.003 | 1,78 | 1,78 | 0.0017 | 5/64 | 13/16 | 1/16 |

| -005 | 0.101 | 0.006 | 0.070 | 0.003 | 2,57 | 1,78 | 0.0021 | 3/32 | 7/32 | 1/16 |

| -006 | 0.114 | 0.006 | 0.070 | 0.003 | 2,90 | 1,78 | 0.0022 | 1/8 | 1/4 | 1/16 |

| -007 | 0.145 | 0.006 | 0.070 | 0.003 | 3,69 | 1,78 | 0.0026 | 5/32 | 9/32 | 1/16 |

| -008 | 0.176 | 0.006 | 0.070 | 0.003 | 4,47 | 1,78 | 0.0030 | 3/16 | 5/16 | 1/16 |

| -009 | 0.208 | 0.006 | 0.070 | 0.003 | 5,28 | 1,78 | 0.0034 | 7/32 | 11/32 | 1/16 |

| -010 | 0.239 | 0.007 | 0.070 | 0.003 | 6,07 | 1,78 | 0.0037 | 1/4 | 3/8 | 1/16 |

| -011 | 0.239 | 0.007 | 0.070 | 0.003 | 7,66 | 1,78 | 0.0045 | 5/16 | 7/16 | 1/16 |

| -012 | 0.301 | 0.007 | 0.070 | 0.003 | 9,25 | 1,78 | 0.0052 | 3/8 | 1/2 | 1/16 |

| -013 | 0.426 | 0.007 | 0.070 | 0.003 | 10,82 | 1,78 | 0.0060 | 7/16 | 9/16 | 1/16 |

| -014 | 0.489 | 0.007 | 0.070 | 0.003 | 12,42 | 1,78 | 0.0068 | 1/2 | 5/8 | 1/16 |

| -015 | 0.551 | 0.007 | 0.070 | 0.003 | 14,00 | 1,78 | 0.0075 | 9/16 | 11/16 | 1/16 |

| -016 | 0.614 | 0.009 | 0.070 | 0.003 | 15,60 | 1,78 | 0.0083 | 5/8 | 3/4 | 1/16 |

| -017 | 0.676 | 0.009 | 0.070 | 0.003 | 17,16 | 1,78 | 0.0090 | 11/16 | 13/16 | 1/16 |

| -018 | 0.739 | 0.009 | 0.070 | 0.003 | 18,77 | 1,78 | 0.0098 | 3/4 | 7/8 | 1/16 |

| -019 | 0.801 | 0.009 | 0.070 | 0.003 | 20,35 | 1,78 | 0.0105 | 13/16 | 15/16 | 1/16 |

| -020 | 0.864 | 0.009 | 0.070 | 0.003 | 21,95 | 1,78 | 0.0113 | 7/8 | 1 | 1/16 |

| -021 | 0.926 | 0.009 | 0.070 | 0.003 | 23,52 | 1,78 | 0.0120 | 15/16 | 1 1/16 | 1/16 |

| -022 | 0.989 | 0.010 | 0.070 | 0.003 | 25,12 | 1,78 | 0.0128 | 1 | 1 1/8 | 1/16 |

| -023 | 1.051 | 0.010 | 0.070 | 0.003 | 26,70 | 1,78 | 0.0136 | 1 1/16 | 1 3/16 | 1/16 |

| -024 | 1.114 | 0.010 | 0.070 | 0.003 | 28,30 | 1,78 | 0.0143 | 1 1/8 | 1 1/4 | 1/16 |

| -025 | 1.176 | 0.011 | 0.070 | 0.003 | 29,87 | 1,78 | 0.0151 | 1 3/16 | 1 5/16 | 1/16 |

| -026 | 1.239 | 0.011 | 0.070 | 0.003 | 31,47 | 1,78 | 0.0158 | 1 1/4 | 1 3/8 | 1/16 |

| -027 | 1.301 | 0.011 | 0.070 | 0.003 | 33,05 | 1,78 | 0.0166 | 1 5/16 | 1 7/16 | 1/16 |

| -028 | 1.364 | 0.013 | 0.070 | 0.003 | 34,65 | 1,78 | 0.0173 | 1 3/8 | 1 1/2 | 1/16 |

| -029 | 1.489 | 0.013 | 0.070 | 0.003 | 37,82 | 1,78 | 0.0188 | 1 1/2 | 1 5/8 | 1/16 |

| -030 | 1.614 | 0.013 | 0.070 | 0.003 | 41,06 | 1,78 | 0.0204 | 1 5/8 | 1 3/4 | 1/16 |

| -031 | 1.739 | 0.015 | 0.070 | 0.003 | 44,17 | 1,78 | 0.0219 | 1 3/4 | 1 7/8 | 1/16 |

| -032 | 1.864 | 0.015 | 0.070 | 0.003 | 47,37 | 1,78 | 0.0234 | 1 7/8 | 2 | 1/16 |

| -033 | 1.989 | 0.018 | 0.070 | 0.003 | 50,52 | 1,78 | 0.0249 | 2 | 2 1/8 | 1/16 |

| -034 | 2.114 | 0.018 | 0.070 | 0.003 | 53,67 | 1,78 | 0.0264 | 2 1/8 | 2 1/4 | 1/16 |

| -035 | 2.239 | 0.018 | 0.070 | 0.003 | 56,87 | 1,78 | 0.0279 | 2 1/4 | 2 3/8 | 1/16 |

| -036 | 2.364 | 0.018 | 0.070 | 0.003 | 60,04 | 1,78 | 0.0294 | 2 3/8 | 2 1/2 | 1/16 |

| -037 | 2.489 | 0.018 | 0.070 | 0.003 | 63,22 | 1,78 | 0.0309 | 2 1/2 | 2 5/8 | 1/16 |

| -038 | 2.614 | 0.020 | 0.070 | 0.003 | 66,50 | 1,78 | 0.0324 | 2 5/8 | 2 3/4 | 1/16 |

| -039 | 2.739 | 0.020 | 0.070 | 0.003 | 69,57 | 1,78 | 0.0340 | 2 3/4 | 2 7/8 | 1/16 |

| -040 | 2.864 | 0.020 | 0.070 | 0.003 | 72,76 | 1,78 | 0.0355 | 2 7/8 | 3 | 1/16 |

| -041 | 2.989 | 0.024 | 0.070 | 0.003 | 75,94 | 1,78 | 0.0370 | 3 | 3 1/4 | 1/16 |

| -042 | 3.239 | 0.024 | 0.070 | 0.003 | 82,28 | 1,78 | 0.0400 | 3 1/4 | 3 1/2 | 1/16 |

| -043 | 3.489 | 0.024 | 0.070 | 0.003 | 88,64 | 1,78 | 0.0430 | 3 1/2 | 3 3/4 | 1/16 |

| -044 | 3.739 | 0.027 | 0.070 | 0.003 | 95,12 | 1,78 | 0.0460 | 3 3/4 | 3 7/8 | 1/16 |

| -045 | 3.989 | 0.027 | 0.070 | 0.003 | 101,34 | 1,78 | 0.0491 | 4 | 4 1/8 | 1/16 |

| -046 | 4.239 | 0.030 | 0.070 | 0.003 | 107,84 | 1,78 | 0.0521 | 4 1/4 | 4 3/8 | 1/16 |

| -047 | 4.489 | 0.030 | 0.070 | 0.003 | 114,20 | 1,78 | 0.0551 | 4 1/2 | 4 5/8 | 1/16 |

| -048 | 4.739 | 0.030 | 0.070 | 0.003 | 120,56 | 1,78 | 0.0581 | 4 3/4 | 4 7/8 | 1/16 |

| -049 | 4.989 | 0.037 | 0.070 | 0.003 | 126,92 | 1,78 | 0.0612 | 5 | 5 1/4 | 1/16 |

| -050 | 0.049 | 0.037 | 0.070 | 0.003 | 133,28 | 1,78 | 0.0643 | 1/16 | 5 3/8 | 1/16 |

| -102 | 0.081 | 0.006 | 0.103 | 0.003 | 1,24 | 2,62 | 0.0040 | 3/32 | 9/32 | 3/32 |

| -103 | 0.112 | 0.006 | 0.103 | 0.003 | 2,06 | 2,62 | 0.0048 | 2,84 | 5/16 | 3/32 |

| -104 | 0.143 | 0.006 | 0.103 | 0.003 | 3,63 | 2,62 | 0.0064 | 5/32 | 11/32 | 3/32 |

| -105 | 0.174 | 0.006 | 0.103 | 0.003 | 4,42 | 2,62 | 0.0072 | 3/16 | 3/8 | 3/32 |

| -106 | 0.206 | 0.006 | 0.103 | 0.003 | 5,23 | 2,62 | 0.0080 | 7/32 | 13/32 | 3/32 |

| -107 | 0.237 | 0.007 | 0.103 | 0.003 | 6,02 | 2,62 | 0.0088 | 1/4 | 7/16 | 3/32 |

| -108 | 0.299 | 0.007 | 0.103 | 0.003 | 7,60 | 2,62 | 0.0105 | 5/16 | 1/2 | 3/32 |

| -109 | 0.362 | 0.007 | 0.103 | 0.003 | 9,19 | 2,62 | 0.0122 | 3/8 | 9/16 | 3/32 |

| -110 | 0.424 | 0.007 | 0.103 | 0.003 | 10,78 | 2,62 | 0.0138 | 7/16 | 5/8 | 3/32 |

| -111 | 0.487 | 0.007 | 0.103 | 0.003 | 12,37 | 2,62 | 0.0154 | 1/2 | 11/16 | 3/32 |

| -112 | 0.549 | 0.007 | 0.103 | 0.003 | 13,95 | 2,62 | 0.0171 | 9/16 | 3/4 | 3/32 |

| -113 | 0.612 | 0.007 | 0.103 | 0.003 | 15,54 | 2,62 | 0.0187 | 5/8 | 13/16 | 3/32 |

| -114 | 0.674 | 0.009 | 0.103 | 0.003 | 17,13 | 2,62 | 0.0203 | 11/16 | 7/8 | 3/32 |

| -115 | 0.737 | 0.009 | 0.103 | 0.003 | 18,72 | 2,62 | 0.0220 | 3/4 | 15/16 | 3/32 |

| -116 | 0.799 | 0.009 | 0.103 | 0.003 | 20,29 | 2,62 | 0.0236 | 13/16 | 1 | 3/32 |

| -117 | 0.862 | 0.010 | 0.103 | 0.003 | 21,90 | 2,62 | 0.0253 | 7/8 | 1 1/16 | 3/32 |

| -118 | 0.924 | 0.010 | 0.103 | 0.003 | 23,47 | 2,62 | 0.0269 | 15/16 | 1 1/8 | 3/32 |

| -119 | 0.987 | 0.010 | 0.103 | 0.003 | 25,07 | 2,62 | 0.0285 | 1 | 1 3/16 | 3/32 |

| -120 | 1.049 | 0.010 | 0.103 | 0.003 | 26,65 | 2,62 | 0.0302 | 1 1/16 | 1 1/4 | 3/32 |

| -121 | 1.112 | 0.010 | 0.103 | 0.003 | 28,25 | 2,62 | 0.0318 | 1 1/8 | 1 5/16 | 3/32 |

| -122 | 1.174 | 0.010 | 0.103 | 0.003 | 29,83 | 2,62 | 0.0334 | 1 3/16 | 1 3/8 | 3/32 |

| -123 | 1.237 | 0.012 | 0.103 | 0.003 | 31,42 | 2,62 | 0.0351 | 1 1/4 | 1 7/16 | 3/32 |

| -124 | 1.299 | 0.012 | 0.103 | 0.003 | 33,05 | 2,62 | 0.0367 | 1 5/16 | 1 1/2 | 3/32 |

| -125 | 1.362 | 0.012 | 0.103 | 0.003 | 34,60 | 2,62 | 0.0383 | 1 3/8 | 1 9/16 | 3/32 |

| -126 | 1.424 | 0.012 | 0.103 | 0.003 | 36,17 | 2,62 | 0.0400 | 1 7/16 | 1 5/8 | 3/32 |

| -127 | 1.487 | 0.012 | 0.103 | 0.003 | 37,77 | 2,62 | 0.0416 | 1 1/2 | 1 11/16 | 3/32 |

| -128 | 1.549 | 0.012 | 0.103 | 0.003 | 39,35 | 2,62 | 0.0432 | 1 9/16 | 1 3/4 | 3/32 |

| -129 | 1.612 | 0.015 | 0.103 | 0.003 | 40,95 | 2,62 | 0.0449 | 1 5/8 | 1 13/16 | 3/32 |

| -130 | 1.674 | 0.015 | 0.103 | 0.003 | 42,52 | 2,62 | 0.0465 | 1 11/16 | 1 7/8 | 3/32 |

| -131 | 1.737 | 0.015 | 0.103 | 0.003 | 44,12 | 2,62 | 0.0482 | 1 3/4 | 1 15/16 | 3/32 |

| -132 | 1.799 | 0.015 | 0.103 | 0.003 | 45,70 | 2,62 | 0.0498 | 1 13/16 | 2 | 3/32 |

| -133 | 1.862 | 0.015 | 0.103 | 0.003 | 47,30 | 2,62 | 0.0514 | 1 7/8 | 2 1/16 | 3/32 |

| -134 | 1.925 | 0.015 | 0.103 | 0.003 | 48,90 | 2,62 | 0.0531 | 1 15/16 | 2 1/8 | 3/32 |

| -135 | 1.987 | 0.017 | 0.103 | 0.003 | 50,47 | 2,62 | 0.0547 | 2 | 2 3/16 | 3/32 |

| -136 | 2.050 | 0.017 | 0.103 | 0.003 | 52,07 | 2,62 | 0.0564 | 2 1/16 | 2 1/4 | 3/32 |

| -137 | 2.112 | 0.017 | 0.103 | 0.003 | 53,65 | 2,62 | 0.0580 | 2 1/8 | 2 5/16 | 3/32 |

| -138 | 2.175 | 0.017 | 0.103 | 0.003 | 55,25 | 2,62 | 0.0596 | 2 3/16 | 2 3/8 | 3/32 |

| -139 | 2.237 | 0.017 | 0.103 | 0.003 | 56,82 | 2,62 | 0.0612 | 2 1/4 | 2 7/16 | 3/32 |

| -140 | 2.300 | 0.017 | 0.103 | 0.003 | 58,42 | 2,62 | 0.0629 | 2 5/16 | 2 1/2 | 3/32 |

| -141 | 2.362 | 0.020 | 0.103 | 0.003 | 60,09 | 2,62 | 0.0645 | 2 3/8 | 2 9/16 | 3/32 |

| -142 | 2.425 | 0.020 | 0.103 | 0.003 | 61,60 | 2,62 | 0.0662 | 2 7/16 | 2 5/8 | 3/32 |

| -143 | 2.487 | 0.020 | 0.103 | 0.003 | 63,17 | 2,62 | 0.0678 | 2 1/2 | 2 11/16 | 3/32 |

| -144 | 2.550 | 0.020 | 0.103 | 0.003 | 64,77 | 2,62 | 0.0694 | 2 9/16 | 2 3/4 | 3/32 |

| -145 | 2.612 | 0.020 | 0.103 | 0.003 | 66,35 | 2,62 | 0.0711 | 2 5/8 | 2 13/16 | 3/32 |

| -146 | 2.675 | 0.020 | 0.103 | 0.003 | 67,95 | 2,62 | 0.0727 | 2 11/16 | 2 7/8 | 3/32 |

| -147 | 2.737 | 0.022 | 0.103 | 0.003 | 69,52 | 2,62 | 0.0743 | 2 3/4 | 2 15/16 | 3/32 |

| -148 | 2.800 | 0.022 | 0.103 | 0.003 | 71,12 | 2,62 | 0.0760 | 2 7/8 | 3 | 3/32 |

| -149 | 2.862 | 0.022 | 0.103 | 0.003 | 72,70 | 2,62 | 0.0776 | 2 15/16 | 3 1/8 | 3/32 |

| -150 | 2.987 | 0.022 | 0.103 | 0.003 | 75,88 | 2,62 | 0.0809 | 3 | 3 3/16 | 3/32 |

| -151 | 3.237 | 0.024 | 0.103 | 0.003 | 82,22 | 2,62 | 0.0874 | 3 1/4 | 3 7/16 | 3/32 |

| -152 | 3.487 | 0.024 | 0.103 | 0.003 | 88,58 | 2,62 | 0.0940 | 3 1/2 | 3 11/16 | 3/32 |

| -153 | 3.737 | 0.024 | 0.103 | 0.003 | 94,93 | 2,62 | 0.1005 | 3 3/4 | 3 15/16 | 3/32 |

| -154 | 3.987 | 0.028 | 0.103 | 0.003 | 101,28 | 2,62 | 0.1071 | 4 | 4 3/16 | 3/32 |

| -155 | 4.237 | 0.028 | 0.103 | 0.003 | 107,63 | 2,62 | 0.1136 | 4 1/4 | 4 7/16 | 3/32 |

| -156 | 4.487 | 0.030 | 0.103 | 0.003 | 113,98 | 2,62 | 0.1202 | 4 1/2 | 4 11/16 | 3/32 |

| -157 | 4.737 | 0.030 | 0.103 | 0.003 | 120,33 | 2,62 | 0.1267 | 4 3/4 | 4 15/16 | 3/32 |

| -158 | 4.987 | 0.035 | 0.103 | 0.003 | 126,67 | 2,62 | 0.1332 | 5 | 5 3/16 | 3/32 |

| -159 | 5.237 | 0.035 | 0.103 | 0.003 | 133,23 | 2,62 | 0.1398 | 5 1/4 | 5 7/16 | 3/32 |

| -160 | 5.487 | 0.035 | 0.103 | 0.003 | 139,38 | 2,62 | 0.1463 | 5 1/2 | 5 11/16 | 3/32 |

| -161 | 5.737 | 0.035 | 0.103 | 0.003 | 145,73 | 2,62 | 0.1529 | 5 3/4 | 5 15/16 | 3/32 |

| -162 | 5.987 | 0.035 | 0.103 | 0.003 | 152,07 | 2,62 | 0.1594 | 6 | 6 3/16 | 3/32 |

| -163 | 6.237 | 0.040 | 0.103 | 0.003 | 158,43 | 2,62 | 0.1660 | 6 1/4 | 6 7/16 | 3/32 |

| -164 | 6.487 | 0.040 | 0.103 | 0.003 | 164,78 | 2,62 | 0.1726 | 6 1/2 | 6 11/16 | 3/32 |

| -165 | 6.737 | 0.040 | 0.103 | 0.003 | 171,13 | 2,62 | 0.1791 | 6 3/4 | 6 15/16 | 3/32 |

| -166 | 6.987 | 0.040 | 0.103 | 0.003 | 177,48 | 2,62 | 0.1856 | 7 | 7 3/16 | 3/32 |

| -167 | 7.237 | 0.045 | 0.103 | 0.003 | 183,83 | 2,62 | 0.1921 | 7 1/4 | 7 7/16 | 3/32 |

| -168 | 7.487 | 0.045 | 0.103 | 0.003 | 190,18 | 2,62 | 0.1986 | 7 1/2 | 7 11/16 | 3/32 |

| -169 | 7.737 | 0.045 | 0.103 | 0.003 | 196,53 | 2,62 | 0.2052 | 7 3/4 | 7 15/16 | 3/32 |

| -170 | 7.987 | 0.045 | 0.103 | 0.003 | 202,88 | 2,62 | 0.2117 | 8 | 8 3/16 | 3/32 |

| -171 | 8.237 | 0.050 | 0.103 | 0.003 | 209,23 | 2,62 | 0.2182 | 8 1/4 | 8 7/16 | 3/32 |

| -172 | 8.487 | 0.050 | 0.103 | 0.003 | 215,58 | 2,62 | 0.2247 | 8 1/2 | 8 11/16 | 3/32 |

| -173 | 8.737 | 0.050 | 0.103 | 0.003 | 221,93 | 2,62 | 0.2313 | 8 3/4 | 8 15/16 | 3/32 |

| -174 | 8.987 | 0.050 | 0.103 | 0.003 | 228,28 | 2,62 | 0.2378 | 9 | 9 3/16 | 3/32 |

| -175 | 9.237 | 0.055 | 0.103 | 0.003 | 234,63 | 2,62 | 0.2443 | 9 1/4 | 9 7/16 | 3/32 |

| -176 | 9.487 | 0.055 | 0.103 | 0.003 | 240,98 | 2,62 | 0.2508 | 9 1/2 | 9 11/16 | 3/32 |

| -177 | 9.737 | 0.055 | 0.103 | 0.003 | 247,33 | 2,62 | 0.2574 | 9 3/4 | 9 15/16 | 3/32 |

| -178 | 0.171 | 0.006 | 0.139 | 0.004 | 4,34 | 3,53 | 0.0148 | 3/16 | 7/16 | 1/8 |

| -201 | 0.234 | 0.007 | 0.139 | 0.004 | 5,94 | 3,53 | 0.0178 | 1/4 | 1/2 | 1/8 |

| -202 | 0.296 | 0.007 | 0.139 | 0.004 | 7,52 | 3,53 | 0.0207 | 5/16 | 9/16 | 1/8 |

| -203 | 0.359 | 0.007 | 0.139 | 0.004 | 9,12 | 3,53 | 0.0237 | 3/8 | 5/8 | 1/8 |

| -204 | 0.421 | 0.007 | 0.139 | 0.004 | 10,69 | 3,53 | 0.0267 | 7/16 | 11/16 | 1/8 |

| -205 | 0.484 | 0.007 | 0.139 | 0.004 | 12,29 | 3,53 | 0.0297 | 1/2 | 3/4 | 1/8 |

| -206 | 0.546 | 0.007 | 0.139 | 0.004 | 13,87 | 3,53 | 0.0327 | 9/16 | 13/16 | 1/8 |

| -207 | 0.609 | 0.009 | 0.139 | 0.004 | 15,47 | 3,53 | 0.0357 | 5/8 | 7/8 | 1/8 |

| -208 | 0.671 | 0.009 | 0.139 | 0.004 | 17,04 | 3,53 | 0.0386 | 11/16 | 15/16 | 1/8 |

| -209 | 0.734 | 0.010 | 0.139 | 0.004 | 18,64 | 3,53 | 0.0416 | 3/4 | 1 | 1/8 |

| -210 | 0.796 | 0.010 | 0.139 | 0.004 | 20,22 | 3,53 | 0.0446 | 13/16 | 1 1/16 | 1/8 |

| -211 | 0.859 | 0.010 | 0.139 | 0.004 | 21,82 | 3,53 | 0.0476 | 7/8 | 1 1/8 | 1/8 |

| -212 | 0.921 | 0.010 | 0.139 | 0.004 | 23,43 | 3,53 | 0.0505 | 15/16 | 1 3/16 | 1/8 |

| -213 | 0.984 | 0.010 | 0.139 | 0.004 | 25,03 | 3,53 | 0.0535 | 1 | 1 1/4 | 1/8 |

| -214 | 1.046 | 0.010 | 0.139 | 0.004 | 26,57 | 3,53 | 0.0565 | 1 1/16 | 1 5/16 | 1/8 |

| -215 | 1.109 | 0.012 | 0.139 | 0.004 | 28,17 | 3,53 | 0.0595 | 1 1/8 | 1 3/8 | 1/8 |

| -216 | 1.171 | 0.012 | 0.139 | 0.004 | 29,75 | 3,53 | 0.0624 | 1 3/16 | 1 7/16 | 1/8 |

| -217 | 1.234 | 0.012 | 0.139 | 0.004 | 31,34 | 3,53 | 0.0656 | 1 1/4 | 1 1/2 | 1/8 |

| -218 | 1.296 | 0.012 | 0.139 | 0.004 | 32,93 | 3,53 | 0.0684 | 1 5/16 | 1 9/16 | 1/8 |

| -219 | 1.359 | 0.012 | 0.139 | 0.004 | 34,52 | 3,53 | 0.0714 | 1 3/8 | 1 5/8 | 1/8 |

| -220 | 1.421 | 0.012 | 0.139 | 0.004 | 36,15 | 3,53 | 0.0744 | 1 7/16 | 1 11/16 | 1/8 |

| -221 | 1.484 | 0.012 | 0.139 | 0.004 | 37,75 | 3,53 | 0.0774 | 1 1/2 | 1 3/4 | 1/8 |

| -222 | 1.609 | 0.015 | 0.139 | 0.004 | 40,87 | 3,53 | 0.0833 | 1 5/8 | 1 7/8 | 1/8 |

| -223 | 1.734 | 0.015 | 0.139 | 0.004 | 44,05 | 3,53 | 0.0893 | 1 3/4 | 2 | 1/8 |

| -224 | 1.859 | 0.015 | 0.139 | 0.004 | 47,23 | 3,53 | 0.0952 | 1 7/8 | 2 1/8 | 1/8 |

| -225 | 1.984 | 0.018 | 0.139 | 0.004 | 50,47 | 3,53 | 0.1012 | 2 | 2 1/4 | 1/8 |

| -226 | 2.109 | 0.018 | 0.139 | 0.004 | 53,57 | 3,53 | 0.1072 | 2 1/8 | 2 3/8 | 1/8 |

| -227 | 2.234 | 0.018 | 0.139 | 0.004 | 56,75 | 3,53 | 0.1131 | 2 1/4 | 2 1/2 | 1/8 |

| -228 | 2.359 | 0.020 | 0.139 | 0.004 | 59,92 | 3,53 | 0.1191 | 2 3/8 | 2 5/8 | 1/8 |

| -229 | 2.484 | 0.020 | 0.139 | 0.004 | 63,19 | 3,53 | 0.1250 | 2 1/2 | 2 3/4 | 1/8 |

| -230 | 2.609 | 0.020 | 0.139 | 0.004 | 66,27 | 3,53 | 0.1310 | 2 5/8 | 2 7/8 | 1/8 |

| -231 | 2.734 | 0.024 | 0.139 | 0.004 | 69,44 | 3,53 | 0.1370 | 2 3/4 | 3 | 1/8 |

| -232 | 2.859 | 0.024 | 0.139 | 0.004 | 72,62 | 3,53 | 0.1429 | 2 7/8 | 3 1/8 | 1/8 |

| -233 | 2.984 | 0.024 | 0.139 | 0.004 | 75,91 | 3,53 | 0.1489 | 3 | 3 1/4 | 1/8 |

| -234 | 3.109 | 0.024 | 0.139 | 0.004 | 78,97 | 3,53 | 0.1548 | 3 1/8 | 3 3/8 | 1/8 |

| -235 | 3.234 | 0.024 | 0.139 | 0.004 | 82,14 | 3,53 | 0.1608 | 3 1/4 | 3 1/2 | 1/8 |

| -236 | 3.359 | 0.024 | 0.139 | 0.004 | 85,32 | 3,53 | 0.1668 | 3 3/8 | 3 5/8 | 1/8 |

| -237 | 3.484 | 0.024 | 0.139 | 0.004 | 88,63 | 3,53 | 0.1727 | 3 1/2 | 3 3/4 | 1/8 |

| -238 | 3.609 | 0.028 | 0.139 | 0.004 | 91,67 | 3,53 | 0.1787 | 3 5/8 | 3 7/8 | 1/8 |

| -239 | 3.734 | 0.028 | 0.139 | 0.004 | 94,84 | 3,53 | 0.1846 | 3 3/4 | 4 | 1/8 |

| -240 | 3.859 | 0.028 | 0.139 | 0.004 | 98,02 | 3,53 | 0.1906 | 3 7/8 | 4 1/8 | 1/8 |

| -241 | 3.984 | 0.028 | 0.139 | 0.004 | 101,35 | 3,53 | 0.1966 | 4 | 4 1/4 | 1/8 |

| -242 | 4.109 | 0.028 | 0.139 | 0.004 | 104,37 | 3,53 | 0.2025 | 4 1/8 | 4 3/8 | 1/8 |

| -243 | 4.234 | 0.030 | 0.139 | 0.004 | 107,54 | 3,53 | 0.2085 | 4 1/4 | 4 1/2 | 1/8 |

| -244 | 4.359 | 0.030 | 0.139 | 0.004 | 110,72 | 3,53 | 0.2144 | 4 3/8 | 4 5/8 | 1/8 |

| -245 | 4.484 | 0.030 | 0.139 | 0.004 | 114,07 | 3,53 | 0.2204 | 4 1/2 | 4 3/4 | 1/8 |

| -246 | 4.609 | 0.030 | 0.139 | 0.004 | 117,07 | 3,53 | 0.2264 | 4 5/8 | 4 7/8 | 1/8 |

| -247 | 4.734 | 0.030 | 0.139 | 0.004 | 120,24 | 3,53 | 0.2323 | 4 3/4 | 5 | 1/8 |

| -248 | 4.859 | 0.035 | 0.139 | 0.004 | 123,42 | 3,53 | 0.2383 | 4 7/8 | 5 1/8 | 1/8 |

| -249 | 4.984 | 0.035 | 0.139 | 0.004 | 126,79 | 3,53 | 0.2442 | 5 | 5 1/4 | 1/8 |

| -250 | 5.109 | 0.035 | 0.139 | 0.004 | 129,77 | 3,53 | 0.2502 | 5 1/8 | 5 3/8 | 1/8 |

| -251 | 5.234 | 0.035 | 0.139 | 0.004 | 133,15 | 3,53 | 0.2561 | 5 1/4 | 5 1/2 | 1/8 |

| -252 | 5.359 | 0.035 | 0.139 | 0.004 | 136,33 | 3,53 | 0.2621 | 5 3/8 | 5 5/8 | 1/8 |

| -253 | 5.484 | 0.035 | 0.139 | 0.004 | 139,51 | 3,53 | 0.2681 | 5 1/2 | 5 3/4 | 1/8 |

| -254 | 5.609 | 0.035 | 0.139 | 0.004 | 142,69 | 3,53 | 0.2740 | 5 5/8 | 5 7/8 | 1/8 |

| -255 | 5.734 | 0.035 | 0.139 | 0.004 | 145,87 | 3,53 | 0.2800 | 5 3/4 | 6 | 1/8 |

| -256 | 5.859 | 0.035 | 0.139 | 0.004 | 149,05 | 3,53 | 0.2859 | 5 7/8 | 6 1/8 | 1/8 |

| -257 | 5.984 | 0.035 | 0.139 | 0.004 | 152,23 | 3,53 | 0.2919 | 6 | 6 1/4 | 1/8 |

| -258 | 6.234 | 0.040 | 0.139 | 0.004 | 158,59 | 3,53 | 0.3038 | 6 1/4 | 6 1/2 | 1/8 |

| -259 | 6.484 | 0.040 | 0.139 | 0.004 | 164,95 | 3,53 | 0.3157 | 6 1/2 | 6 3/4 | 1/8 |

| -260 | 6.734 | 0.040 | 0.139 | 0.004 | 171,31 | 3,53 | 0.3276 | 6 3/4 | 7 | 1/8 |

| -261 | 6.984 | 0.040 | 0.139 | 0.004 | 177,67 | 3,53 | 0.3396 | 7 | 7 1/4 | 1/8 |

| -262 | 7.234 | 0.045 | 0.139 | 0.004 | 184,03 | 3,53 | 0.3515 | 7 1/4 | 7 1/2 | 1/8 |

| -263 | 7.484 | 0.045 | 0.139 | 0.004 | 190,39 | 3,53 | 0.3634 | 7 1/2 | 7 3/4 | 1/8 |

| -264 | 7.734 | 0.045 | 0.139 | 0.004 | 196,75 | 3,53 | 0.3753 | 7 3/4 | 8 | 1/8 |

| -265 | 7.984 | 0.045 | 0.139 | 0.004 | 203,11 | 3,53 | 0.3872 | 8 | 8 1/4 | 1/8 |

| -266 | 8.234 | 0.045 | 0.139 | 0.004 | 209,47 | 3,53 | 0.3992 | 8 1/4 | 8 1/2 | 1/8 |

| -267 | 8.484 | 0.045 | 0.139 | 0.004 | 215,83 | 3,53 | 0.4117 | 8 1/2 | 8 3/4 | 1/8 |

| -268 | 8.734 | 0.050 | 0.139 | 0.004 | 222,19 | 3,53 | 0.4230 | 8 3/4 | 9 | 1/8 |

| -269 | 8.984 | 0.050 | 0.139 | 0.004 | 228,55 | 3,53 | 0.4349 | 9 | 9 1/4 | 1/8 |

| -270 | 9.234 | 0.050 | 0.139 | 0.004 | 234,91 | 3,53 | 0.4468 | 9 1/4 | 9 1/2 | 1/8 |

| -271 | 9.484 | 0.050 | 0.139 | 0.004 | 241,27 | 3,53 | 0.4588 | 9 1/2 | 9 3/4 | 1/8 |

| -272 | 9.734 | 0.055 | 0.139 | 0.004 | 247,63 | 3,53 | 0.4707 | 9 3/4 | 10 | 1/8 |

| -273 | 9.984 | 0.055 | 0.139 | 0.004 | 253,99 | 3,53 | 0.4826 | 10 | 10 1/4 | 1/8 |

| -274 | 10.484 | 0.055 | 0.139 | 0.004 | 266,71 | 3,53 | 0.5064 | 10 1/2 | 10 3/4 | 1/8 |

| -275 | 10.984 | 0.055 | 0.139 | 0.004 | 279,43 | 3,53 | 0.5303 | 11 | 11 1/4 | 1/8 |

| -276 | 11.484 | 0.055 | 0.139 | 0.004 | 292,15 | 3,53 | 0.5541 | 11 1/2 | 11 3/4 | 1/8 |

| -277 | 11.984 | 0.065 | 0.139 | 0.004 | 304,87 | 3,53 | 0.5779 | 12 | 12 1/4 | 1/8 |

| -278 | 12.984 | 0.065 | 0.139 | 0.004 | 330,31 | 3,53 | 0.6256 | 13 | 13 1/4 | 1/8 |

| -279 | 13.984 | 0.065 | 0.139 | 0.004 | 355,75 | 3,53 | 0.6733 | 14 | 14 1/4 | 1/8 |

| -280 | 14.984 | 0.065 | 0.139 | 0.004 | 381,19 | 3,53 | 0.7210 | 15 | 15 1/4 | 1/8 |

| -281 | 15.955 | 0.065 | 0.139 | 0.004 | 405,90 | 3,53 | 0.7676 | 16 | 16 1/4 | 1/8 |

| -282 | 16.955 | 0.075 | 0.139 | 0.004 | 431,34 | 3,53 | 0.8155 | 17 | 17 1/4 | 1/8 |

| -283 | 17.955 | 0.080 | 0.139 | 0.004 | 456,78 | 3,53 | 0.8627 | 18 | 18 1/4 | 1/8 |

| -284 | 0.412 | 0.085 | 0.139 | 0.004 | 10,48 | 3,53 | 0.0677 | 7/16 | 13/16 | 3/16 |

| -309 | 0.475 | 0.007 | 0.21 | 0.004 | 12,08 | 3,53 | 0.0745 | 1/2 | 7/8 | 3/16 |

| -310 | 0.537 | 0.007 | 0.21 | 0.004 | 13,66 | 3,53 | 0.0813 | 9/16 | 15/16 | 3/16 |

| -311 | 0.600 | 0.009 | 0.21 | 0.004 | 15,26 | 3,53 | 0.0881 | 5/8 | 1 | 3/16 |

| -312 | 0.662 | 0.009 | 0.21 | 0.004 | 16,84 | 3,53 | 0.0949 | 11/16 | 1 1/16 | 3/16 |

| -313 | 0.725 | 0.009 | 0.21 | 0.004 | 18,44 | 3,53 | 0.1017 | 3/4 | 1 1/8 | 3/16 |

| -314 | 0.787 | 0.009 | 0.21 | 0.004 | 20,02 | 3,53 | 0.1085 | 13/16 | 1 3/16 | 3/16 |

| -315 | 0.850 | 0.009 | 0.21 | 0.004 | 21,62 | 3,53 | 0.1153 | 7/8 | 1 1/4 | 3/16 |

| -316 | 0.912 | 0.009 | 0.21 | 0.004 | 23,20 | 3,53 | 0.1221 | 15/16 | 1 5/16 | 3/16 |

| -317 | 0.975 | 0.010 | 0.21 | 0.004 | 24,80 | 3,53 | 0.1289 | 1 | 1 3/8 | 3/16 |

| -318 | 1.037 | 0.010 | 0.21 | 0.004 | 26,38 | 3,53 | 0.1357 | 1 1/16 | 1 7/16 | 3/16 |

| -319 | 1.100 | 0.010 | 0.21 | 0.004 | 27,98 | 3,53 | 0.1425 | 1 1/8 | 1 1/2 | 3/16 |

| -320 | 1.162 | 0.011 | 0.21 | 0.004 | 29,56 | 3,53 | 0.1493 | 1 3/16 | 1 9/16 | 3/16 |

| -321 | 1.225 | 0.011 | 0.21 | 0.004 | 31,16 | 3,53 | 0.1561 | 1 1/4 | 1 5/8 | 3/16 |

| -322 | 1.287 | 0.011 | 0.21 | 0.004 | 32,74 | 3,53 | 0.1629 | 1 5/16 | 1 11/16 | 3/16 |

| -323 | 1.350 | 0.011 | 0.21 | 0.004 | 34,34 | 3,53 | 0.1697 | 1 3/8 | 1 3/4 | 3/16 |

| -324 | 1.475 | 0.011 | 0.21 | 0.004 | 37,52 | 3,53 | 0.1833 | 1 1/2 | 1 7/8 | 3/16 |

| -325 | 1.600 | 0.015 | 0.21 | 0.004 | 47,70 | 3,53 | 0.1970 | 1 5/8 | 2 | 3/16 |

| -326 | 1.725 | 0.015 | 0.21 | 0.004 | 43,88 | 3,53 | 0.2106 | 1 3/4 | 2 1/8 | 3/16 |

| -327 | 1.850 | 0.015 | 0.21 | 0.004 | 47,06 | 3,53 | 0.2242 | 1 7/8 | 2 1/4 | 3/16 |

| -328 | 1.975 | 0.015 | 0.21 | 0.004 | 50,24 | 3,53 | 0.2378 | 2 | 2 3/8 | 3/16 |

| -329 | 2.100 | 0.018 | 0.21 | 0.004 | 53,42 | 3,53 | 0.2514 | 2 1/8 | 2 1/2 | 3/16 |

| -330 | 2.225 | 0.018 | 0.21 | 0.004 | 56,60 | 3,53 | 0.2650 | 2 1/4 | 2 5/8 | 3/16 |

| -331 | 2.350 | 0.018 | 0.21 | 0.004 | 59,78 | 3,53 | 0.2786 | 2 3/8 | 2 3/4 | 3/16 |

| -332 | 2.475 | 0.018 | 0.21 | 0.004 | 62,96 | 3,53 | 0.2922 | 2 1/2 | 2 7/8 | 3/16 |

| -333 | 2.600 | 0.020 | 0.21 | 0.004 | 66,14 | 3,53 | 0.3058 | 2 5/8 | 3 | 3/16 |

| -334 | 2.725 | 0.020 | 0.21 | 0.004 | 69,32 | 3,53 | 0.3194 | 2 3/4 | 3 1/8 | 3/16 |

| -335 | 2.850 | 0.020 | 0.21 | 0.004 | 72,50 | 3,53 | 0.3330 | 2 7/8 | 3 1/4 | 3/16 |

| -336 | 2.975 | 0.020 | 0.21 | 0.004 | 75,68 | 3,53 | 0.3466 | 3 | 3 3/8 | 3/16 |

| -337 | 3.100 | 0.024 | 0.21 | 0.004 | 78,86 | 3,53 | 0.3602 | 3 1/8 | 3 1/2 | 3/16 |

| -338 | 3.225 | 0.024 | 0.21 | 0.004 | 82,04 | 3,53 | 0.3738 | 3 1/4 | 3 5/8 | 3/16 |

| -339 | 3.350 | 0.024 | 0.21 | 0.004 | 85,22 | 3,53 | 0.3874 | 3 3/8 | 3 3/4 | 3/16 |

| -340 | 3.475 | 0.024 | 0.21 | 0.004 | 88,40 | 3,53 | 0.4010 | 3 1/2 | 4 | 3/16 |

| -341 | 3.600 | 0.024 | 0.21 | 0.004 | 91,58 | 3,53 | 0.4146 | 3 5/8 | 4 1/8 | 3/16 |

| -342 | 3.725 | 0.028 | 0.21 | 0.004 | 94,76 | 3,53 | 0.4282 | 3 3/4 | 4 1/4 | 3/16 |

| -343 | 3.850 | 0.028 | 0.21 | 0.004 | 97,94 | 3,53 | 0.4418 | 3 7/8 | 4 3/8 | 3/16 |

| -344 | 3.975 | 0.028 | 0.21 | 0.004 | 101,12 | 3,53 | 0.4558 | 4 | 4 1/2 | 3/16 |

| -345 | 4.100 | 0.028 | 0.21 | 0.004 | 104,30 | 3,53 | 0.4690 | 4 1/8 | 4 5/8 | 3/16 |

| -346 | 4.225 | 0.030 | 0.21 | 0.004 | 107,48 | 3,53 | 0.4826 | 4 1/4 | 4 3/4 | 3/16 |

| -347 | 4.350 | 0.030 | 0.21 | 0.004 | 110,66 | 3,53 | 0.4962 | 4 3/8 | 4 7/8 | 3/16 |

| -348 | 4.475 | 0.030 | 0.21 | 0.004 | 113,84 | 3,53 | 0.5098 | 4 1/2 | 5 | 3/16 |

| -349 | 4.600 | 0.030 | 0.21 | 0.004 | 117,02 | 3,53 | 0.5243 | 4 5/8 | 5 1/8 | 3/16 |

| -350 | 4.725 | 0.030 | 0.21 | 0.004 | 120,20 | 3,53 | 0.5379 | 4 3/4 | 5 1/4 | 3/16 |

| -351 | 4.850 | 0.030 | 0.21 | 0.004 | 123,38 | 3,53 | 0.5515 | 4 7/8 | 5 3/8 | 3/16 |

| -352 | 4.975 | 0.037 | 0.21 | 0.004 | 126,56 | 3,53 | 0.5652 | 5 | 5 1/2 | 3/16 |

| -353 | 5.100 | 0.037 | 0.21 | 0.004 | 129,74 | 3,53 | 0.5788 | 5 1/8 | 5 5/8 | 3/16 |

| -354 | 5.225 | 0.037 | 0.21 | 0.004 | 132,92 | 3,53 | 0.5924 | 5 1/4 | 5 3/4 | 3/16 |

| -355 | 5.350 | 0.037 | 0.21 | 0.004 | 136,10 | 3,53 | 0.6060 | 5 3/8 | 5 7/8 | 3/16 |

| -356 | 5.475 | 0.037 | 0.21 | 0.004 | 139,28 | 3,53 | 0.6197 | 5 1/2 | 6 | 3/16 |

| -357 | 5.600 | 0.037 | 0.21 | 0.004 | 142,46 | 3,53 | 0.6333 | 5 5/8 | 6 1/8 | 3/16 |

| -358 | 5.725 | 0.037 | 0.21 | 0.004 | 145,64 | 3,53 | 0.6469 | 5 3/4 | 6 1/4 | 3/16 |

| -359 | 5.850 | 0.037 | 0.21 | 0.004 | 148,82 | 3,53 | 0.6605 | 5 7/8 | 6 3/8 | 3/16 |

| -360 | 5.975 | 0.037 | 0.21 | 0.004 | 152,00 | 3,53 | 0.6742 | 6 | 6 1/2 | 3/16 |

| -361 | 6.225 | 0.037 | 0.21 | 0.004 | 158,36 | 3,53 | 0.7014 | 6 1/4 | 6 5/8 | 3/16 |

| -362 | 6.475 | 0.040 | 0.21 | 0.004 | 164,72 | 3,53 | 0.7287 | 6 1/2 | 6 7/8 | 3/16 |

| -363 | 6.725 | 0.040 | 0.21 | 0.004 | 171,08 | 3,53 | 0.7559 | 6 3/4 | 7 1/8 | 3/16 |

| -364 | 6.975 | 0.040 | 0.21 | 0.004 | 177,44 | 3,53 | 0.7832 | 7 | 7 3/8 | 3/16 |

| -365 | 7.225 | 0.045 | 0.21 | 0.004 | 183,80 | 3,53 | 0.8104 | 7 1/4 | 7 5/8 | 3/16 |

| -366 | 7.475 | 0.045 | 0.21 | 0.004 | 190,16 | 3,53 | 0.8379 | 7 1/2 | 7 7/8 | 3/16 |

| -367 | 7.725 | 0.045 | 0.21 | 0.004 | 196,52 | 3,53 | 0.8649 | 7 3/4 | 8 1/8 | 3/16 |

| -368 | 7.975 | 0.045 | 0.21 | 0.004 | 202,88 | 3,53 | 0.8922 | 8 | 8 3/8 | 3/16 |

| -369 | 8.225 | 0.050 | 0.21 | 0.004 | 209,24 | 3,53 | 0.9194 | 8 1/4 | 8 5/8 | 3/16 |

| -370 | 8.475 | 0.050 | 0.21 | 0.004 | 215,60 | 3,53 | 0.9467 | 8 1/2 | 8 7/8 | 3/16 |

| -371 | 8.725 | 0.050 | 0.21 | 0.004 | 221,96 | 3,53 | 0.9739 | 8 3/4 | 9 1/8 | 3/16 |

| -372 | 8.975 | 0.050 | 0.21 | 0.004 | 228,32 | 3,53 | 1.0011 | 9 | 9 3/8 | 3/16 |

| -373 | 9.225 | 0.055 | 0.21 | 0.004 | 234,68 | 3,53 | 1.0284 | 9 1/4 | 9 5/8 | 3/16 |

| -374 | 9.475 | 0.055 | 0.21 | 0.004 | 241,04 | 3,53 | 1.0557 | 9 1/2 | 9 7/8 | 3/16 |

| -425 | 4.475 | 0.033 | 0.275 | 0.006 | 113,84 | 6,99 | 0.8863 | 4 1/2 | 5 | 1/4 |

| -426 | 4.600 | 0.033 | 0.275 | 0.006 | 117,02 | 6,99 | 0.9079 | 4 5/8 | 5 1/8 | 1/4 |

| -427 | 4.725 | 0.033 | 0.275 | 0.006 | 120,20 | 6,99 | 0.9330 | 4 3/4 | 5 1/4 | 1/4 |

| -428 | 4.850 | 0.033 | 0.275 | 0.006 | 123,38 | 6,99 | 0.9563 | 4 7/8 | 5 3/8 | 1/4 |

| -429 | 4.975 | 0.037 | 0.275 | 0.006 | 126,56 | 6,99 | 0.9796 | 5 | 5 1/2 | 1/4 |

| -430 | 5.100 | 0.037 | 0.275 | 0.006 | 129,74 | 6,99 | 1.0030 | 5 1/8 | 5 5/8 | 1/4 |

| -431 | 5.225 | 0.037 | 0.275 | 0.006 | 132,92 | 6,99 | 1.0263 | 5 1/4 | 5 3/4 | 1/4 |

| -432 | 5.350 | 0.037 | 0.275 | 0.006 | 136,10 | 6,99 | 1.0496 | 5 3/8 | 5 7/8 | 1/4 |

| -433 | 5.475 | 0.037 | 0.275 | 0.006 | 139,28 | 6,99 | 1.0729 | 5 1/2 | 6 | 1/4 |

| -434 | 5.600 | 0.037 | 0.275 | 0.006 | 142,46 | 6,99 | 1.0962 | 5 5/8 | 6 1/8 | 1/4 |

| -435 | 5.725 | 0.037 | 0.275 | 0.006 | 145,64 | 6,99 | 1.1196 | 5 3/4 | 6 1/4 | 1/4 |

| -436 | 5.850 | 0.037 | 0.275 | 0.006 | 148,82 | 6,99 | 1.1429 | 5 7/8 | 6 3/8 | 1/4 |

| -437 | 5.975 | 0.037 | 0.275 | 0.006 | 152,00 | 6,99 | 1.1662 | 6 | 6 1/2 | 1/4 |

| -438 | 6.225 | 0.037 | 0.275 | 0.006 | 158,36 | 6,99 | 1.2129 | 6 1/4 | 6 3/4 | 1/4 |

| -439 | 6.475 | 0.040 | 0.275 | 0.006 | 164,72 | 6,99 | 1.2595 | 6 1/2 | 7 | 1/4 |

| -440 | 6.725 | 0.040 | 0.275 | 0.006 | 171,08 | 6,99 | 1.3062 | 6 3/4 | 7 1/4 | 1/4 |

| -441 | 6.975 | 0.040 | 0.275 | 0.006 | 177,44 | 6,99 | 1.3528 | 7 | 7 1/2 | 1/4 |

| -442 | 7.225 | 0.045 | 0.275 | 0.006 | 183,80 | 6,99 | 1.3995 | 7 1/4 | 7 3/4 | 1/4 |

| -443 | 7.475 | 0.045 | 0.275 | 0.006 | 190,16 | 6,99 | 1.4461 | 7 1/2 | 8 | 1/4 |

| -444 | 7.725 | 0.045 | 0.275 | 0.006 | 196,52 | 6,99 | 1.4928 | 7 3/4 | 8 1/4 | 1/4 |

| -445 | 7.975 | 0.045 | 0.275 | 0.006 | 202,88 | 6,99 | 1.5394 | 8 | 8 1/2 | 1/4 |

| -446 | 8.475 | 0.045 | 0.275 | 0.006 | 215,60 | 6,99 | 1.6327 | 8 1/2 | 9 | 1/4 |

| -447 | 8.975 | 0.055 | 0.275 | 0.006 | 228,32 | 6,99 | 1.7260 | 9 | 9 1/2 | 1/4 |

| -448 | 9.475 | 0.055 | 0.275 | 0.006 | 241,04 | 6,99 | 1.8193 | 9 1/2 | 10 | 1/4 |

| -449 | 9.975 | 0.055 | 0.275 | 0.006 | 253,76 | 6,99 | 1.9126 | 10 | 10 1/2 | 1/4 |

| -450 | 10.475 | 0.060 | 0.275 | 0.006 | 266,48 | 6,99 | 2.0059 | 10 1/2 | 11 | 1/4 |

| -451 | 10.975 | 0.060 | 0.275 | 0.006 | 279,20 | 6,99 | 2.0992 | 11 | 11 1/2 | 1/4 |

| -452 | 11.475 | 0.060 | 0.275 | 0.006 | 291,20 | 6,99 | 2.1925 | 11 1/2 | 12 | 1/4 |

| -453 | 11.975 | 0.060 | 0.275 | 0.006 | 304,64 | 6,99 | 2.2858 | 12 | 12 1/2 | 1/4 |

| -454 | 12.475 | 0.060 | 0.275 | 0.006 | 317,36 | 6,99 | 2.3791 | 12 1/2 | 13 | 1/4 |

| -455 | 12.975 | 0.060 | 0.275 | 0.006 | 330,08 | 6,99 | 2.4724 | 13 | 13 1/2 | 1/4 |

| -456 | 13.475 | 0.070 | 0.275 | 0.006 | 342,80 | 6,99 | 2.5657 | 13 1/2 | 14 | 1/4 |

| -457 | 13.975 | 0.070 | 0.275 | 0.006 | 355,52 | 6,99 | 2.6590 | 14 | 14 1/2 | 1/4 |

| -458 | 14.475 | 0.070 | 0.275 | 0.006 | 368,24 | 6,99 | 2.7523 | 14 1/2 | 15 | 1/4 |

| -459 | 14.975 | 0.070 | 0.275 | 0.006 | 380,96 | 6,99 | 2.8456 | 15 | 15 1/2 | 1/4 |

| -460 | 15.475 | 0.070 | 0.275 | 0.006 | 393,68 | 6,99 | 2.9389 | 15 1/2 | 16 | 1/4 |

| -461 | 15.955 | 0.075 | 0.275 | 0.006 | 405,90 | 6,99 | 3.0350 | 16 | 16 1/2 | 1/4 |

| -462 | 16.455 | 0.075 | 0.275 | 0.006 | 418,62 | 6,99 | 3.1285 | 16 1/2 | 17 | 1/4 |

| -463 | 16.955 | 0.080 | 0.275 | 0.006 | 431,34 | 6,99 | 3.2220 | 17 | 17 1/2 | 1/4 |

| -464 | 17.455 | 0.085 | 0.275 | 0.006 | 444,06 | 6,99 | 3.3155 | 17 1/2 | 18 | 1/4 |

| -465 | 17.955 | 0.085 | 0.275 | 0.006 | 456,78 | 6,99 | 3.4090 | 18 | 18 1/2 | 1/4 |

| -466 | 18.455 | 0.085 | 0.275 | 0.006 | 469,50 | 6,99 | 3.5025 | 18 1/2 | 19 1/4 | 1/4 |

| -467 | 18.955 | 0.090 | 0.275 | 0.006 | 482,22 | 6,99 | 3.5960 | 19 | 19 1/2 | 1/4 |

| -468 | 19.455 | 0.090 | 0.275 | 0.006 | 494,94 | 6,99 | 3.6895 | 19 1/2 | 20 | 1/4 |

| -469 | 19.955 | 0.095 | 0.275 | 0.006 | 507,66 | 6,99 | 3.7830 | 20 | 20 1/2 | 1/4 |

| -470 | 20.955 | 0.095 | 0.275 | 0.006 | 533,10 | 6,99 | 3.9700 | 21 | 21 1/2 | 1/4 |