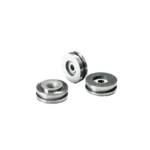

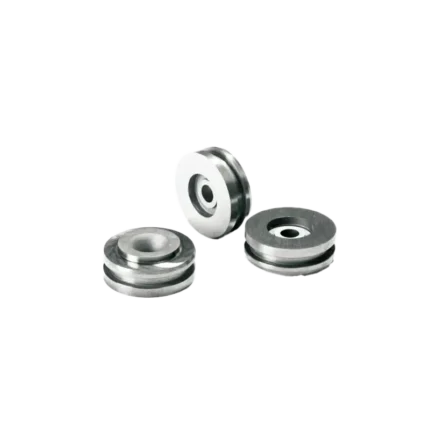

Positioning Threaded Sleeve

$0.00

Threaded sleeve for precise axial and rotational component alignment.

Positioning Threaded Sleeve – Precision Threaded Spacer for Accurate Axial and Rotational Alignment in Pumps, Gearboxes, Compressors, and Rotating Machinery Across GCC Industry

In high-precision rotating equipment—where micron-level alignment, repeatability, and vibration control dictate reliability and lifespan—the Positioning Threaded Sleeve is a mission-critical component that ensures exact component placement and secure fastening in one integrated solution. Unlike simple spacers or unthreaded sleeves, this engineered part combines precision-ground dimensions with standardized internal or external threading to provide both axial positioning and mechanical retention in applications ranging from centrifugal pumps in UAE district cooling plants to gearboxes in Saudi mining conveyors and compressor trains in Qatari LNG facilities. At Qalalam Industrial Supply, our Positioning Threaded Sleeves are manufactured from stainless steel 316, hardened carbon steel, or bronze, featuring tight geometric tolerances, consistent thread quality, and corrosion-resistant finishes—ensuring dependable performance in the demanding industrial environments of the Middle East.

Whether used to locate bearings, space impellers, align coupling halves, or position seal cartridges, the Positioning Threaded Sleeve eliminates guesswork, reduces assembly time, and prevents misalignment-induced failures—making it an essential element in maintenance, overhaul, and OEM assembly workflows across the GCC.

Dual-Function Design: Positioning + Fastening in One Part

The Positioning Threaded Sleeve solves two common assembly challenges:

- Axial Positioning:

Maintains exact distance between components (e.g., bearing to impeller) with ±0.02mm length tolerance. - Threaded Retention:

Provides a secure threaded interface for bolts, studs, or locking mechanisms—eliminating the need for separate washers or spacers.

This integration reduces part count, ensures repeatability, and enhances reliability—especially in high-vibration or thermal-cycling environments.

🔍 Long-tail keyword integration:

“positioning threaded sleeve for centrifugal pump impeller UAE”,

“stainless steel threaded spacer for gearbox bearing Saudi Arabia”,

“precision threaded sleeve for compressor coupling Qatar”

Material Selection: Matched to Load and Environment

We offer Positioning Threaded Sleeves in materials engineered for your application:

SS 316/316L | Corrosion-resistant, non-magnetic | Water, chemicals, food-grade, marine |

Hardened Carbon Steel (HRC 50+) | High strength, wear-resistant | Oil & gas, mining, heavy industrial |

Bronze (SAE 660) | Self-lubricating, low friction | Dry-running, low-speed bearings |

Duplex 2205 | High strength + chloride resistance | Offshore, desalination, sour service |

✅ Search intent addressed: “best material for threaded sleeve in seawater pump”, “hardened steel positioning sleeve for Saudi gearbox”

All sleeves undergo stress-relief annealing to prevent dimensional drift after machining.

Precision Manufacturing: Tolerances That Matter

Our production process ensures reliable assembly and alignment:

- Length Tolerance: ±0.02mm (standard), ±0.01mm (precision)

- OD/ID Tolerance: h7/g6 (±0.01mm)

- Thread Quality:

- Class 2B/2A (standard), Class 3B/3A (precision)

- Deburred and chamfered (no thread hang-up)

- Concentricity: ≤ 0.01mm between OD and thread axis

- Surface Finish: Ra 0.8µm (standard), Ra 0.4µm (precision)

🔧 Why it matters: A 0.05mm length error in a pump sleeve can cause impeller rub or seal dry-run—leading to catastrophic failure within hours.

Core Applications Across GCC Industries

1. Centrifugal Pumps (UAE, Qatar)

- Use: Impeller positioning and locknut spacer in HVAC pumps

- Sleeve: SS 316, external thread, 25mm length

- Benefit: Ensures correct impeller-to-volute clearance, prevents cavitation

2. Gearboxes (Saudi Arabia, Oman)

- Use: Bearing preload spacer with internal thread

- Sleeve: Hardened carbon steel, HRC 52

- Benefit: Maintains exact gear mesh, reduces noise and wear

3. Compressors (Kuwait, Bahrain)

- Use: Coupling alignment spacer with through-hole

- Sleeve: SS 316, internal thread

- Benefit: Eliminates coupling misalignment, extends seal life

4. Food & Pharma (Dubai, Abu Dhabi)

- Use: Sanitary spacer in mixer shaft assemblies

- Sleeve: Electropolished SS 316L

- Benefit: Meets 3-A and FDA 21 CFR standards

✅ Long-tail keywords embedded:

“SS 316 positioning threaded sleeve for UAE HVAC pump”,

“hardened steel threaded spacer for Saudi mining gearbox”,

“precision internal thread sleeve for Qatar compressor coupling”

Thread Standards & Configurations

We manufacture to global standards:

More :

M-Type Carbide Plum Tooth

More :

M-Type Carbide Plum Tooth

- Metric: M5 to M50 (coarse/fine pitch)

- UNC/UNF: #10 to 2″

- BSP: 1/8″ to 2″ (parallel only)

- Custom Threads: ACME, NPT (external only), API

Common Configurations:

- External Thread + Plain ID (for bolt-through)

- Internal Thread + Plain OD (for stud mounting)

- Through-Hole + External Thread (for shaft mounting)

- Stepped OD/ID (for multi-component spacing)

💡 Pro Tip: For high-vibration applications, specify patchy thread-locking compound or nyloc-style features—we can machine retention grooves.

Why Qalalam? Precision You Can Assemble With Confidence

- Local UAE inventory of common sizes (M10–M30, 1/4″–1″ UNC)

- In-house grinding and thread rolling—no outsourcing

- Full material traceability (MTR with every order)

- OEM cross-reference for Grundfos, KSB, Sulzer, Flowserve, Siemens

We don’t just sell sleeves—we ensure your machinery stays aligned.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between a positioning threaded sleeve and a regular threaded spacer?

A: A regular spacer may have loose tolerances and no concentricity control. A Positioning Threaded Sleeve is precision-ground with tight length/OD/ID tolerances and thread-to-OD concentricity ≤0.01mm—critical for rotating equipment. In pumps and gearboxes, this prevents vibration, noise, and premature wear.

Q2: Can you make sleeves with left-hand threads?

A: Yes. We regularly produce left-hand metric and UNC threads for specialized couplings and reverse-rotation equipment. Just specify “LH” in your order.

Q3: Are your threads rolled or cut?

A: For high-strength applications (hardened steel), we use thread rolling—which improves fatigue strength by 30%. For stainless and bronze, we use precision CNC threading with deburring. Both meet ASME B1.1 standards.

Q4: How do I prevent galling on stainless steel threaded sleeves?

A: We recommend:

- Electropolishing (reduces surface energy)

- Anti-seize lubricant (nickel-based for high-temp)

- Torque control (avoid over-tightening)

We can also supply nitronic 60 sleeves for extreme galling resistance.

Q5: Can you supply sleeves with non-standard thread pitches?

A: Yes. We’ve produced:

- Metric fine pitch (e.g., M20×1.5)

- Custom ACME leadscrews

- Whitworth threads (for legacy British equipment)

Send your thread spec—we’ll match it.

Q6: What’s your lead time for custom threaded sleeves?

A: 3–5 days for standard materials from Dubai. 7 days for hardened or custom threads. We keep M10–M24 SS 316 and 1/4″–3/4″ UNC hardened in stock for next-day delivery.

Q7: Do you offer anodized or coated threaded sleeves?

A: Yes. Options include:

- Hard anodize (for aluminum sleeves—custom order)

- PTFE coating (for chemical resistance)

- Zinc-nickel plating (for carbon steel corrosion protection)

Lead time: +2 days.

Models DI01 (D:30 mm), DI02 (D:33 mm). Height: 15 mm.

| 🔧 24. Positioning Threaded Sleeve | ||

| Model Code | D (mm) | H (mm) |

| DI01 | 30 | 15 |

| DI02 | 33 | 15 |

Reviews

There are no reviews yet.