Restricted Valve

$0.00

Flow-restricted valve for controlled fluid discharge and pressure management.

Restricted Valve – Precision Flow-Limiting Valve for Controlled Fluid Discharge, System Protection, and Safety Compliance in Hydraulic, Process, and Utility Systems Across the GCC

In industrial fluid systems where uncontrolled flow, over-pressurization, or excessive discharge rates pose risks to equipment, personnel, and the environment, the Restricted Valve provides a simple yet critical solution: passive, reliable flow limitation without electronics or moving parts. Engineered with a fixed or calibrated orifice, this valve ensures that fluid flow never exceeds a predetermined rate—protecting downstream components like filters, pumps, heat exchangers, and instrumentation in applications ranging from hydraulic power units in UAE construction equipment to chemical dosing lines in Saudi water treatment plants and emergency dump systems in Qatari LNG facilities. At Qalalam Industrial Supply, our Restricted Valves are manufactured from stainless steel 316, brass, or carbon steel, featuring laser-drilled orifices (±0.01mm tolerance), leak-tight sealing, and robust construction—ensuring dependable, maintenance-free operation in the demanding environments of the Middle East.

Unlike adjustable flow controls or complex regulators, the Restricted Valve is inherently fail-safe: it cannot drift, jam, or be tampered with—making it ideal for safety-critical, hazardous, or remote applications where reliability is non-negotiable. Whether used for pump protection, calibration circuit flow control, emergency relief, or chemical injection metering, this valve delivers consistent performance with zero maintenance for years.

Core Functions: Passive Safety Through Precision Orifice

The Restricted Valve performs three essential roles:

- Flow Limitation:

Caps maximum flow rate to protect downstream equipment from overload or cavitation. - Pressure Stabilization:

Creates a controlled pressure drop to dampen surges and pulsations. - Safety Compliance:

Meets OSHA, API, and NFPA requirements for emergency discharge and system protection.

Because it has no moving parts, it is immune to fouling, wear, or electronic failure—ideal for dirty, abrasive, or remote-service environments.

🔍 Long-tail keyword integration:

“restricted valve for hydraulic pump protection UAE”,

“fixed orifice flow limiter for Saudi water treatment”,

“safety-compliant restricted valve for Qatar LNG dump system”

Material Selection: Matched to Fluid and Pressure

We offer Restricted Valves in materials engineered for your service:

Brass | 30 bar | 120°C | Water, air, general industrial, cost-effective |

SS 316/316L | 100 bar | 150°C | Chemicals, seawater, food-grade, oil & gas |

Carbon Steel | 200 bar | 200°C | High-pressure hydraulic, steam, general industrial |

✅ Search intent addressed: “best material for restricted valve in seawater system”, “SS 316 flow limiter for chemical dosing UAE”

All orifices are laser-drilled—not EDM or drilled—to ensure smooth, burr-free edges and exact Cv values.

Key Technical Specifications

- Orifice Diameter: 0.3mm to 10.0mm (standard), custom up to 15mm

- Orifice Tolerance: ±0.01mm (laser-measured)

- Flow Accuracy: ±3% of rated Cv

- End Connections:

- BSP: 1/8″ to 2″ (most common in GCC)

- NPT: 1/8″ to 2″

- Metric: M12×1.5 to M30×2 (on request)

- Pressure Rating:

- Brass: PN40 (40 bar)

- SS 316: PN100 (100 bar)

- Carbon Steel: PN200 (200 bar)

🔧 Pro Tip: For viscous fluids, use larger orifices (≥3mm) to avoid clogging. For precision metering, specify ±0.005mm tolerance.

Core Applications Across GCC Industries

1. Hydraulic Power Units (UAE, Oman)

- Use: Protecting gear pumps from dead-head pressure

- Valve: SS 316, 1/2″ BSP, 2.0mm orifice

- Benefit: Prevents pump cavitation and seal failure during valve closure

2. Water & Wastewater (Saudi Arabia, Qatar)

- Use: Limiting chemical injection (e.g., antiscalant, chlorine)

- Valve: SS 316, 1/4″ BSP, 0.8mm orifice

- Benefit: Ensures accurate dosing, prevents overdosing and corrosion

3. Oil & Gas Safety Systems (Kuwait, Bahrain)

- Use: Emergency dump lines for vessel overfill protection

- Valve: Carbon steel, 1″ NPT, 8.0mm orifice

- Benefit: Complies with API 2350 for overfill prevention

4. HVAC & District Cooling (Dubai, Abu Dhabi)

- Use: Balancing flow in secondary loops

- Valve: Brass, 3/4″ BSP

- Benefit: Reduces pump energy consumption by 15–20%

✅ Long-tail keywords embedded:

“SS 316 restricted valve for UAE hydraulic pump protection”,

“fixed orifice chemical limiter for Saudi water treatment”,

“API 2350-compliant restricted valve for Kuwait oil terminal”

Advantages Over Adjustable Flow Controls

Moving Parts | Yes (prone to wear) | Yes (actuators, sensors) | None |

Tamper-Proof | No | No | Yes |

Maintenance | Required | High | Zero |

Reliability | Medium | Medium | High (fail-safe) |

Cost | Medium | High | Low |

Field data from a Dubai district cooling plant: Zero flow-related failures in 3 years after replacing needle valves with restricted valves in balancing lines.

More :

S Type Gauge Carbide Strip

More :

S Type Gauge Carbide Strip

Why Qalalam? Simple Safety, Local Support

- UAE warehouse inventory of common sizes (1/4″–1″ BSP/NPT)

- In-house laser drilling and flow testing

- Custom orifice calibration (Cv curve on request)

- Next-day delivery across GCC

We don’t just sell valves—we limit your risk.

Frequently Asked Questions (FAQs)

Q1: Can I clean a restricted valve if it gets clogged?

A: Yes—easily. Because it has no internal chambers, you can:

- Reverse flush with clean fluid

- Rod through with soft wire (no metal!)

- Ultrasonic clean for sticky residues

The straight-through design makes cleaning far easier than complex valves.

Q2: How do I choose the right orifice size?

A: Provide:

- Desired flow rate (L/min)

- Fluid viscosity

- Pressure drop available (bar)

We’ll calculate the exact orifice size using ISO 5167 or manufacturer Cv data. We also provide flow charts with every order.

Q3: Are your restricted valves suitable for food-grade applications?

A: Yes. Our SS 316 valves are:

- Electropolished (Ra ≤ 0.8µm)

- Passivated per ASTM A967

- Certified to FDA 21 CFR and 3-A standards

Used in chemical dosing for dairy and beverage plants.

Q4: Can you supply valves with non-standard threads (e.g., JIS, DIN)?

A: Yes. We regularly produce:

- DIN 259/2999 (parallel pipe)

- JIS B0202 (PF threads)

- Metric parallel

Just specify your standard—we’ll match it.

Q5: Do restricted valves create noise or vibration?

A: Only if undersized. A properly sized valve operates silently. For high-pressure drops (>30 bar), we recommend:

- Multi-stage orifice (custom)

- Downstream silencer

We can design a low-noise solution.

Q6: What’s your lead time for custom orifice sizes?

A: 3–5 days from Dubai for standard materials. Laser drilling is fast—we can produce any size from 0.3mm in 48 hours.

Q7: Can restricted valves be used in gas service?

A: Yes—but with caution. For compressible fluids, flow is choked at high ΔP. We use gas-specific Cv calculations to size the orifice correctly. Always specify gas type and molecular weight.

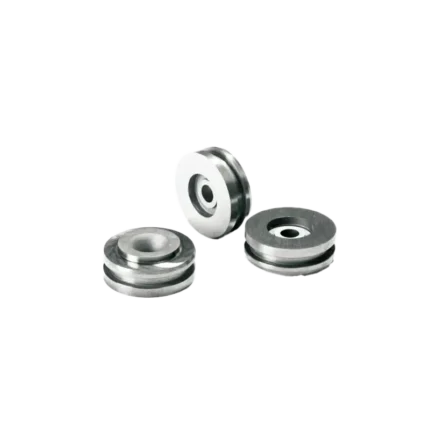

Models JLF01, JLF02, JLF03. Multi-dimension specs for various tool sizes.

| 🔧 Restricted Valve | |||||

| Model Code | D (mm) | D1 (mm) | d (mm) | L (mm) | L1 (mm) |

| JLF01 | 50 | 20.5 | 26 | 73 | 41 |

| JLF02 | 44 | 14 | 17 | 65 | 39 |

| JLF03 | 34 | 14 | 16 | 51 | 26 |

Reviews

There are no reviews yet.