Bore-hole Sealing Sleeve

$0.00

Specialized sleeve for sealing and protecting borehole casings.

Bore-hole Sealing Sleeve – High-Integrity, Corrosion-Resistant Sleeve for Zonal Isolation, Casing Protection, and Fluid Migration Control in Water Wells, Geothermal, and Oil & Gas Boreholes Across the GCC

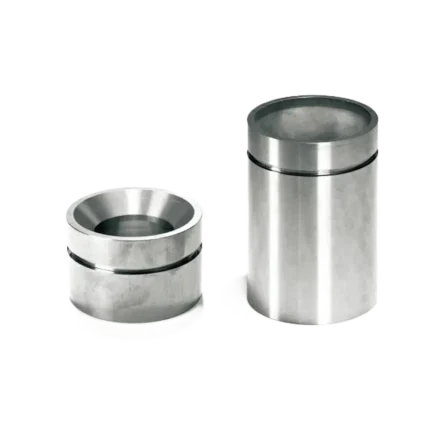

In subsurface operations where fluid migration, casing corrosion, and formation cross-flow threaten well integrity and environmental safety, the Bore-hole Sealing Sleeve serves as a critical engineered barrier. Designed to be installed inside well casings or open boreholes, this robust sleeve isolates zones, protects base pipe from abrasive or corrosive fluids, and provides a reliable sealing surface for packers, inflatable plugs, or cement bonding in water supply wells, geothermal loops, monitoring boreholes, and oil & gas injection/abandonment operations across the UAE, Saudi Arabia, Oman, and beyond. At Qalalam Industrial Supply, our Bore-hole Sealing Sleeves are manufactured from high-grade stainless steel (316L, Duplex 2205), carbon steel with epoxy lining, or specialty alloys, engineered to withstand saline groundwater, high temperatures, abrasive sand, and chemical exposure in the harsh subsurface environments of the Middle East.

Unlike temporary plugs or standard casing patches, the Bore-hole Sealing Sleeve is a permanent or semi-permanent engineered solution that ensures long-term zonal isolation—critical for groundwater protection, reservoir management, and regulatory compliance in GCC regions where water scarcity and environmental regulations are stringent.

Core Functions: Sealing, Protection, and Isolation

The Bore-hole Sealing Sleeve performs three essential roles:

- Zonal Isolation:

Prevents vertical fluid movement between aquifers or formations—critical for drinking water safety and geothermal efficiency. - Casing Protection:

Shields the original well casing from abrasion (sand), corrosion (chlorides, H₂S), and erosion (high-velocity flow). - Sealing Interface:

Provides a smooth, compatible surface for packers, bridge plugs, or cement to achieve leak-tight isolation.

This makes it indispensable for well rehabilitation, abandonment, monitoring well construction, and geothermal loop integrity.

🔍 Long-tail keyword integration:

“bore-hole sealing sleeve for water well UAE”,

“Duplex 2205 sealing sleeve for geothermal borehole Saudi Arabia”,

“corrosion-resistant casing sleeve for monitoring well Oman”

Material Selection: Matched to Subsurface Conditions

We offer sleeves in materials engineered for your well environment:

SS 316L | Excellent corrosion resistance | 150°C | Freshwater, mild brine, general water wells |

Duplex 2205 | High strength + chloride resistance | 200°C | Seawater intrusion, desalination recharge, offshore |

Carbon Steel + FBE Coating | Cost-effective, abrasion-resistant | 120°C | Non-corrosive zones, temporary isolation |

Hastelloy C276 | Resists H₂S, acids, chlorides | 400°C | Sour oil/gas, acid injection, harsh geothermal |

✅ Search intent addressed: “best material for borehole sleeve in saline aquifer UAE”, “Duplex 2205 sealing sleeve for Saudi geothermal well”

All sleeves include full material traceability (MTR) and hydrostatic pressure testing.

Design & Installation Features

- Diameter Range: 50mm to 300mm (2″ to 12″)

- Length: 1m to 6m standard (custom up to 12m)

- Wall Thickness: 3mm to 10mm (based on collapse pressure)

- End Connections:

- Plain end (for welding or cementing)

- Threaded (API LCSG) for mechanical joining

- Flanged for surface installations

- Surface Finish:

- Internal: Ra ≤ 1.6µm (for packer compatibility)

- External: Coated or bare (per spec)

🔧 Pro Tip: For packer installations, specify internal diameter tolerance h9 and no weld seams in the sealing zone.

Core Applications Across GCC Industries

1. Municipal Water Wells (UAE, Qatar)

- Use: Rehabilitating old wells with corroded casings

- Sleeve: SS 316L, 150mm OD, 5m length

- Benefit: Restores well integrity, prevents seawater intrusion in coastal aquifers

2. Geothermal Energy (Saudi Arabia, Oman)

- Use: Isolating zones in deep geothermal loops

- Sleeve: Duplex 2205, 200mm OD

- Benefit: Withstands 200°C brine + 45,000 ppm chlorides for 25+ years

3. Environmental Monitoring (Kuwait, Bahrain)

- Use: Sealing monitoring boreholes near industrial sites

- Sleeve: SS 316L with plain ends

- Benefit: Prevents cross-contamination between aquifers

4. Oil & Gas Abandonment (UAE, Saudi)

- Use: Permanent plugging of decommissioned wells

- Sleeve: Carbon steel + FBE, cemented in place

- Benefit: Meets ADNOC, Aramco, and EPA abandonment standards

✅ Long-tail keywords embedded:

“SS 316L borehole sealing sleeve for UAE water well rehab”,

“Duplex 2205 geothermal casing sleeve Saudi”,

“monitoring well sealing sleeve for Kuwait environmental compliance”

Performance Advantages Over Alternatives

Gravel Pack Only | 5–10 years | None | Limited |

Cement Squeeze | 10–15 years | Moderate | Good |

Bore-hole Sealing Sleeve | 25–50+ years | Excellent (with proper material) | Full (API, ISO, GCC standards) |

Field data from an Abu Dhabi water authority: Zero well failures in 8 years after sleeve-based rehabilitation.

Why Qalalam? Built for GCC Subsurface Challenges

- Local UAE inventory of common sizes (4″, 6″, 8″ OD)

- In-house hydrotesting and coating inspection

- Compliance with ADNOC, Aramco, and GSO standards

- Engineering support for well design and installation

We don’t just sell sleeves—we protect your groundwater and well integrity.

Frequently Asked Questions (FAQs)

Q1: Can I install a bore-hole sealing sleeve in an existing well?

A: Yes—via wireline, coiled tubing, or drilling rig. Sleeves can be:

- Cemented in place (most common)

- Mechanically expanded (for open hole)

- Packer-anchored (for temporary isolation)

We provide installation engineering support for your method.

Q2: What’s the difference between a sealing sleeve and a casing liner?

A: A casing liner is structural—it carries load and replaces damaged casing. A sealing sleeve is non-structural—its primary role is isolation and protection. Liners are thicker (8–12mm); sleeves are thinner (3–8mm) and optimized for sealing.

Q3: Do your sleeves comply with UAE groundwater regulations?

A: Yes. Our SS 316L and Duplex 2205 sleeves meet:

- UAE MOCCAE environmental standards

- GCC Standardization Organization (GSO) requirements

- ISO 11960 for well tubulars

We provide compliance documentation with every order.

Q4: Can you supply sleeves with pre-installed packer bores?

A: Yes. We machine precise internal diameters at specific depths for:

- Inflatable packers

- Mechanical bridge plugs

- Cement retainers

Just provide your packer model and setting depth.

Q5: How do you prevent galvanic corrosion between sleeve and original casing?

A: We recommend:

- Insulating centralizers (non-metallic)

- Matching materials (e.g., SS sleeve in SS casing)

- Dielectric coatings on carbon steel casings

Our engineers can model galvanic risk for your well.

Q6: What’s your lead time for custom-length sleeves?

A: 7–10 days from Dubai for standard materials. 12–15 days for Hastelloy or custom coatings. We keep 4″–8″ SS 316L in stock for emergency rehab.

Q7: Can sleeves be used in horizontal or deviated wells?

A: Yes—with centralizers to ensure even cement distribution. For high-angle wells (>60°), we recommend shorter sections (1–2m) for easier installation.

Reviews

There are no reviews yet.