Carbide Rods (Punching & Mandrel)

$0.00

Solid tungsten carbide rods for punching tools, mandrels, and precision shafts.

Carbide Rods (Punching & Mandrel) – Ultra-Hard, High-Precision Tungsten Carbide Rods for Metal Forming, Tube Drawing, and Precision Shaft Applications

In the high-stress world of metal forming, tube production, and precision engineering, the performance of every punch, mandrel, and guide shaft hinges on one critical attribute: material integrity under extreme load. Carbide Rods (Punching & Mandrel) are not interchangeable with steel or even hardened tool steel—they are engineered solutions designed to withstand compressive forces exceeding 5,000 MPa, abrasive particle flow, and cyclic thermal loading without deformation, wear, or fatigue failure. From aluminum extrusion lines in Dubai to copper tube drawing mills in Saudi Arabia and precision bearing mandrels in aerospace assembly plants across the GCC, our Carbide Rods deliver micron-level dimensional stability, exceptional surface finish, and service life measured in millions of cycles—not hours.

At Qalalam Industrial Supply, we specialize in solid, monolithic tungsten carbide rods manufactured using advanced powder metallurgy, hot isostatic pressing (HIP), and precision centerless grinding. Unlike segmented or coated alternatives, our rods are fully dense, pore-free, and stress-relieved—ensuring they maintain straightness, roundness, and surface quality even after prolonged exposure to high-pressure forming, abrasive slurries, or elevated temperatures. Whether you’re punching holes in stainless steel strips, drawing seamless copper tubing, or guiding fragile optical fibers, our Carbide Rods provide the rigidity, wear resistance, and reliability your high-value processes demand.

Two Critical Roles: Punching vs. Mandrel – Same Material, Different Demands

While both use solid carbide rods, their operational requirements differ significantly:

1. Punching Rods – For High-Speed, High-Force Perforation

Used in progressive dies, stamping presses, and powder compacting, punching rods must resist:

- Compressive buckling under 100+ ton forces

- Edge chipping from shearing hard materials (e.g., spring steel, Inconel)

- Galling from repeated contact with workpiece material

→ Our solution: Medium-grain carbide (0.8–1.2µm) with 8–10% cobalt for optimal toughness. Tip geometry is precision-ground with micro-chamfers to prevent fracture initiation.

2. Mandrel Rods – For Seamless Tube & Wire Drawing

Used as internal forming cores in tube drawing benches and wire sizing lines, mandrels must:

- Maintain perfect cylindrical geometry under radial pressure

- Provide mirror-smooth surface to prevent marking on drawn material

- Resist erosion from lubricant abrasives and thermal cycling

→ Our solution: Fine-grain carbide (0.5–0.8µm) with 6–7% cobalt, centerless-ground to Ra ≤ 0.2µm, and polished to eliminate micro-scratches.

🔍 Long-tail keyword integration:

“carbide punching rods for stainless steel stamping UAE”,

“high-precision carbide mandrel rods for copper tube drawing Saudi Arabia”,

“wear-resistant carbide rods for powder compacting Kuwait”

Material Science: Beyond Hardness – The Role of Microstructure

Hardness alone doesn’t guarantee performance. Our rods are engineered for balanced properties:

Compressive Strength | Prevents buckling in punching | > 5,200 MPa via HIP densification |

Transverse Rupture Strength (TRS) | Resists fracture under bending | > 2,800 MPa via controlled cobalt distribution |

Grain Uniformity | Ensures even wear | Laser-diffraction controlled WC powder |

Residual Stress | Prevents warping during use | Post-sintering annealing at 800°C |

Standard Grades:

- PR-10: Coarse grain, 10% Co – Heavy-duty punching

- MR-7: Fine grain, 7% Co – Precision mandrels

- MR-AM: Non-magnetic, Ni-binder – Electronics & medical

✅ Search intent addressed: “best carbide grade for tube drawing mandrel”, “high TRS carbide rods for metal stamping”

Precision Manufacturing: From Sintered Billet to Micron Accuracy

Our production process ensures zero compromise on geometry:

- Isostatic Pressing: 200 MPa for uniform green density

- Vacuum Sintering: 1,420°C for full densification

- HIP Treatment: 150 MPa Argon pressure to eliminate porosity

- Stress Relief: 800°C anneal to prevent post-machining drift

- Centerless Grinding:

- Diameter tolerance: ±0.005mm

- Roundness: ≤ 0.003mm

- Straightness: ≤ 0.01mm per 100mm length

- Surface finish: Ra 0.2–0.8µm (standard), Ra 0.05µm (polished)

🔧 Why it matters: In tube drawing, a 0.01mm diameter variation causes wall thickness inconsistency—rejecting entire coils in aerospace or medical tubing.

Core Applications Across GCC Industries

1. Metal Stamping & Punching (UAE, Qatar)

- Use: Perforating stainless steel exhaust components

- Rod: PR-10, Ø6mm × 100mm

- Benefit: 500,000+ strokes vs. 80,000 for H13 steel

2. Copper & Aluminum Tube Drawing (Saudi Arabia, Oman)

- Use: Mandrels for 6–20mm OD seamless tubes

- Rod: MR-7, polished finish

- Benefit: Zero surface marks, 3x longer life vs. tool steel

3. Powder Metallurgy (Kuwait, Bahrain)

- Use: Punch rods for automotive sprockets

- Rod: PR-10 with radiused tip

- Benefit: No galling, consistent green density

4. Aerospace & Medical Tubing (Dubai)

- Use: Mandrels for Inconel and titanium tubes

- Rod: MR-AM (non-magnetic), Ra 0.05µm

- Benefit: Meets ASTM F899 and AMS 4928 standards

✅ Long-tail keywords embedded:

“carbide mandrel rods for seamless copper tube UAE”,

“non-magnetic carbide punching rods for medical devices”,

“high-TRS carbide rods for stainless steel stamping Saudi”

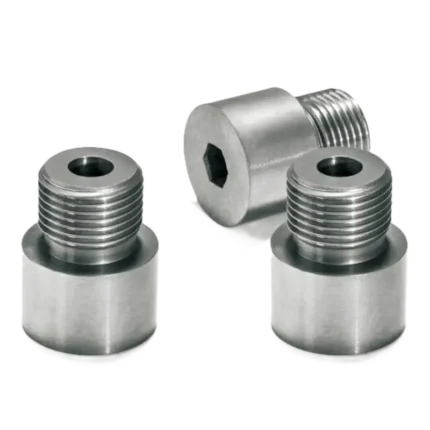

Customization: Beyond Standard Catalog

We offer full customization:

- Diameter: 0.5mm to 50mm

- Length: Up to 1,000mm (straightness guaranteed)

- Tolerances: Down to ±0.002mm (for aerospace)

- End Features:

- Threaded ends (metric, UNF)

- Flatted sections for wrench grip

- Tapered tips for pilot alignment

- Marking: Laser-etched part number or logo

💡 Pro Tip: For long mandrels (>500mm), we use double-supported grinding to maintain straightness—critical for consistent tube ID.

Why Qalalam? Precision You Can Measure

- In-house metrology lab: CMM, roundness tester, profilometer

- Full material traceability: MTR with TRS, hardness, density

- UAE inventory: 50+ standard sizes in stock for next-day delivery

- Technical support: Help selecting grade, geometry, and finish

We don’t just sell rods—we enable your high-precision forming.

Frequently Asked Questions (FAQs)

Q1: What’s the maximum length you can produce while maintaining straightness?

A: 1,000mm with straightness ≤ 0.03mm—achieved through multi-pass centerless grinding with real-time laser monitoring. For lengths beyond that, we offer segmented rods with precision joints, but monolithic is always preferred for critical applications.

Q2: Can your carbide rods be used in high-temperature drawing (e.g., titanium at 600°C)?

A: Yes. Our MR-7 grade retains strength up to 800°C. For extreme temps, we offer chromium-doped carbide (MR-7Cr) that resists oxidation and thermal softening. Common in aerospace tube mills processing Inconel 718.

Q3: How do I prevent carbide rods from cracking during installation in a punch holder?

A: Never press-fit dry. Always:

- Use thermal expansion: Heat holder to 150°C, cool rod to -20°C (dry ice)

- Apply anti-seize lubricant (e.g., Molykote)

- Avoid eccentric loading—use alignment sleeves

We provide a free installation guide with torque and temperature specs.

Q4: Are your rods suitable for EDM machining if I need custom end features?

A: Absolutely. Our rods are HIP-treated and stress-relieved, making them ideal for sink or wire EDM. Just specify “EDM-ready” when ordering—we’ll ensure ultra-low porosity.

Q5: What’s the difference between a mandrel rod and a guide rod?

A: A mandrel defines the internal diameter of a drawn tube (in direct contact with material). A guide rod only aligns the workpiece without forming it. Mandrels require higher surface finish and tighter tolerances—we polish them to Ra ≤ 0.2µm; guides can be Ra ≤ 0.8µm.

Q6: Do you offer rods with internal cooling channels?

A: Not in solid carbide—drilling micro-channels compromises structural integrity. However, we offer carbide-tipped steel mandrels with internal coolant passages for high-heat applications. The carbide tip provides wear resistance; the steel body handles cooling.

Q7: Can you recoat or regrind worn carbide rods?

A: Regrinding: yes—we can restore diameter and surface finish if enough material remains (min. 0.2mm stock). Recoating: no—carbide is monolithic; coatings peel under load. We recommend predictive replacement based on your cycle count.

Reviews

There are no reviews yet.