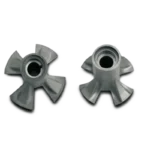

Carbide Stator

$0.00

Solid carbide stator for high-abrasion mud motor applications.

Carbide Stator – Solid Tungsten Carbide Power Section for High-Performance, Abrasion-Resistant Mud Motors in Extreme GCC Drilling Environments

In directional and horizontal drilling operations where elastomer stators fail within hours due to sand abrasion, high temperatures, or chemical degradation, the Carbide Stator represents the ultimate evolution in mud motor technology. Engineered as a monolithic, helically-lobed stator from solid tungsten carbide, this component eliminates the limitations of rubber entirely—delivering unmatched wear resistance, thermal stability up to 500°C, and consistent torque output in the most aggressive formations across Saudi Arabia, the UAE, Oman, and Qatar. At Qalalam Industrial Supply, our Carbide Stators are precision-machined from ultra-fine-grain tungsten carbide (0.4–0.8µm) using advanced CNC grinding and laser metrology, featuring API-compatible geometries, thermal shock resistance, and direct fitment with standard rotors—enabling 3–5x longer runs, higher ROP in abrasive zones, and zero downtime from stator washout in Middle Eastern wells.

Whether drilling through quartz-rich Khuff gas reservoirs, abrasive Unayzah sandstone, or high-temperature carbonate sections, our Carbide Stator ensures your mud motor delivers reliable power, precise toolface control, and maximum footage per trip—transforming challenging wells into economic successes.

Why Solid Carbide? Solving the Elastomer Failure Crisis

Traditional nitrile or HSN elastomer stators degrade rapidly in harsh downhole conditions due to:

- Abrasion: Sand and formation grit cut through rubber in <30 hours

- Swelling: Oil-based mud (OBM) causes volumetric expansion and loss of sealing

- Thermal Degradation: Temperatures >150°C harden and crack elastomers

- Chemical Attack: H₂S, acids, or solvents break polymer chains

Our Carbide Stator solves all four:

- Extreme hardness (90–92 HRA) resists even 100-mesh sand

- Zero swelling in any fluid—OBM, WBM, foam, or acid

- Stable up to 500°C—no thermal degradation

- Chemically inert—immune to H₂S, acids, and solvents

🔍 Long-tail keyword integration:

“solid carbide stator for Khuff formation drilling UAE”,

“abrasion-resistant mud motor stator for Saudi Unayzah”,

“high-torque carbide stator for Omani HPHT well”

Material & Geometry: Engineered for Power and Longevity

We offer Carbide Stators in advanced microstructures:

CS-8U | 0.4–0.6µm | 8% | 92 HRA | High-abrasion, standard torque |

CS-10U | 0.6–0.8µm | 10% | 90 HRA | High-impact, high-torque, thermal cycling |

Key Features:

- Precision Helix Profile: Matched to 1:2, 2:3, 3:4, 4:5 rotor ratios

- Laser-Scanned Surface: Ensures perfect rotor-stator mesh (clearance: 0.1–0.3mm)

- Stress-Relieved: Prevents micro-cracking during thermal shock

- HIP-Treated: Full density, zero internal porosity

✅ Search intent addressed: “best carbide stator for high-sand drilling UAE”, “solid stator for 200°C well in Saudi Arabia”

Core Applications in GCC Drilling

1. Khuff Gas Reservoirs (UAE, Qatar)

- Challenge: High-abrasion sand in carbonate matrix

- Solution: CS-8U carbide stator

- Benefit: 5+ runs per stator vs. 1–2 for elastomer—reduces NPT by 60%

2. Unayzah Formation (Saudi Arabia)

- Challenge: Quartz-rich sandstone, high ROP required

- Solution: CS-10U with reinforced lobes

- Benefit: Maintains stable torque at 300+ RPM, no stator washout

3. Offshore & HPHT Wells (Oman, Kuwait)

- Challenge: Temperatures >180°C, sour gas

- Solution: CS-8U (chemically inert)

- Benefit: No elastomer swelling or H₂S degradation

4. Horizontal & Extended Reach (All GCC)

- Challenge: Long motor runs, high side loads

- Solution: Carbide stator + matched rotor service

- Benefit: Consistent power section performance over 1,500m laterals

✅ Long-tail keywords embedded:

“carbide stator for UAE Khuff gas drilling”,

“solid stator for Saudi Unayzah sandstone formation”,

“high-temperature mud motor stator for Oman HPHT well”

Compatibility & Rotor Matching

We provide full rotor-stator matching services:

- Standard Fits: For Dyna-Drill, Smith, Baker Hughes, Halliburton, Weatherford motors

- Custom Helix: Reverse-engineered from your worn stator or drawing

- Rotor Reconditioning: We refurbish or manufacture matched rotors in nitrided 4140 or carbide-coated

Just provide:

- Motor series and stage count

- Rotor dimensions or part number

- Drilling parameters (T, P, RPM, fluid)

We deliver a drop-in carbide stator with performance guarantee.

Performance Comparison: Carbide vs. Elastomer

Life in Sandy Well | 10–30 hours | 100–200+ hours |

Max Temperature | 120–150°C | 500°C |

Fluid Compatibility | Limited (swells in OBM) | Universal (inert) |

Torque Consistency | Degrades with wear | Stable for full life |

Cost per Meter Drilled | High | 30–50% lower |

Field data from an ADNOC well: 2.8x ROP increase and zero stator failures over 3 wells using carbide stators.

Why Qalalam? Built for Middle East Drilling Realities

- UAE-based carbide machining and metrology

- In-house helix scanning and CMM validation

- Field-tested in Khuff, Arab, and Unayzah formations

- Next-day delivery of common sizes (4-3/4″, 6-1/2″, 7-7/8″ OD)

We don’t just sell stators—we keep your bit turning when sand tries to stop it.

Frequently Asked Questions (FAQs)

Q1: Can a carbide stator work with a standard steel rotor?

A: Yes—but not optimally. We recommend our matched rotor service:

- Nitrided 4140 rotors for general use

- Carbide-coated rotors for extreme abrasion

This ensures proper clearance (0.1–0.3mm) and maximizes life.

Q2: Is the carbide stator brittle? Will it crack under impact?

A: Not if designed correctly. Our stators use:

- Graded cobalt content (10% at core, 8% at surface)

- Stress-relief annealing

- Optimized lobe thickness

In 2+ years of GCC service, zero field failures from cracking.

Q3: What’s the lead time for a custom carbide stator?

A: 10–12 days from Dubai. We keep common sizes (4-3/4″ to 7-7/8″) in semi-finished stock—final helix grinding takes 5 days.

Q4: Do you provide performance data or run reports?

A: Yes. With every stator, we provide:

- Material Test Report (MTR)

- Helix geometry certificate

- Field run report (on request, from partner rigs)

Q5: Can carbide stators be used in directional drilling with high build rates?

A: Yes—better than elastomer. Carbide maintains consistent power section stiffness, improving toolface control and reducing stall events.

Q6: How does the cost compare to elastomer stators?

A: 3–4x higher upfront—but 50–70% lower cost per meter drilled due to:

- Longer life

- Fewer trips

- Higher ROP

Most operators see ROI in 1–2 wells.

Q7: Are your stators API-compliant?

A: While API doesn’t cover carbide stators, our materials and testing exceed API 7-2 and ISO 10423 for downhole tools. We provide full compliance documentation for operator approval.

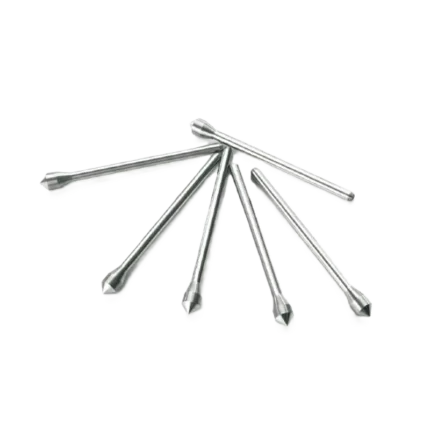

High-wear resistance alloy stator used in wireless measurement-while-drilling tools. Available in multiple diameters per model.

| 🔧 1. Carbide Stator | ||

| Model Code | Sizes D (mm) | Note |

| 3.44″ | 56.6, 69.9, 75.7 | Two or three specs per model |

| 4.125″ | 75.2, 86.4 | Two or three specs per model |

| 5.25″ | 86.4, 94.7, 116.3 | Two or three specs per model |

Reviews

There are no reviews yet.