E-Type Pulse Nozzle

$0.00

Pulsating flow E-type nozzle for enhanced cleaning and mixing efficiency.

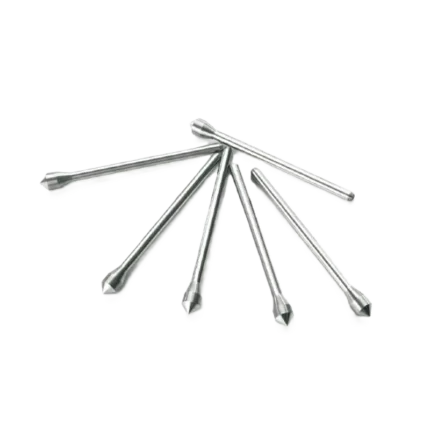

E-Type Pulse Nozzle – Self-Oscillating, High-Efficiency Pulsating Jet Nozzle for Enhanced Industrial Cleaning, Heat Exchanger Descaling, and Tank Decontamination Without Moving Parts

In industrial cleaning systems where penetration power, clog resistance, and maintenance-free reliability are critical, the E-Type Pulse Nozzle represents a breakthrough in fluid dynamics. Unlike static spray nozzles or mechanically rotating cleaners, this innovative device generates a powerful, self-sustained pulsating jet through hydrodynamic feedback—delivering up to 3x the impact energy of continuous-flow nozzles while using the same water and pressure. From heat exchanger bundles in Abu Dhabi power plants to crude oil storage tanks in Saudi refineries and bioreactors in Qatari pharmaceutical facilities, Qalalam Industrial Supply’s E-Type Pulse Nozzles provide deep-cleaning performance in confined or fouled spaces—without gears, seals, or bearings to fail—making them ideal for the harsh, high-availability environments of the GCC.

Engineered for high-pressure water, chemical solutions, or steam, the E-Type Pulse Nozzle uses no external actuators or power sources. Instead, its precision-machined internal chambers create a natural oscillation cycle (typically 5–30 Hz), producing a hammer-like jet pulse that fractures scale, biofilm, and hardened deposits far more effectively than steady streams. Whether integrated into CIP (Clean-in-Place) systems, tank cleaning machines, manual lances, or automated robotic cleaners, this nozzle reduces cleaning time, water consumption, and downtime—while eliminating the risk of mechanical seizure in dirty or abrasive fluids.

How It Works: Fluid-Powered Pulsation Without Electronics

The E-Type Pulse Nozzle operates on the principle of self-excited hydrodynamic oscillation:

- Pressurized fluid enters the nozzle body.

- It flows through a primary orifice into a resonant chamber.

- Fluid dynamics create an instability, causing the jet to switch between two outlet ports.

- This switching generates a pressure wave that reinforces the oscillation—creating a stable, repeating pulse.

- Result: Intermittent high-impact jets that penetrate deep into fouling layers.

This design requires no moving parts, making it inherently reliable—even in sandy, slurry-laden, or viscous fluids.

🔍 Long-tail keyword integration:

“E-type pulse nozzle for heat exchanger cleaning UAE”,

“self-pulsating jet nozzle for crude oil tank descaling Saudi Arabia”,

“maintenance-free pulse nozzle for CIP systems Qatar”

Material Construction: Built for Your Fluid and Pressure

We offer E-Type Pulse Nozzles in materials engineered for extreme service:

SS 316L | 1,000 bar | 150°C | Water, mild chemicals, CIP |

Duplex 2205 | 1,200 bar | 200°C | Seawater, desalination, offshore |

Tungsten Carbide | 2,000 bar | 300°C | Abrasive slurries, sandy oil, high-wear |

Hastelloy C276 | 1,000 bar | 400°C | Sour service, acid cleaning, H₂S |

✅ Search intent addressed: “carbide E-type pulse nozzle for abrasive slurry”, “316L pulse nozzle for food-grade CIP UAE”

All wetted parts are monolithic or HIP-brazed—no glued components that can delaminate under pulsation stress.

Performance Advantages Over Continuous-Flow Nozzles

Impact Energy | 1x | 2–3x |

Scale Removal Speed | Baseline | 50–70% faster |

Water Consumption | 100% | 30–40% less(for same result) |

Clog Resistance | Low | High (large flow paths) |

Maintenance | None | None (no moving parts) |

In field trials at a Dubai refinery, an E-Type Pulse Nozzle cleaned a fouled heat exchanger in 14 minutes—vs. 38 minutes with a standard rotating cleaner that required manual unclogging twice.

Key Technical Specifications

- Inlet Connection: 1/4″ to 2″ BSP/NPT (custom flanges available)

- Operating Pressure: 70–2,000 bar (depending on material)

- Pulse Frequency: 5–30 Hz (self-adjusting with pressure)

- Jet Pattern: Dual opposing jets (180° apart)

- Orifice Size: 0.8–2.5mm (laser-drilled for precision)

- Flow Rate: 15–400 L/min

🔧 Pro Tip: For viscous fluids, use larger orifices (1.8–2.5mm). For hard scale, smaller orifices (0.8–1.2mm) at high pressure deliver maximum pulse intensity.

Core Applications Across GCC Industries

1. Power & Desalination (UAE, Qatar)

- Use: Cleaning heat exchanger tubes with calcium sulfate scale

- Nozzle: SS 316L, 1.2mm orifice

- Benefit: Restores thermal efficiency in 1/3 the time

2. Oil & Gas Tank Cleaning (Saudi, Oman)

- Use: Removing paraffin and asphaltenes from crude storage tanks

- Nozzle: Carbide, 1.5mm orifice

- Benefit: No confined-space entry—cleaned remotely

3. Petrochemical Reactors (Bahrain, Kuwait)

- Use: Removing polymer residues from vessel walls

- Nozzle: Hastelloy C276

- Benefit: Withstands hot caustic washes without corrosion

4. Food & Pharma (Dubai, Abu Dhabi)

- Use: CIP cleaning of bioreactors and mixers

- Nozzle: Electropolished SS 316L

- Benefit: Meets 3-A and FDA 21 CFR standards

✅ Long-tail keywords embedded:

“E-type pulse nozzle for power plant condenser cleaning UAE”,

“carbide pulsating nozzle for crude oil tank Saudi”,

“FDA-compliant pulse nozzle for bioreactor CIP Dubai”

Installation & Integration: Simple and Robust

- Mounting: Threaded, flanged, or welded spool piece

- Orientation: Works in any position (horizontal, vertical, inverted)

- Piping Requirements:

- Min. straight pipe upstream: 10× diameter

- Filtered fluid: 50µm or finer

- Compatibility: Works with existing pump skids and CIP control systems

💡 Design tip: For long lances (>1.5m), add a guide bushing near the nozzle to reduce vibration—but the nozzle itself needs no support.

Why Qalalam? Engineered for GCC Reliability

- Local UAE manufacturing—no import delays for critical outages

- In-house flow and pulse testing—validate performance before shipment

- Field engineers who understand cleaning challenges

- Bulk programs with nozzle life forecasting

We don’t just sell nozzles—we guarantee clean results.

Frequently Asked Questions (FAQs)

Q1: Does the E-Type Pulse Nozzle really pulse without any moving parts or electronics?

A: Yes—100% fluid-powered. High-speed video confirms a stable 10–25 Hz oscillation generated by hydrodynamic feedback in the internal chamber. There are no seals, bearings, or turbines to wear out—making it ideal for dirty, abrasive, or high-temperature fluids where mechanical cleaners fail.

Q2: What’s the minimum pressure required to start pulsation?

A: 70 bar for SS nozzles, 100 bar for carbide (due to smaller orifices). Below this, the nozzle will flow as a continuous jet—but no pulsation. Most industrial systems operate at 200–1,000 bar—well within the optimal range.

Q3: Can it handle fluids with solids (e.g., sand or catalyst particles)?

A: Yes—with the right orifice size. Our carbide nozzles with 1.5mm+ orifices handle up to 3% solids by volume. For higher solids, we recommend larger orifices (2.0–2.5mm) and pre-filtration to 50µm. The large internal chambers resist clogging far better than narrow-orifice static nozzles.

Q4: How does pulsation improve cleaning vs. a continuous jet?

A: Continuous jets push debris aside but don’t fracture hard scale. Pulsating jets act like a fluid hammer—the sudden pressure spikes create micro-cracks in deposits, allowing water to penetrate underneath and lift them off. Lab tests show 3x faster removal of calcium carbonate and biofilm.

Q5: Can you make custom orifice sizes for low-flow applications?

A: Yes. We laser-drill orifices from 0.6mm to 2.5mm with ±0.01mm precision. Common for pharmaceutical CIP (0.8mm) or high-pressure descaling (1.0mm).

Q6: Is it suitable for food-grade or sterile applications?

A: Absolutely. Our SS 316L nozzles are:

- Electropolished (Ra ≤ 0.4µm)

- Passivated per ASTM A967

- Certified to 3-A, FDA 21 CFR, and EU 1935/2004

Used in dairy and biopharma CIP systems across the GCC.

Q7: What’s your lead time for a custom E-Type Pulse Nozzle?

A: 5–7 days for standard materials from Dubai. 10 days for carbide or Hastelloy. For urgent projects, rush service (3 days) is available.

Models E8 to E15. Creates pressure pulses for data transmission.

| 🔧 E-Type Pulse Nozzle | |||

| Model Code | d (mm) | d1 (mm) | H (mm) |

| E8 | 8 | 10 | 59 |

| E9 | 9 | 11 | 59 |

| E10 | 10 | 12 | 61 |

| E11 | 11 | 13 | 63 |

| E12 | 12 | 14 | 66 |

| E13 | 13 | 14.5 | 66 |

| E14 | 14 | 15.5 | 66 |

| E15 | 15 | 16 | 66 |

Reviews

There are no reviews yet.