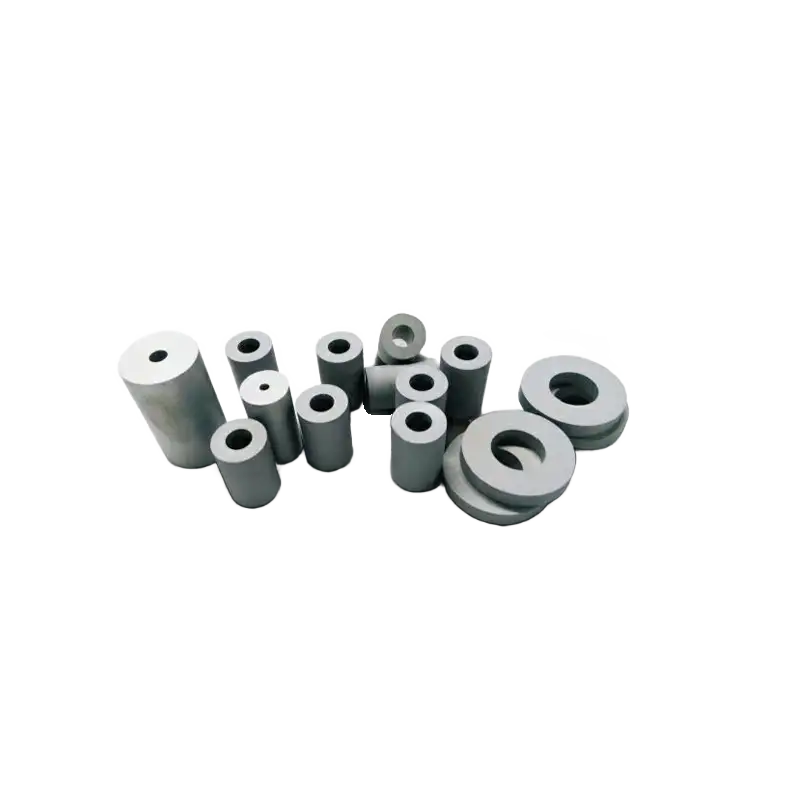

Powder Compacting & Cold Heading Dies

$0.00

High-strength carbide dies for metal powder compaction and cold forming processes.

Powder Compacting & Cold Heading Dies – High-Toughness Cemented Carbide Dies for Precision Metal Forming, Fastener Production, and Powder Metallurgy

In the high-pressure world of metal forming and powder metallurgy, where forces exceeding 2,000 MPa compress, shape, and densify metal at room temperature, the performance of every component begins and ends with one critical element: the die. Powder Compacting & Cold Heading Dies are not passive cavities—they are active engineering components that must resist galling, cracking, wear, and plastic deformation over millions of cycles, while maintaining micron-level dimensional accuracy. From fastener factories in Dubai to automotive powder metal plants in Saudi Arabia and aerospace component forgers in Qatar, Qalalam Industrial Supply delivers ultra-tough, fine-grained tungsten carbide dies engineered for maximum life, minimal downtime, and consistent part quality in the most demanding cold-forming applications across the GCC.

Unlike standard tool steel or low-grade carbide, our dies leverage advanced microalloying, hot isostatic pressing (HIP), and precision EDM finishing to achieve a unique balance of hardness, transverse rupture strength (TRS), and anti-galling properties—ensuring they withstand the extreme compressive and shear stresses of cold heading, powder compaction, and impact extrusion without failure. Whether you’re producing M12 bolts at 120 ppm, gears for electric vehicle motors, or porous oil-impregnated bearings, our dies deliver the reliability and precision your high-volume production demands.

Two Disciplines, One Material Science Foundation

Though used in different processes, both applications share core requirements—and our dies are engineered accordingly:

1. Powder Compacting Dies – For Sintered Metal Parts

Used in hydraulic or mechanical presses to compress metal powder (iron, copper, stainless) into green compacts. Key challenges:

- Abrasive wear from hard powder particles

- Corrosion from lubricant additives

- Radial cracking from uneven ejection forces

→ Our solution: Fine-grain carbide (0.5–0.8µm) with 8–9% cobalt + 0.5% Cr₃C₂ for wear and corrosion resistance. Inner bores are mirror-finished (Ra ≤ 0.2µm) to reduce ejection force.

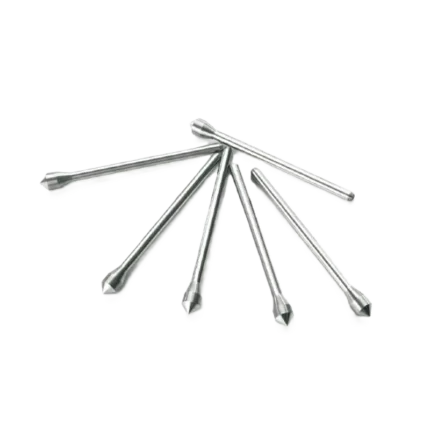

2. Cold Heading Dies – For Fasteners, Rivets, and Cold-Formed Parts

Used in high-speed header machines (e.g., National, Sacmi, Fuki) to plastically deform wire into complex shapes (bolts, screws, nuts). Key challenges:

- Galling from adhesion of workpiece material (e.g., low-carbon steel)

- Impact fatigue from 200+ strokes/minute

- Cone cracking at the die entrance

→ Our solution: Bimodal microstructure (fine + coarse grains) with 10–12% cobalt for toughness, and TiC/NbC additives to inhibit material transfer. Die entrances are precision-chamfered to guide wire without scraping.

🔍 Long-tail keyword integration:

“carbide powder compacting dies for automotive gears UAE”,

“high-TRS cold heading dies for M12 bolts Saudi Arabia”,

“anti-galling carbide header dies for fastener production Qatar”

Material Grades: Engineered for Extreme Load Cycles

We offer specialized grades that go beyond standard ISO classifications:

PCD-8 | 8% | Cr₃C₂ | 3,000 | Powder compacting (general) |

PCD-9C | 9% | Cr₃C₂ + TaC | 2,900 | Corrosive powders (stainless, Cu) |

CHD-11 | 11% | Ni, TaC | 3,200 | Cold heading (medium carbon steel) |

CHD-12T | 12% | TiC + NbC | 3,400 | High-speed heading, high-carbon steel |

✅ Search intent addressed: “best carbide grade for cold heading M10 bolts”, “corrosion-resistant powder die for stainless steel compaction”

All grades undergo HIP treatment to eliminate porosity—the #1 cause of die cracking under cyclic load.

Precision Manufacturing: From Design to Micron Finish

Our die production process ensures zero compromise on performance:

- CAD-Optimized Geometry:

- Taper angles matched to material flow

- Relief zones to reduce stress concentration

- Isostatic Pressing & Sintering:

- Full density, no green cracks

- HIP + Stress Relief:

- 150 MPa Argon, 800°C anneal

- Precision Machining:

- Wire EDM: For complex cavities (±0.005mm)

- Grinding: For cylindrical bores (±0.002mm)

- Lapping: Ra ≤ 0.1µm for critical surfaces

- Quality Control:

- CMM for internal dimensions

- Ultrasonic testing for subsurface flaws

🔧 Why it matters: A 0.01mm bore variation in a powder die causes ±5% density variation in the green compact—leading to sintering cracks.

Core Applications Across GCC Industries

1. Fastener Manufacturing (UAE, Saudi Arabia)

- Use: Cold heading M6–M20 bolts at 90–150 ppm

- Die: CHD-12T, 4-station header set

- Benefit: 2.5x life vs. standard carbide, 30% fewer galling rejects

2. Automotive Powder Metallurgy (Qatar, Oman)

- Use: Compacting synchronizer hubs and VVT rotors

- Die: PCD-8, multi-cavity

- Benefit: Consistent density, zero radial cracks

3. Aerospace & Defense (Bahrain, Dubai)

- Use: Cold forming titanium rivets and Inconel fasteners

- Die: CHD-11 with custom geometry

- Benefit: Meets AMS 4928 and NADCAP audit requirements

4. Electrical Components (Kuwait, UAE)

- Use: Compacting copper contacts and stator cores

- Die: PCD-9C (corrosion-resistant)

- Benefit: No lubricant-induced porosity in sintered parts

✅ Long-tail keywords embedded:

“carbide cold heading dies for bolt manufacturing UAE”,

“powder metal compacting dies for automotive gears Saudi”,

“AMS-compliant carbide header dies for aerospace fasteners Bahrain”

Technical Advantages Over Standard Dies

Porosity | Class C (visible) | Class A (HIP-treated) |

TRS | 2,400–2,600 MPa | 2,900–3,400 MPa |

Galling Resistance | Moderate | Excellent (TiC/NbC) |

Bore Finish | Ra 0.8µm | Ra 0.1–0.2µm |

Life (Cold Heading) | 500k–800k pcs | 1.2M–2M+ pcs |

This translates to:

- Fewer press stoppages

- Higher OEE (Overall Equipment Effectiveness)

- Lower cost per part

Customization: Beyond Catalog Dimensions

We build dies to your exact specifications:

- Cavity Geometry: From simple cylinders to multi-stage, asymmetric forms

- Materials: Iron, copper, stainless, titanium, Inconel

- Tolerances: Down to ±0.001mm for critical aerospace parts

- Marking: Laser-etched serial numbers for lifecycle tracking

- Delivery: 7–10 days for custom dies (UAE-based manufacturing)

💡 Pro Tip: For high-carbon steel heading, we recommend CHD-12T with a 1.5° entrance taper—reduces wire scraping by 40%.

Why Qalalam? Built for High-Volume GCC Industry

- Local design & manufacturing in Dubai—no import delays

- Field engineers who understand header and press mechanics

- Full traceability: MTR with TRS, hardness, porosity class

- Bulk programs: Die sets with predictive replacement scheduling

We don’t just sell dies—we optimize your cold forming economics.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between a powder compacting die and a cold heading die?

A: Powder compacting dies work under pure compression—they must resist abrasive wear from metal powder and allow smooth ejection. Cold heading dies face high-shear, high-impact deformation—they must resist galling (material adhesion) and impact fatigue. Using a powder die in a header causes rapid galling; using a header die in a press leads to abrasive wear. Always match the die to the process.

Q2: Can your dies handle high-speed cold heading (e.g., 150 ppm on a 5-die header)?

A: Yes. Our CHD-12T grade is specifically engineered for high-speed, high-carbon steel heading. In trials with a UAE fastener plant, it lasted 1.8 million cycles at 140 ppm on M10 bolts—3x longer than their previous supplier. Key: TiC/NbC additives prevent galling, even at high temps from friction.

Q3: Do you offer die repair or reconditioning services?

A: Regrinding: yes—if the cavity geometry allows (min. 0.3mm stock). Crack repair: no—carbide cannot be welded. However, we offer exchange programs: return your worn die, get a refurbished one at 60% cost. Most customers find predictive replacement more cost-effective.

Q4: How do I prevent powder die cracking during ejection?

A: Three key steps:

- Use dual-taper design (main bore + relief zone)

- Ensure ejection speed < 100 mm/s

- Apply low-viscosity, non-corrosive lubricant

Our PCD-9C grade includes Cr₃C₂ to resist stress-corrosion cracking from common lubricants.

Q5: Can you make dies for non-standard materials like titanium or Inconel?

A: Absolutely. These materials are galling-prone and work-harden rapidly. We use CHD-11 with custom entrance geometry and polished bores (Ra ≤ 0.1µm). Lead time: 10–12 days. Common in aerospace fastener production in Dubai.

Q6: What’s your lead time for a full header die set (4–6 stations)?

A: 7–10 days from approved drawing. We keep blank carbide preforms in stock—only the final EDM and grinding are custom. For urgent needs, rush service (3–5 days) is available at +25%.

Q7: Do your dies come with certification for automotive or aerospace audits?

A: Yes. Every die includes:

- Material Test Report (MTR) with TRS, hardness, density

- Porosity class (ASTM B962)

- Dimensional inspection report (CMM)

- Traceability to heat number

We comply with IATF 16949 and AS9100 requirements.

Reviews

There are no reviews yet.