Protective Sleeve packing tool

$0.00

Dedicated sleeve for safe installation of mechanical packing.

Protective Sleeve Packing Tool – Reusable Shaft Protection Sleeve for Safe, Damage-Free Installation of Mechanical Packing in Valves and Pumps Across GCC Industrial Facilities

In maintenance operations where shaft scoring, seal damage, and downtime directly impact operational costs, the Protective Sleeve Packing Tool is a simple yet essential device that prevents costly mistakes during routine packing replacement. Designed to slide over pump and valve shafts before compressing mechanical packing, this reusable sleeve acts as a sacrificial barrier between the sharp edges of packing rings and the critical sealing surface of the shaft—ensuring that the original shaft remains untouched during high-force packing installation. From oil refineries in Saudi Arabia and desalination plants in the UAE to chemical processing facilities in Qatar and municipal water stations in Oman, Qalalam Industrial Supply’s Protective Sleeve Packing Tools are engineered for durability, ease of use, and universal compatibility, helping maintenance teams across the GCC reduce shaft replacement costs by up to 70% and extend equipment life significantly.

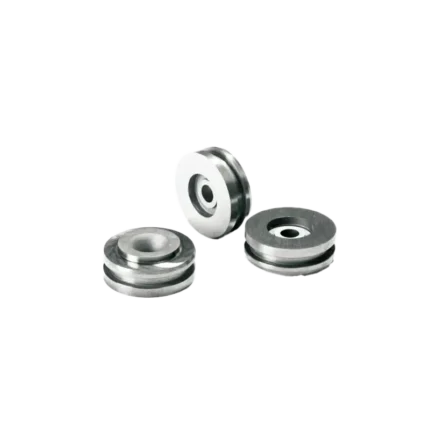

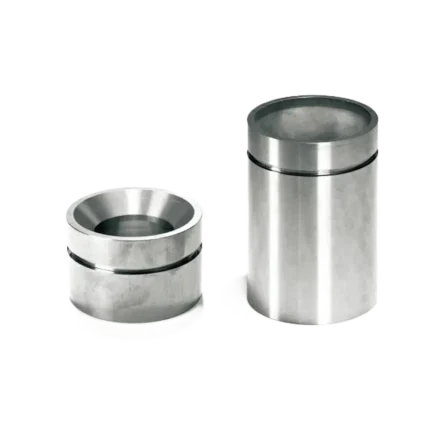

Unlike makeshift solutions like tape or cardboard, our packing sleeves are precision-made from high-strength, low-friction polymers or stainless steel, featuring smooth tapered edges, split or hinged designs for easy installation, and reusable construction for hundreds of packing jobs. Whether used on gate valves, globe valves, centrifugal pumps, or agitators, this tool ensures that every packing change is performed safely, efficiently, and without risk to the shaft—a critical advantage in environments where unplanned downtime costs thousands of dollars per hour.

Why It’s Essential: Preventing the #1 Cause of Shaft Failure

During packing installation, the compression force (often 50–100 Nm with a packing gland wrench) forces the sharp, braided edges of graphite or PTFE packing rings directly against the shaft. Without protection, this causes:

- Micro-grooves and scoring on the shaft surface

- Premature mechanical seal failure (if repurposing the shaft for seals)

- Increased leakage due to uneven packing compression

- Costly shaft replacement or re-machining

The Protective Sleeve Packing Tool eliminates this by absorbing all abrasion and impact—keeping the shaft pristine.

🔍 Long-tail keyword integration:

“protective sleeve packing tool for valve maintenance UAE”,

“reusable shaft protector for pump packing Saudi Arabia”,

“split packing sleeve for gate valve repair Qatar”

Material & Design: Built for Repeated Use

We offer two primary types, each optimized for different needs:

Polymer Sleeve | High-strength PEEK or UHMW-PE | Lightweight, non-marring, chemical-resistant | General industrial, food-grade, light-duty |

Stainless Steel Sleeve | SS 316 with polished edges | Reusable 100+ times, high-temp resistant | Oil & gas, high-pressure, abrasive packing |

Key Design Elements:

- Tapered Leading Edge: Guides packing smoothly over the sleeve

- Split or Hinged Body: Allows installation without disassembly

- Smooth Internal Surface: Ra ≤ 0.8µm to prevent packing snagging

- Reinforced Walls: Resists crushing under gland pressure

✅ Search intent addressed: “best protective sleeve for graphite packing UAE”, “reusable SS 316 packing tool for Saudi refinery”

Both types are non-sparking and compatible with all common packing materials (graphite, PTFE, aramid, carbon).

Technical Specifications

- Shaft Diameter Range: 10mm to 150mm (3/8″ to 6″)

- Length: 50mm to 200mm (standard), custom up to 300mm

- Wall Thickness:

- Polymer: 2–3mm

- Stainless: 1.5–2.5mm

- Temp Resistance:

- Polymer: –50°C to 250°C (PEEK)

- Stainless: –100°C to 600°C

- Reusability:

- Polymer: 20–50 uses

- Stainless: 100+ uses

🔧 Pro Tip: For large shafts (>80mm), use hinged stainless sleeves—they provide maximum rigidity and longevity.

Core Applications Across GCC Industries

1. Oil & Gas Refineries (Saudi Arabia, UAE)

- Use: Packing replacement on high-pressure gate valves

- Tool: SS 316 hinged sleeve, 60mm shaft

- Benefit: Prevents shaft scoring in sour service, avoids $5,000+ shaft replacement

2. Desalination Plants (Qatar, Oman)

- Use: Pump shaft protection during seawater pump maintenance

- Tool: PEEK polymer sleeve, 40mm shaft

- Benefit: Resists chloride exposure, non-contaminating

3. Municipal Water (Dubai, Kuwait)

- Use: Gate valve packing on raw water lines

- Tool: UHMW-PE split sleeve, 30mm shaft

- Benefit: Lightweight and quick for field maintenance crews

4. Chemical Processing (Bahrain, UAE)

- Use: Agitator shaft packing in reactors

- Tool: SS 316 with polished edges

- Benefit: Withstands acidic/alkaline packing and high temps

✅ Long-tail keywords embedded:

“SS 316 protective packing sleeve for Saudi refinery valve”,

“PEEK shaft protector for UAE desalination pump”,

“split packing tool for Dubai municipal gate valve”

Advantages Over DIY Methods

Teflon Tape | High (tears under pressure) | None | Poor |

Cardboard/Plastic | Medium | None | Inconsistent |

No Protection | Very High | — | Shaft ruined |

Qalalam Packing Sleeve | None | 20–100+ uses | Perfect shaft, leak-free packing |

Field feedback from a Kuwait oil facility: “Reduced shaft replacement costs by 75% in one year.”

Why Qalalam? Practical Tools for Real Maintenance

- Local UAE inventory of common sizes (20–80mm shaft)

- Color-coded by size for quick identification

- Bulk kits for maintenance teams (10 sizes in a case)

- Next-day delivery across GCC

We don’t just sell tools—we protect your critical rotating assets.

Frequently Asked Questions (FAQs)

Q1: Can I reuse the protective sleeve?

A: Yes—designed for reuse. Stainless steel sleeves last 100+ installations; polymer lasts 20–50. Inspect for cracks or deformation before reuse—replace if damaged.

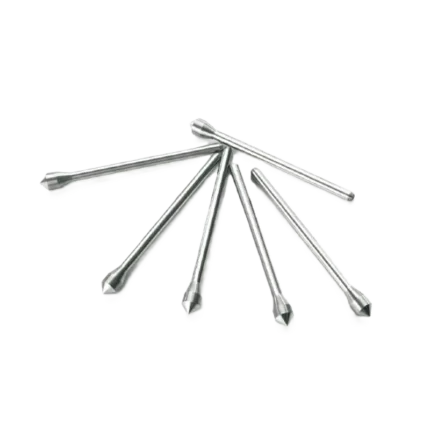

Q2: How do I install a split sleeve without disassembling the pump?

A: Simply open the split, slide it over the shaft at the packing location, and close it around the shaft. No need to remove bearings, impellers, or couplings—ideal for in-situ maintenance.

Q3: Will the sleeve interfere with packing compression?

A: No. The sleeve is slightly shorter than the packing set—it only covers the shaft during compression. Once packing is seated, the sleeve is removed, leaving a pristine shaft beneath intact packing.

Q4: Are your sleeves compatible with all packing types?

A: Yes—tested with:

- Graphite (most abrasive)

- PTFE

- Aramid (Kevlar)

- Carbon fiber

- Ceramic-reinforced

The smooth surface prevents snagging on any fiber.

Q5: Do you offer custom sizes for odd shaft diameters?

A: Yes. We can produce sleeves for any shaft from 8mm to 200mm. Just provide:

- Shaft diameter (±0.1mm)

- Packing length

- Material preference (polymer or SS)

Lead time: 3–5 days.

Q6: Can stainless sleeves be used in food-grade applications?

A: Yes. Our SS 316 sleeves are electropolished and passivated, meeting FDA 21 CFR and 3-A standards for food and pharma use.

Q7: What’s included in your maintenance kit?

A: Our Standard Kit includes:

- 10 split sleeves (20, 25, 30, 35, 40, 50, 60, 70, 80, 100mm)

- Durable storage case

- Usage guide in English & Arabic

Ideal for workshop or field teams.

Reviews

There are no reviews yet.