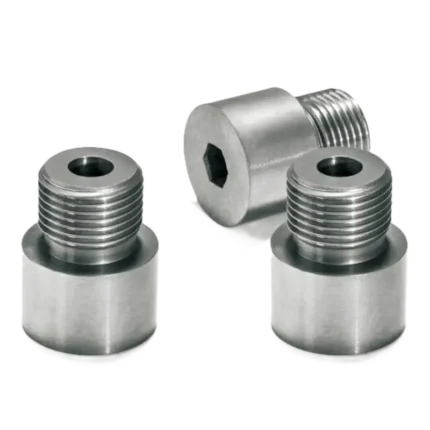

Common Threaded Nozzle

$0.00

Versatile general-purpose threaded nozzle for industrial spraying tasks.

Common Threaded Nozzle – Universal, Cost-Effective Industrial Spray Nozzle for General-Purpose Washdown, Cooling, Humidification, and Process Applications Across GCC Facilities

In industrial environments where simplicity, reliability, and broad compatibility outweigh the need for specialized performance, the Common Threaded Nozzle remains the workhorse of fluid delivery systems. Designed for straightforward installation and consistent operation, this versatile nozzle serves as the go-to solution for equipment washdown, process cooling, dust control, gas conditioning, and humidification in factories, power plants, oilfields, and municipal facilities across the UAE, Saudi Arabia, Qatar, and beyond. At Qalalam Industrial Supply, our Common Threaded Nozzles are manufactured to global dimensional and performance standards, available in brass, stainless steel 316, and tungsten carbide, and engineered to deliver dependable spray performance—without the complexity or cost of custom-engineered systems.

Unlike proprietary or application-specific nozzles, the “Common Threaded” designation refers to a universally recognized design featuring standardized threads (BSP/NPT), simple internal geometry, and moderate spray characteristics—making it ideal for maintenance teams and engineers who need a drop-in replacement that just works. Whether you’re replacing a worn nozzle on a cooling tower in Dubai, setting up a new washdown station in a Riyadh food plant, or maintaining dust suppression lines in an Omani quarry, our Common Threaded Nozzle provides the balance of performance, durability, and affordability that keeps operations running smoothly.

What Makes It “Common”? Design for Universal Use

The Common Threaded Nozzle is defined by its practical, no-frills engineering:

- Simple Full-Cone or Flat-Fan Spray: Reliable coverage for general tasks

- Robust, Open Flow Path: Resists clogging in moderately dirty water

- Standard Threading: Swaps directly into any BSP/NPT port

- Moderate Spray Angles: Typically 60°–80° full cone or 25°–65° flat fan

- Wide Orifice Range: From 0.5mm to 5.0mm for flow flexibility

This design prioritizes ease of use, availability, and service life over extreme performance—making it the backbone of industrial spray systems worldwide.

🔍 Long-tail keyword integration:

“common threaded nozzle for industrial washdown UAE”,

“stainless steel common spray nozzle for food plant Saudi Arabia”,

“brass BSP threaded nozzle for cooling tower Qatar”

Material Selection: Matched to Your Operating Environment

We offer Common Threaded Nozzles in three core materials:

Brass | 30 bar | 120°C | Good (fresh water, air) | General washdown, air nozzles, non-corrosive cooling |

Stainless Steel 316 | 100 bar | 150°C | Excellent | Food-grade, seawater, chemicals, oil & gas, pharma |

Tungsten Carbide | 200 bar | 300°C | Exceptional | Abrasive slurries, sandy water, mining, high-wear zones |

✅ Search intent addressed: “best common nozzle material for seawater washdown”, “carbide threaded nozzle for slurry rinsing UAE”

All nozzles are precision-machined with consistent orifice tolerances (±0.02mm) for repeatable flow.

Spray Patterns & Performance Range

While “common” implies standardization, we offer flexibility:

Full Cone | 60°–80° | 0.8–5.0mm | Cooling towers, gas scrubbing, general washdown |

Flat Fan | 25°–65° | 0.5–3.0mm | Surface cleaning, conveyor rinsing, de-dusting |

Hollow Cone | 60°–90° | 0.8–2.5mm | Humidification, fine misting, gas cooling |

Performance Example (SS 316, 3 bar, 1.5mm orifice):

- Flow: ~2.5 L/min

- Coverage: ~800mm diameter at 500mm distance

- Drop size: 250–600 microns

🔧 Pro Tip: For food plant washdown, use SS 316 flat fan (50°)—provides even coverage without pooling.

Thread Standards: Plug-and-Play Compatibility

Our nozzles use globally accepted threads for instant integration:

- BSP (British Standard Pipe): 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″

→ Most common in GCC, Europe, and Middle East - NPT (National Pipe Taper): 1/8″ to 1″

→ Standard in US-sourced equipment - Metric: M12×1.5 to M24×2 (on request)

Each nozzle features a smooth sealing face—ensures leak-free installation with standard PTFE tape or O-rings.

Core Applications Across GCC Industries

1. Food & Beverage Processing (UAE, Saudi)

- Use: Sanitary washdown of conveyors, tanks, and mixers

- Nozzle: SS 316, 1/2″ BSP, flat fan

- Benefit: Meets FDA 21 CFR, 3-A, and GSO standards

2. Oil & Gas Facilities (Qatar, Oman)

- Use: Equipment washdown, deck cleaning, firewater backup

- Nozzle: SS 316 or brass, 3/4″ BSP, full cone

- Benefit: Resists salt air and mild hydrocarbons

3. Power & Desalination (Kuwait, Bahrain)

- Use: Cooling tower distribution, condenser rinsing

- Nozzle: Brass or SS 316, 1/2″ BSP

- Benefit: Uniform water distribution, prevents scaling

4. Construction & Mining (Saudi, UAE)

- Use: Dust suppression on stockpiles and roads

- Nozzle: Brass, 1″ BSP, full cone

- Benefit: Reduces PM10 emissions, complies with local EPA

✅ Long-tail keywords embedded:

“SS 316 common threaded nozzle for UAE food plant washdown”,

“brass BSP nozzle for Saudi oilfield deck cleaning”,

“1/2 inch common spray nozzle for Qatar cooling tower”

Why Choose Common Over Specialized Nozzles?

Budget-Constrained Projects | High cost | Low cost, high value |

General Maintenance | Over-engineered | “Good enough” reliability |

Multi-Application Sites | Requires inventory of many types | One nozzle fits many uses |

Emergency Replacements | Long lead time | Always in stock, next-day delivery |

Field feedback from a Dubai industrial park: “We keep only Common Threaded SS 316 in stock—covers 90% of our needs.”

Why Qalalam? Your Local Source for Universal Reliability

- UAE warehouse stock of all standard sizes (1/8″ to 1″ BSP/NPT)

- Material-certified (MTR for SS and carbide)

- Bulk discounts for municipal and industrial contracts

- Next-day delivery across GCC

We don’t just sell nozzles—we keep your basic systems running without fuss.

Frequently Asked Questions (FAQs)

Q1: What makes a nozzle “common threaded” vs. just “threaded”?

A: “Common Threaded” refers to a standardized design used across industries—not proprietary. It has:

- Predictable spray performance

- Standard thread types (BSP/NPT)

- Widely available replacement

In contrast, “threaded” could mean any custom nozzle. Our “Common” line ensures interchangeability with major brands (Spraying Systems, Lechler, etc.).

Q2: Can I use a brass common nozzle in a food plant?

A: Only if not in direct contact with food. Brass contains lead and is not FDA-compliant for food zones. For food contact, use SS 316 (certified to FDA 21 CFR). For non-contact washdown (e.g., floors, walls), brass is acceptable.

Q3: How do I choose between full cone and flat fan?

A:

- Full Cone: For 3D coverage (cooling towers, gas scrubbing)

- Flat Fan: For 2D surface cleaning (conveyors, walls, decks)

When in doubt, flat fan is more versatile for washdown.

Q4: Are your nozzles compatible with firewater or deluge systems?

A: Yes—our brass and SS 316 nozzles meet NFPA and FM Global requirements for deluge systems. Use ≥3/4″ thread and ≥3.0mm orifice for adequate flow.

Q5: Do you offer common nozzles in plastic (e.g., PP, PVDF)?

A: Yes—for high-purity or extreme corrosion (e.g., hydrofluoric acid). We supply PP, PVDF, and PTFE common nozzles on request. Lead time: 7–10 days.

Q6: What’s the expected life of a brass nozzle in tap water?

A: 2–3 years in clean tap water at <30°C. In hot or chlorinated water, 6–12 months. For longer life, upgrade to SS 316.

Q7: Can you laser-mark nozzles with size or your logo?

A: Yes. We offer permanent laser engraving of:

- Orifice size (e.g., “1.5”)

- Material code (“316”)

- Your company logo or part number

Ideal for inventory control in large facilities.

Models SP08 to SP22. Sizes from 6.35 mm to 17.46 mm.

| 🔧 33. Common Threaded Nozzle | |

| Model Code | Size d (mm) |

| SP08 | 6.35 |

| SP09 | 7.14 |

| SP10 | 7.93 |

| SP11 | 8.74 |

| SP12 | 9.53 |

| SP13 | 10.32 |

| SP14 | 11.11 |

| SP15 | 11.91 |

| SP16 | 12.7 |

| SP17 | 13.49 |

| SP18 | 14.29 |

| SP19 | 15.08 |

| SP20 | 15.88 |

| SP21 | 16.67 |

| SP22 | 17.46 |

Reviews

There are no reviews yet.