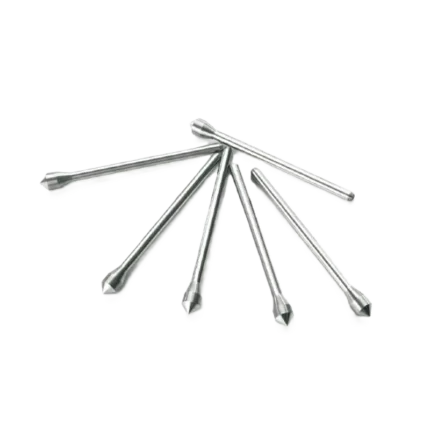

Flow Orifice Plate

$0.00

Precision orifice plates for flow measurement and pressure control in piping systems.

Flow Orifice Plate – Precision-Machined Carbide and Stainless Steel Orifice Plates for Accurate Flow Measurement, Pressure Control, and Safety Systems in Oil, Gas, Water, and Industrial Process Lines

In fluid handling systems across the GCC—where accurate flow data drives billing, safety, and process efficiency—the Flow Orifice Plate is not a simple hole in metal, but a calibrated flow restriction device engineered to ISO 5167 and AGA 3 standards. From custody transfer stations in Abu Dhabi oilfields to desalination plants in Jubail and district cooling networks in Dubai, our Flow Orifice Plates deliver repeatable differential pressure (ΔP) signals, long-term dimensional stability, and resistance to erosion in abrasive or corrosive media—ensuring your flow meters stay within calibration for years, not months. At Qalalam Industrial Supply, we manufacture high-precision orifice plates in stainless steel, duplex, and tungsten carbide, using metrology-grade machining and rigorous testing to meet the exacting demands of oil & gas, water treatment, power, and chemical processing industries across the Middle East.

Unlike stamped or laser-cut plates that suffer from burrs, tapered edges, or inconsistent bore geometry, our Flow Orifice Plates are precision-ground, edge-honed, and fully certified—ensuring the β-ratio (bore-to-pipe ratio) and upstream/downstream edge sharpness meet international standards for ±0.5% flow accuracy. Whether used for fiscal metering, pump protection, leak detection, or safety relief, our plates provide the reliability and traceability your critical operations require.

Why Precision Matters: The Physics of Orifice Flow

Orifice-based flow measurement relies on Bernoulli’s principle: a known restriction creates a predictable pressure drop proportional to the square of flow rate. But this only works if:

- The bore is perfectly round (no ovality)

- The upstream edge is sharp and square (no radius > 0.0004× bore)

- The surface finish is smooth (Ra ≤ 0.8µm) to prevent flow separation

- The material resists erosion—especially in sandy oil or seawater

A poorly made plate introduces systematic errors that compound over time—leading to under-billing, over-pressurization, or false safety trips.

🔍 Long-tail keyword integration:

“ISO 5167 flow orifice plate for oil custody transfer UAE”,

“carbide orifice plate for seawater desalination Saudi Arabia”,

“duplex stainless orifice plate for district cooling Dubai”

Material Selection: Matching Corrosion Resistance to Fluid

We offer Flow Orifice Plates in materials engineered for your specific media:

SS 316L | Excellent corrosion resistance, non-magnetic | Water, mild chemicals, district cooling |

Duplex 2205 | High strength, chloride-resistant | Seawater, desalination, offshore |

Inconel 625 | Resists H₂S, CO₂, high temp | Sour gas, refinery streams |

Tungsten Carbide | Extreme erosion resistance | Sandy oil, slurry, high-velocity gas |

Hastelloy C276 | Resists oxidizing acids | Chemical processing, acid injection |

✅ Search intent addressed: “best orifice plate material for seawater flow measurement”, “carbide orifice plate for sandy crude oil UAE”

All plates include material test reports (MTRs) with chemical composition and mechanical properties.

Design Types: Optimized for Your Installation

We manufacture all standard orifice plate configurations per ISO 5167:

1. Concentric Orifice Plate

- Use: Clean liquids, gases, steam

- Feature: Bore centered in plate

- Accuracy: ±0.5% with proper upstream piping

2. Eccentric Orifice Plate

- Use: Slurries, dirty liquids with solids

- Feature: Bore offset to bottom—solids pass through

- Benefit: Prevents sediment buildup

3. Segmental Orifice Plate

- Use: Heavy slurries, viscous fluids

- Feature: Partial segment cut (like a moon)

- Benefit: Handles high solids loading

4. Quadrant Edge Orifice Plate

- Use: Viscous fluids (e.g., heavy oil, syrups)

- Feature: Rounded upstream edge

- Benefit: Reduces pressure loss vs. sharp edge

🔧 Custom options:

- Integral flow conditioners (for short straight runs)

- Dual orifice plates for wide turndown ratio

- RFID tags for digital calibration records

Precision Manufacturing: Metrology-Grade Accuracy

Our production process ensures certified performance:

- Material Certification: Full MTR for every batch

- CNC Milling & Grinding:

- Bore diameter: ±0.01mm tolerance

- Plate thickness: ±0.05mm

- Edge sharpness: Verified under 50x microscope

- Surface Finish:

- Upstream face: Ra ≤ 0.4µm

- Bore wall: Ra ≤ 0.8µm

- Inspection:

- Optical comparator for edge geometry

- CMM for concentricity and thickness

- Flow calibration (optional, per ISO 4185)

💡 Critical detail: The upstream edge must have zero radius—even 0.1mm rounding causes 2–3% flow error.

Core Applications Across GCC Industries

1. Oil & Gas Custody Transfer (UAE, Saudi, Qatar)

- Use: Fiscal metering of crude oil at export terminals

- Plate: Carbide concentric, ISO 5167 Class A

- Benefit: 5-year calibration stability vs. 6 months for SS in sandy oil

2. Desalination & Water (Oman, Kuwait, UAE)

- Use: Flow measurement in SWRO feed and brine lines

- Plate: Duplex 2205 eccentric

- Benefit: Resists pitting in 45,000 ppm seawater

3. District Cooling (Dubai, Doha)

- Use: Chilled water flow to malls and towers

- Plate: SS 316L concentric

- Benefit: Meets DEWA and Kahramaa specifications

4. Power & Petrochemical (Bahrain, Saudi)

- Use: Steam and chemical injection flow control

- Plate: Inconel 625 quadrant edge

- Benefit: Handles 400°C, 100 bar with zero drift

✅ Long-tail keywords embedded:

“ISO 5167 Class A orifice plate for oil custody UAE”,

“duplex eccentric orifice plate for SWRO desalination”,

“DEWA-approved flow orifice plate for district cooling Dubai”

Technical Certification: Beyond Basic Compliance

Every plate includes:

- ISO 5167 Compliance Certificate

- Material Test Report (MTR)

- Dimensional Inspection Report (with CMM data)

- Marking: Laser-etched with:

- Bore size

- Pipe size

- Material

- Serial number

- Date of manufacture

For custody transfer, we provide witnessed calibration at accredited labs.

Why Qalalam? Built for GCC Process Integrity

- Local UAE manufacturing—no 8-week import delays for critical projects

- In-house metrology lab—CMM, optical comparator, profilometer

- Engineers fluent in AGA, ISO, and DEWA standards

- Bulk pricing with JIT delivery for EPC contractors

We don’t just sell orifice plates—we protect your flow data integrity.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between a standard orifice plate and an ISO 5167 Class A plate?

A: ISO 5167 Class A is the highest accuracy grade—requiring:

- Bore tolerance: ±0.01mm

- Edge sharpness: < 0.0004× bore radius

- Surface finish: Ra ≤ 0.4µm

- Full metrology report

Standard plates (often stamped) have ±0.1mm tolerance and rounded edges—causing 3–5% flow error. For custody transfer or safety systems, only Class A is acceptable.

Q2: Can you make orifice plates for non-standard pipe sizes (e.g., 14-inch or 22-inch)?

A: Yes. We manufacture plates from ½” to 48” pipe sizes. For odd sizes (e.g., 14”), we follow ASME B16.36 or custom flange specs. Just provide your flange standard (e.g., ASME B16.5, DIN, JIS) and pressure class.

Q3: How do I know if I need concentric, eccentric, or segmental?

A:

- Concentric: Clean fluids (water, gas, light oil)

- Eccentric: Liquids with <10% solids (e.g., wastewater, crude with sand)

- Segmental: Heavy slurries (>10% solids, e.g., mining tailings)

When in doubt, send a fluid sample or P&ID—our engineers will recommend the best type.

Q4: Do your carbide orifice plates crack under thermal cycling?

A: No. We use graded carbide-to-steel transition designs or full-carbide plates with thermal expansion matching. In Saudi oilfields, our carbide plates handle 80°C to 120°C cycles daily with zero cracking. Tip: Avoid sudden quenching—allow gradual cooldown.

Q5: Can you add pressure taps (corner, flange, D&D½) to the plate?

A: The plate itself doesn’t include taps—taps are in the flanges or piping. But we design the plate to match any tap configuration. Just specify:

- Tap type: Corner, flange, radius, D&D½

- Tap location: Upstream/downstream distance

We ensure the plate doesn’t interfere with tap placement.

Q6: What’s your lead time for a certified orifice plate?

A: 5–7 days for standard materials (SS 316, duplex) from Dubai. 10–12 days for carbide or Inconel. For urgent projects, rush service (3 days) is available.

Q7: Do you offer recalibration or recertification services?

A: Yes. We provide:

- Visual inspection for erosion/corrosion

- Re-measurement of bore diameter

- Updated certification

Most plates last 5+ years in clean service—but in abrasive media, annual inspection is recommended.

Reviews

There are no reviews yet.