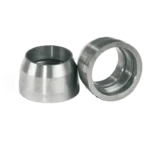

Lift Valve (Mushroom Head)

$0.00

Mushroom-style lift valve for high-flow, low-crack pressure applications.

Lift Valve (Mushroom Head) – High-Flow, Low-Crack Pressure Relief and Check Valve Element for Steam, Water, and Industrial Process Systems Across the GCC

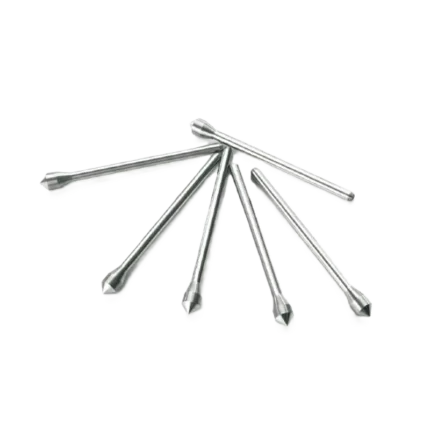

In fluid systems requiring rapid flow response, bubble-tight shut-off, and reliable pressure relief, the Lift Valve (Mushroom Head)—also known as a poppet valve or mushroom valve—delivers superior performance through its distinctive mushroom-shaped disc and guided stem design. Unlike flat or ball check valves, the mushroom head provides a large flow area, smooth flow path, and low cracking pressure, making it ideal for boiler safety valves, condensate return systems, hydraulic relief circuits, and high-flow check applications in power plants, refineries, desalination facilities, and district cooling networks across Saudi Arabia, the UAE, Qatar, and Oman. At Qalalam Industrial Supply, our Lift Valves are precision-machined from stainless steel 316, Stellite-faced alloys, or Inconel 625, featuring aerodynamic contours, mirror-finish sealing surfaces (Ra ≤ 0.2 µm), and thermal-stable geometry—ensuring fast opening, positive seating, and long-term reliability in high-cycle, high-temperature, and high-pressure service.

Whether used as a relief element in safety valves, a non-return check in pump discharge lines, or a modulating element in control valves, our Mushroom Head Lift Valves provide the flow efficiency, sealing integrity, and erosion resistance demanded by critical industrial processes in the Middle East.

Why Mushroom Head? The Hydrodynamics of Efficient Flow

The mushroom-shaped disc is engineered to optimize fluid dynamics:

- Large Flow Area: The domed head lifts cleanly off the seat, minimizing flow restriction

- Low Cracking Pressure: Requires minimal differential pressure to open (as low as 0.5 bar)

- Stable Seating: Self-centering design ensures repeatable, chatter-free closure

- Erosion Resistance: Rounded profile reduces turbulence and cavitation damage

This makes it superior to ball or disc check valves in high-flow, low-pressure-drop applications.

🔍 Long-tail keyword integration:

“mushroom head lift valve for boiler safety UAE”,

“Stellite-faced poppet valve for Saudi condensate return”,

“low-crack pressure lift valve for Qatar district cooling”

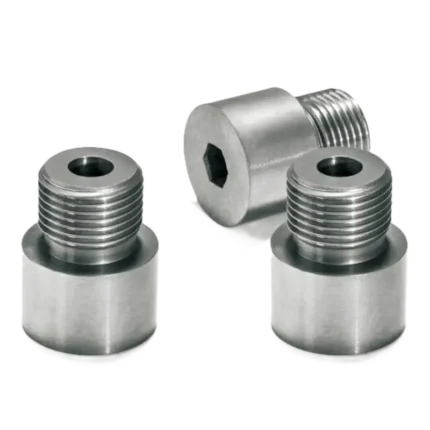

Material & Facing Options: Built for Your Service

We offer Lift Valves in materials matched to your fluid and temperature:

SS 316 | Precision ground | HRC 25 | 200°C | Water, steam, general industrial |

SS 316 | Stellite 6 overlay | 40–45 HRC | 400°C | High-temp steam, moderate abrasion |

Inconel 625 | Stellite 21 overlay | 38–42 HRC | 700°C | Sour gas, high-temp relief, chemical |

Tungsten Carbide | Full carbide | 88–92 HRA | 500°C | Abrasive slurry, sand-laden service |

✅ Search intent addressed: “best lift valve material for steam boiler UAE”, “Stellite mushroom valve for Saudi high-temp service”

All hard-facing is applied via precision PTA welding for metallurgical bonding and zero porosity.

Key Technical Features

- Sealing Surface:

- Flat or conical seat (per API 527)

- Ra ≤ 0.2 µm (standard), Ra ≤ 0.05 µm (for metal seats)

- Stem Guidance:

- Precision bushing or cage to prevent tilting

- Radial clearance: 0.05–0.10mm (prevents binding)

- Flow Coefficient (Cv): Up to 3x higher than ball check valves of same size

- Cracking Pressure: Adjustable via spring preload (0.5–10 bar typical)

🔧 Pro Tip: For high-cycle service (>100,000 cycles), specify Stellite-facing + guided stem to prevent seat erosion and chatter.

Core Applications Across GCC Industries

1. Power & Desalination (UAE, Qatar)

- Use: Boiler safety relief and condensate return check valves

- Valve: SS 316 + Stellite 6, 2″ size

- Benefit: Handles 200 bar, 300°C, meets ASME Section I

2. Oil & Gas Refining (Saudi Arabia, Kuwait)

- Use: High-pressure letdown and flare system relief

- Valve: Inconel 625 + Stellite 21

- Benefit: Resists H₂S and thermal cycling, meets API 520/521

3. District Cooling (Dubai, Abu Dhabi)

- Use: Pump discharge non-return valves

- Valve: SS 316, low-crack design

- Benefit: Prevents water hammer, reduces energy loss

4. Chemical Processing (Oman, Bahrain)

- Use: Reactor pressure relief and backflow prevention

- Valve: Carbide-faced SS 316

- Benefit: Withstands abrasive catalyst slurry

✅ Long-tail keywords embedded:

“Stellite mushroom lift valve for UAE boiler safety”,

“Inconel 625 poppet valve for Saudi flare system”,

“low-crack lift check valve for Dubai district cooling”

Performance Advantages Over Ball Check Valves

Flow Area | Restricted by ball size | Full port, minimal obstruction |

Cracking Pressure | High (2–5 bar) | Low (0.5–2 bar) |

Chatter Risk | High (ball bounce) | Low (guided, stable seating) |

Erosion Resistance | Poor (point contact) | Excellent (broad sealing surface) |

Maintenance | Frequent (seat wear) | Low (long-life facing) |

Field data from a Riyadh power plant: Zero valve chatter failures after replacing ball checks with mushroom lift valves in feedwater lines.

Why Qalalam? Precision for Critical Service

- UAE-based PTA welding and lapping

- In-house flow and pressure testing

- Full material traceability (MTR with every order)

- ASME, API, and ISO compliance documentation

- Next-day delivery of common sizes (1/2″ to 4″)

We don’t just sell valves—we ensure your relief and check systems respond reliably, every time.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between a lift valve and a ball check valve?

A: A ball check uses a spherical element—simple but prone to chatter, high cracking pressure, and erosion. A Lift Valve (Mushroom Head) uses a guided, domed disc—providing larger flow area, lower cracking pressure, and stable seating—ideal for high-flow, high-cycle applications like boilers and pumps.

Q2: Can I adjust the cracking pressure?

A: Yes—in spring-loaded designs, cracking pressure is set by:

- Spring rate

- Preload adjustment

We can calibrate to your exact requirement (e.g., 1.2 bar ±0.1).

Q3: Do your lift valves meet ASME Section I for boilers?

A: Yes. Our Stellite-faced SS 316 valves comply with:

- ASME BPVC Section I (Power Boilers)

- API 527 (Seat tightness)

- ISO 5208 (Leakage classes)

We provide certificates with every order.

Q4: Are carbide-faced lift valves suitable for clean steam service?

A: Overkill. For clean steam, Stellite 6 is more cost-effective. Carbide is reserved for abrasive slurries or sand-laden fluids.

Q5: Can you supply valves with guided stems for vertical mounting?

A: Yes. All our lift valves include precision stem guidance (bushing or cage) to prevent tilting and leakage—critical in vertical or high-vibration installations.

Q6: What’s your lead time for Inconel lift valves?

A: 10–12 days from Dubai. We keep SS 316 and Stellite-faced in stock for 5–7 day delivery.

Q7: Do you offer refurbishment of worn lift valves?

A: Yes. Our service includes:

- Crack inspection

- Re-facing with Stellite or carbide

- Precision grinding and lapping

Cost: 50% of new, with same performance guarantee.

Reviews

There are no reviews yet.