Main Valve Core

$0.00

Primary flow control element in high-pressure industrial valves.

Main Valve Core – High-Performance Flow Control Element for Critical Shut-Off, Modulation, and Safety Service in Oil & Gas, Power, and Process Valves Across the GCC

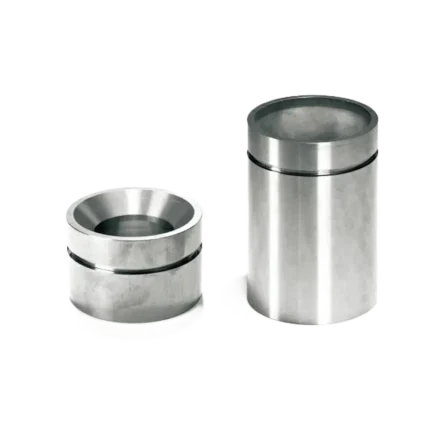

In mission-critical fluid systems—where bubble-tight shut-off, erosion resistance, and long-term reliability directly impact safety, environmental compliance, and operational continuity—the Main Valve Core serves as the primary flow-controlling element in gate, globe, and ball valves across the Middle East. Engineered to seal against high-pressure differential while withstanding abrasive slurries, sour gas (H₂S), high-temperature steam, and corrosive chemicals, this precision component is the heart of valves used in Saudi Aramco wellheads, UAE LNG export terminals, Qatari petrochemical reactors, and Omani power plant feedwater systems. At Qalalam Industrial Supply, our Main Valve Cores are manufactured from Stellite-faced stainless steel, tungsten carbide, or Inconel 718, featuring aerodynamically optimized profiles, mirror-finish sealing surfaces (Ra ≤ 0.2 µm), and API 600/602 compliance—ensuring Class VI shut-off, minimal maintenance, and decades of service life in the harshest GCC industrial environments.

Unlike generic plugs or discs, the Main Valve Core is co-engineered with its mating seat to ensure perfect contact, even under thermal cycling and high-cycle operation—making it the ultimate solution for safety shutdown valves, flow control regulators, and fugitive-emission-critical applications where failure is not an option.

Core Functions: Sealing, Flow Control, and Durability

The Main Valve Core performs three mission-critical roles:

- Primary Sealing Surface:

Provides Class IV to Class VI leak-tight shut-off against the valve seat—essential for safety and environmental compliance. - Flow Modulation:

Contoured profiles (linear, equal percentage) enable precise flow control for process stability in refineries and chemical plants. - Wear & Erosion Resistance:

Hard-faced surfaces resist sand, catalyst fines, cavitation, and chemical attack—extending service life by 3–5x vs. standard trim.

Even a 0.5µm surface defect can cause measurable leakage in safety-critical service.

🔍 Long-tail keyword integration:

“Stellite-faced main valve core for Saudi Aramco wellhead”,

“carbide valve plug for UAE LNG export terminal”,

“Inconel 718 main core for Qatar petrochemical reactor”

Material & Facing Options: Engineered for Extreme Service

We offer Main Valve Cores in configurations matched to your fluid and duty:

SS 316/F91 | Stellite 6 overlay | 40–45 HRC | Steam, high-temp, moderate abrasion |

SS 316 | Tungsten Carbide | 88–92 HRA | Slurry, sand, extreme abrasion |

Inconel 718 | Stellite 21 overlay | 38–42 HRC | Sour gas (H₂S), seawater, high-temp |

Duplex 2205 | Nitrided | 60 HRC | Desalination, offshore, chloride service |

✅ Search intent addressed: “best main valve core for sour gas service UAE”, “carbide-faced plug for abrasive slurry Saudi”

All hard-facing is applied via precision PTA (Plasma Transferred Arc) welding—not spraying—for metallurgical bond strength and zero porosity.

Precision Manufacturing: Valve-Grade Accuracy

Our production process ensures certified performance:

- Diameter Tolerance: h6 (±0.009mm for 50mm)

- Roundness: ≤ 0.002mm

- Straightness: ≤ 0.003mm per 100mm

- Surface Finish:

- Sealing surface: Ra ≤ 0.2µm (standard), Ra ≤ 0.05µm (for metal seats)

- Flow-contoured areas: Ra ≤ 0.4µm

- Edge Break: 0.02–0.05mm radius

- Final Inspection:

- CMM for geometry

- Profilometer for surface finish

- Blue match test with mating seat

🔧 Why it matters: In an API 600 Class 900 gate valve, a 0.02mm out-of-round core causes Class II leakage—failing safety audits.

Core Applications Across GCC Industries

1. Oil & Gas Upstream (Saudi Arabia, UAE)

- Use: Main cores in wellhead and Christmas tree valves

- Core: Inconel 718 + Stellite 21

- Benefit: Resists sour gas and sand, meets NACE MR0175

2. LNG & Gas Processing (Qatar, Oman)

- Use: Cryogenic and high-pressure export valves

- Core: SS 316 + Stellite 6, Ra 0.1µm

- Benefit: Maintains sealing at -162°C to 200°C

3. Petrochemical (Kuwait, Bahrain)

- Use: Reactor pressure control valves

- Core: Carbide-faced SS 316

- Benefit: Withstands catalyst slurry abrasion

4. Power Generation (Dubai, Abu Dhabi)

- Use: Boiler feedwater stop-check valves

- Core: F91 + Stellite 6

- Benefit: Handles 200 bar, 300°C with zero erosion

✅ Long-tail keywords embedded:

“NACE-compliant main valve core for Saudi sour gas”,

“cryogenic valve plug for Qatar LNG terminal”,

“carbide main core for Kuwait petrochemical slurry”

OEM Cross-Reference & Replacement

We maintain databases for major valve brands:

- Cameron, Velan, Flowserve, Crane, KSB, Tyco

Just provide:

- Valve model, size, and pressure class

- Service conditions (fluid, T, P)

- Core dimensions or part number

We deliver a direct-fit, upgraded-performance replacement—often with longer life than OEM.

Why Qalalam? Certified Performance, Local Support

- UAE-based PTA welding and lapping

- In-house metrology lab (CMM, profilometer, roundness tester)

- Full material traceability (MTR with every order)

- API 600/602 and NACE compliance documentation

- Next-day delivery of common sizes (20–150mm diameter)

We don’t just sell cores—we ensure your valves seal when lives and millions depend on it.

Frequently Asked Questions (FAQs)

Q1: Can I lap a worn main valve core in the field?

A: For soft seats (PTFE/graphite): Yes—with proper fixtures.

For metal seats: Not recommended. Field lapping rarely achieves Ra ≤ 0.2µm. We offer refurbishment or replacement.

Q2: What’s the difference between Stellite 6 and Stellite 21?

A:

- Stellite 6: Higher hardness (45 HRC)—best for erosion in steam or clean oil.

- Stellite 21: Higher toughness and corrosion resistance—ideal for H₂S, seawater, or acidic environments.

Q3: Do your cores meet API 600 and NACE MR0175?

A: Yes. All our cores for sour service comply with:

- API 600/602 for dimensional and material requirements

- NACE MR0175/ISO 15156 for hardness and SSC resistance

We provide certificates with every order.

Q4: Can you make custom flow-contoured cores (e.g., equal percentage)?

A: Yes. We CNC-grind:

- Linear, equal percentage, quick-opening profiles

- Multi-stage tapers for anti-cavitation

- Custom radii for noise reduction

Send a flow curve or drawing—we’ll match it.

Q5: Are carbide cores brittle in high-cycle service?

A: Only if misapplied. Our carbide-faced (not full carbide) cores combine tough base metal with hard surface—ideal for slurry service. For high-cycle modulation, we recommend Stellite-faced steel.

Q6: What’s your lead time for Inconel 718 cores?

A: 10–12 days from Dubai. PTA welding and stress relief add time, but we fast-track for critical safety valves.

Q7: Do you offer core refurbishment services?

A: Yes. Our process includes:

- Crack inspection (dye penetrant)

- Removal of old facing

- PTA re-facing with Stellite or carbide

- Precision grinding and lapping

Cost: 40–60% of new, with same warranty.

Precision carbide cores for main valve systems. Models MC01 to MC05 with increasing diameters.

| 🔧 Main Valve Core | |

| Model Code | Size D (mm) |

| MC01 | 26.4 |

| MC02 | 27.7 |

| MC03 | 28.58 |

| MC04 | 29.2 |

| MC05 | 29.6 |

Reviews

There are no reviews yet.