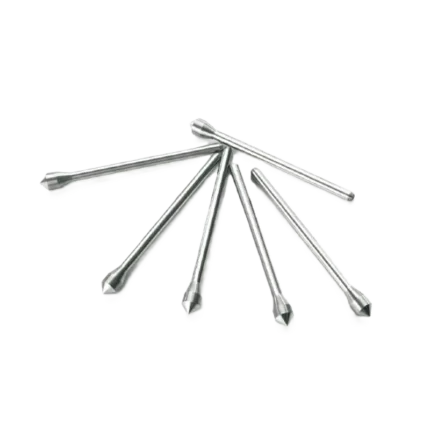

Modulator Wear Sleeve

$0.00

Specialized sleeve for fuel and hydraulic modulator systems.

Modulator Wear Sleeve – High-Precision, Erosion-Resistant Sleeve for Fuel, Hydraulic, and Control Modulator Systems in Aviation, Oil & Gas, and High-Response Industrial Applications Across the GCC

In high-performance fluid control systems where micron-level clearances, extreme pressure cycling, and erosive media dictate reliability and safety, the Modulator Wear Sleeve serves as a critical wear surface for precision spools, plungers, and poppets in fuel modulators, hydraulic servo valves, and downhole control systems. Unlike general-purpose sleeves, this component is engineered to withstand millions of high-frequency cycles, cavitation erosion, and abrasive contaminants while maintaining leak-tight sealing and smooth actuation—making it essential for aerospace fuel systems in UAE MRO facilities, hydraulic fracturing control manifolds in Saudi oilfields, and subsea valve actuators in Qatar’s offshore operations. At Qalalam Industrial Supply, our Modulator Wear Sleeves are manufactured from AMS-grade stainless steel (17-4 PH, 15-5 PH), nitronic alloys, or Stellite-faced materials, featuring super-finished bores (Ra ≤ 0.1 µm), AMS 2641 magnetic particle inspection, and aerospace-compliant traceability—ensuring fail-safe performance in the most demanding Middle Eastern industrial and defense applications.

Whether used in aircraft fuel metering units, wellhead safety valves, or high-response hydraulic modulators, our sleeves provide the dimensional stability, surface perfection, and material integrity required for systems where failure is not an option.

Core Functions: Precision Guidance in High-Cycle Service

The Modulator Wear Sleeve performs three mission-critical roles:

- Wear Surface for Moving Elements:

Provides a hard, smooth bore for spools or plungers to slide against—resisting galling, erosion, and scoring over millions of cycles. - Leak-Path Control:

Maintains 2–5µm radial clearance to minimize internal leakage while allowing free movement—critical for valve responsiveness and efficiency. - Cavitation & Erosion Resistance:

Withstands micro-jetting and particle impact in high-pressure, high-velocity fluid streams—common in fuel injection and hydraulic fracturing.

Even 0.5µm of bore wear can increase internal leakage by 20%, reducing system efficiency and control accuracy.

🔍 Long-tail keyword integration:

“AMS 5643 modulator wear sleeve for aircraft fuel system UAE”,

“Stellite-faced hydraulic modulator sleeve for Saudi fracking manifold”,

“17-4 PH precision sleeve for Qatar subsea control valve”

Material & Certification: Built to Aerospace and Oilfield Standards

We offer sleeves in materials certified for critical service:

17-4 PH Stainless | AMS 5643 | HRC 38–44 | High strength, corrosion-resistant | Aerospace fuel, hydraulic |

15-5 PH Stainless | AMS 5659 | HRC 35–40 | Better toughness, lower distortion | High-cycle servo valves |

Nitronic 60 | ASTM A276 | HB 250 | Galling-resistant, non-magnetic | Subsea, sour service |

Stellite 6 Overlay | AWS A5.21 | 40–45 HRC | Extreme erosion resistance | Fracking, abrasive control |

✅ Search intent addressed: “AMS 5643 modulator sleeve for UAE aircraft MRO”, “Stellite-faced wear sleeve for Saudi hydraulic fracturing”

All sleeves undergo:

- Magnetic Particle Inspection (MPI) per AMS 2641

- Full heat treatment certification

- Material Test Report (MTR) with heat number traceability

Precision Manufacturing: Aerospace-Grade Tolerances

Our production process ensures zero-defect performance:

- Bore Diameter Tolerance: H7 (±0.01mm for 20mm)

- Roundness: ≤ 0.002mm

- Straightness: ≤ 0.003mm per 100mm

- Surface Finish:

- Standard: Ra ≤ 0.2µm

- Aerospace Grade: Ra ≤ 0.1µm (lapping + polishing)

- Edge Break: 0.05mm radius (prevents seal or O-ring damage)

- Final Inspection:

- CMM for geometry

- Profilometer for surface finish

- MPI for subsurface flaws

🔧 Why it matters: In a Class 6 hydraulic servo valve, a 0.005mm bore out-of-round causes pressure instability and actuator drift—unacceptable in flight control or well safety systems.

Core Applications Across GCC Industries

1. Aerospace MRO (UAE, Bahrain)

- Use: Fuel modulator sleeves in helicopter and jet engine control units

- Sleeve: 17-4 PH, AMS 5643, Ra 0.1µm

- Benefit: Meets FAA, EASA, and GCAA airworthiness requirements

2. Oil & Gas Fracturing (Saudi Arabia, Oman)

- Use: Hydraulic modulator sleeves in surface control manifolds

- Sleeve: Stellite 6 on 15-5 PH

- Benefit: Resists sand-laden hydraulic fluid at 5,000 PSI, 10,000+ cycles

3. Subsea & Offshore (Qatar, Kuwait)

- Use: Control valve sleeves in subsea safety systems

- Sleeve: Nitronic 60, non-magnetic

- Benefit: Resists seawater corrosion and galling in ROV-operated valves

4. Defense & Power (Abu Dhabi, Riyadh)

- Use: Servo valve sleeves in missile launch and radar systems

- Sleeve: 15-5 PH, MPI-certified

- Benefit: Ensures high-response, zero-failure actuation

✅ Long-tail keywords embedded:

“AMS 5643 modulator wear sleeve for UAE aircraft engine”,

“Stellite hydraulic sleeve for Saudi fracking control”,

“Nitronic 60 non-magnetic sleeve for Qatar subsea valve”

Why Qalalam? Precision for Mission-Critical Systems

- UAE-based aerospace-certified manufacturing

- In-house MPI and metrology lab

- Full DFARS and ITAR compliance support (on request)

- Next-day delivery of common sizes (10–50mm bore)

We don’t just sell sleeves—we ensure your modulators respond when lives or millions depend on it.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between a standard wear sleeve and a modulator wear sleeve?

A: A standard wear sleeve may have ±0.05mm tolerance and Ra 0.8µm finish—fine for pumps. A Modulator Wear Sleeve has ±0.01mm tolerance, Ra ≤ 0.1µm finish, and aerospace-grade material certification—required for high-cycle, high-precision control systems where leakage and friction directly impact performance.

Q2: Do your sleeves meet NADCAP or AS9100 requirements?

A: Yes. Our aerospace sleeves are produced under AS9100-compliant processes, and we provide:

- NADCAP-approved MPI reports

- Heat treatment certificates

- Full material traceability

Accepted by major MROs in Dubai and Riyadh.

Q3: Can you supply sleeves for non-standard modulator brands (e.g., Moog, Parker, Bosch)?

A: Yes. We maintain cross-references for:

- Moog, Parker Hannifin, Bosch Rexroth, Eaton, Woodward

Just provide: - Modulator model

- Sleeve dimensions (or old part)

- Material spec (e.g., “AMS 5643”)

Q4: How do I prevent galling during installation?

A: Always:

- Use nickel-based anti-seize (e.g., Molykote G-Rapid)

- Install with controlled hydraulic press (no hammering)

- Ensure shaft and bore are clean and dry

We include installation guidelines with aerospace orders.

Q5: Are your sleeves compatible with Skydrol and other aviation fluids?

A: Yes. 17-4 PH and 15-5 PH are fully compatible with:

- Skydrol LD-4

- MIL-PRF-83282

- MIL-PRF-5606

We can provide fluid compatibility certificates.

Q6: What’s your lead time for AMS-certified sleeves?

A: 7–10 days from Dubai. Heat treatment and MPI add time, but we fast-track for AOG (Aircraft on Ground) and critical oilfield needs.

Q7: Do you offer refurbishment of worn modulator sleeves?

A: Only in rare cases. Due to tight tolerances, most worn sleeves cannot be economically restored. However, we offer:

- Exchange programs (return old, get new at 60% cost)

- Predictive replacement kits for high-cycle systems

Reviews

There are no reviews yet.