Sealing Positioning Sleeve

$0.00

Dual-function sleeve for seal alignment and axial positioning.

Sealing Positioning Sleeve – Dual-Function Precision Sleeve for Mechanical Seal Alignment and Axial Positioning in Centrifugal Pumps, Agitators, and Rotating Equipment Across GCC Industries

In the critical interface between rotating shafts and stationary mechanical seals, even 0.05mm of misalignment can cause premature seal failure, leakage, and costly downtime. The Sealing Positioning Sleeve is not a simple spacer—it is a precision-engineered dual-function component that simultaneously ensures perfect concentricity for mechanical seals and accurate axial positioning of impellers, bearings, or coupling halves in pumps, mixers, and compressors across the UAE, Saudi Arabia, Qatar, and beyond. At Qalalam Industrial Supply, our Sealing Positioning Sleeves are manufactured from stainless steel 316, hardened carbon steel, or tungsten carbide, featuring micron-level tolerances, mirror-finish sealing surfaces, and OEM-compatible geometries—ensuring reliable, leak-free operation in demanding applications from desalination plants and oil refineries to district cooling systems and chemical processing facilities.

Unlike generic sleeves that only space components, the Sealing Positioning Sleeve integrates seal journal accuracy with axial reference functionality in a single monolithic piece—eliminating stack-up errors from multiple parts and ensuring that mechanical seals run concentrically under thermal and dynamic loads. Whether used as a replacement for OEM sleeves in Grundfos, KSB, or Sulzer pumps or as a custom solution for agitators in GCC chemical plants, this sleeve delivers the dimensional stability, surface quality, and corrosion resistance that maintenance engineers depend on for extended MTBF (Mean Time Between Failures).

Dual-Function Design: Why One Sleeve Does Two Jobs

The Sealing Positioning Sleeve solves two common failure modes in rotating equipment:

- Seal Misalignment:

The precision-ground sealing journal (Ra ≤ 0.4 µm) ensures the mechanical seal’s stationary face runs parallel to the rotating face—preventing face distortion, heat buildup, and leakage. - Axial Drift:

The shoulder or step geometry provides a positive stop for impellers, bearings, or thrust collars—maintaining correct clearance under thermal expansion or hydraulic thrust.

This integrated design reduces part count, simplifies assembly, and improves overall reliability.

🔍 Long-tail keyword integration:

“sealing positioning sleeve for Grundfos pump UAE”,

“stainless steel seal alignment sleeve for desalination Saudi Arabia”,

“OEM replacement positioning sleeve for KSB agitator Qatar”

Material Selection: Matched to Fluid and Duty

We offer Sealing Positioning Sleeves in materials engineered for your service:

SS 316/316L | Corrosion-resistant, non-magnetic | Water, chemicals, food-grade, seawater |

Hardened Carbon Steel (HRC 55+) | High strength, cost-effective | Oil, gas, general industrial |

Tungsten Carbide | Extreme wear resistance | Slurry, sand, abrasive media |

Duplex 2205 | High strength + chloride resistance | Offshore, desalination, sour service |

✅ Search intent addressed: “best material for sealing sleeve in seawater pump”, “carbide positioning sleeve for slurry agitator UAE”

All sleeves undergo stress-relief annealing to prevent dimensional drift after installation.

Precision Manufacturing: Tolerances That Prevent Seal Failure

Our production process ensures seal-compatible accuracy:

- Sealing Journal Diameter: h6 tolerance (±0.009mm for 30mm)

- Surface Finish: Ra ≤ 0.4 µm (standard), Ra ≤ 0.2 µm (for high-speed seals)

- Concentricity: ≤ 0.01mm between journal and mounting ID

- Shoulder Perpendicularity: ≤ 0.01mm

- Length Tolerance: ±0.05mm

🔧 Why it matters: A 0.02mm runout on the sealing journal causes uneven face loading—leading to seal hang-up, chattering, or rapid wear.

Core Applications Across GCC Industries

1. Desalination & Water (UAE, Saudi)

- Use: Seal sleeves in high-pressure SWRO feed pumps

- Sleeve: SS 316L, Ra 0.2 µm

- Benefit: Prevents seal failure in 45,000 ppm seawater, extends life by 3x

2. Oil & Gas Refining (Qatar, Kuwait)

- Use: Positioning sleeves in crude oil transfer pumps

- Sleeve: Hardened carbon steel

- Benefit: Maintains impeller clearance at 200°C

3. Chemical Processing (Oman, Bahrain)

- Use: Agitator shaft sleeves in reactor mixers

- Sleeve: SS 316, dual-shoulder design

- Benefit: Ensures seal alignment + impeller positioning in one part

4. District Cooling (Dubai, Abu Dhabi)

- Use: Replacement sleeves for Grundfos NB/NK pumps

- Sleeve: SS 316, OEM dimensions

- Benefit: Direct drop-in replacement—no rework needed

✅ Long-tail keywords embedded:

“SS 316 sealing positioning sleeve for SWRO pump UAE”,

“OEM Grundfos seal sleeve replacement Saudi”,

“chemical-resistant positioning sleeve for reactor agitator Qatar”

OEM Cross-Reference & Replacement

We maintain databases for major pump and agitator brands:

- Grundfos: NB, NK, CR series

- KSB: Etanorm, Movitec

- Sulzer: ACP, APP

- Flowserve, Ebara, Xylem

Just provide:

- Pump/agitator model

- Shaft diameter

- Seal type (cartridge, pusher)

We deliver a direct-fit, upgraded-material replacement—often with longer life than OEM.

Why Qalalam? Precision You Can Trust

- Local UAE inventory of common sizes (10–80mm shaft)

- In-house grinding and lapping—no outsourcing

- Full material traceability (MTR with every order)

- Seal compatibility testing with John Crane, EagleBurgmann specs

We don’t just sell sleeves—we protect your mechanical seals.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between a sealing sleeve and a positioning sleeve?

A: Traditionally, these were two separate parts. A sealing sleeve only provides the smooth journal for the seal. A positioning sleeve only sets axial location. Our Sealing Positioning Sleeve combines both in one precision part—reducing misalignment risk and simplifying assembly. In high-speed or high-temperature pumps, this integration is critical for reliability.

Q2: Can I use a standard spacer sleeve instead?

A: Not recommended. Standard sleeves lack the surface finish (Ra ≤ 0.4 µm) and concentricity (≤0.01mm) required for mechanical seals. Using one causes seal hang-up, leakage, or rapid face wear—especially with cartridge seals.

Q3: Do your sleeves work with all mechanical seal brands?

A: Yes. Our sealing journals meet international surface finish and tolerance standards compatible with:

- John Crane

- EagleBurgmann

- Flowserve

- Burgmann

- AESSEAL

If you provide your seal model, we’ll verify compatibility.

Q4: How do I install the sleeve without damaging the sealing surface?

A: Always:

- Use a shoulder driver (never hammer on the journal)

- Apply anti-seize lubricant to the shaft

- Heat the sleeve to 150°C for thermal fit (if interference fit)

We include a free installation guide with every order.

Q5: Are your sleeves suitable for high-speed pumps (>3,600 RPM)?

A: Yes. For high-speed service, we recommend:

- SS 316 or carbide (better thermal stability)

- Ra ≤ 0.2 µm finish

- Dynamic balancing (available on request)

Q6: What’s your lead time for custom OEM replacements?

A: 3–5 days for standard materials from Dubai. We keep common Grundfos and KSB sizes in stock for next-day delivery.

Q7: Can you refurbish worn sealing sleeves?

A: Regrinding: yes—if enough wall thickness remains (min. 1mm). We restore diameter and surface finish to as-new condition. Cost: 40–60% of new.

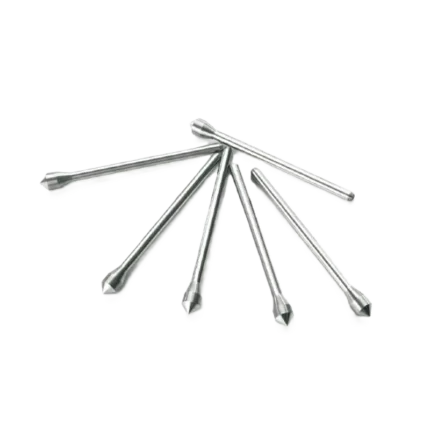

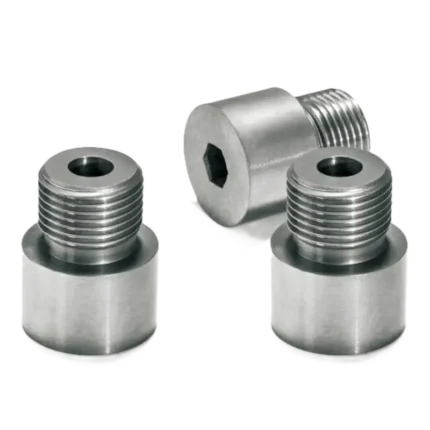

Models MF01, MF02, MF03. Ensures both sealing and alignment.

| 🔧 29. Sealing Positioning Sleeve | |||

| Model Code | D (mm) | H (mm) | h (mm) |

| MF01 | 27 | 25 | 18 |

| MF02 | 33 | 25 | 18 |

| MF03 | 33 | 26 | 21 |

Reviews

There are no reviews yet.